Loading ...

Loading ...

Loading ...

04 GB

CONVERSION FOR DIFFERENT GAS TYPES

Follow the steps given below to convert the

appliance from the factory set up to that for a

different gas type.

Changing the gas inlet connector nuts to

adjust the oven for Natural Gas

Use the pipe (2) given with the appliance for

natural gas or industrially produced gas.

Ovens adjusted for

LPG

The same pipe can be used for industrially

produced gas and LPG. Insert pipe (1) for LPG

Adjustments and changing injectors

Changing Injectors

•Remove grates.

•Remove burner caps and burners.

•Remove injectors by using a 7 mm wrench, then screw on the correct

injector selected from table

2 according to the gas

to be used.

•Follow the above steps in the reverse order after completing the

assembly of the new injector.

Stand by Adjustment

For stand by adjustment

•Turn the burner control knob to the small

flame position and remove the knob.

•If conversion from LPG to natural gas is

required, turn clockwise

the by-pass screw of

the gas valves with a screw driver to their final

position.

•If conversion from LPG to natural gas is

required, turn anti-clockwise the by-pass screw

of the gas valves with a screw driver till a

smaller flame of ¼ size is obtained.

•After completing the adjustment, insert the

knobs again.

•Check the adjustment by turning the burner control knob quickly from

maximum to minimum position. If the flame does not go out, it means

that the adjustment is correct.

GAS CONNECTION

The gas must be connected to the appliance according to standard

and the provisions in force.

•When the appliance left the factory, it was regulated for the gas type

stated on the adhesive info label near the gas inlet at the back of the

appliance.

Make sure that you are using the

gas stated on the label. If it is a

different type of gas, follow the instructions in the chapter on

conversion to different gas types'.

•Make sure that gas supply pressure is that given in the table 'below in

order to achieve maximum efficiency and lowest consumption. If the

gas pressure

is different, a proper gas regulator should be used on the

gas inlet. The use of a gas regulator complying with the standards for

LPG is allowed.

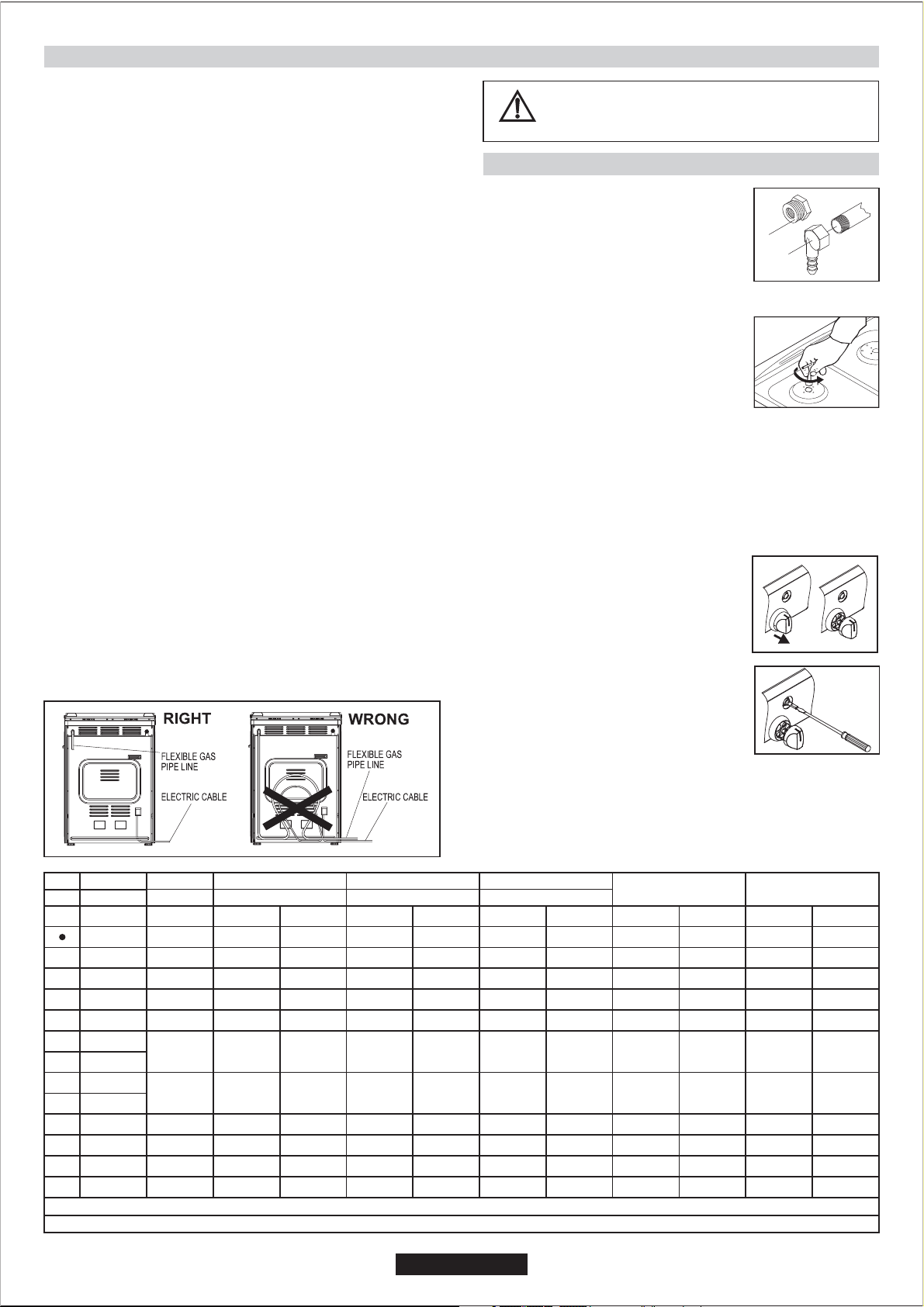

Connection with a Solid or Flexible Metal Pipe

•The gas supply can be connected by a proper flexible stainless steel

pipe according to the

safety standards in force. In this case, there will

be no further need to move the appliance. The gas inlet connector of

the appliance is Gc ½.

Connection with a Flexible Non-metallic Pipe

•If the gas connection is in a position where it can be switched on and

off when required,

a flexible pipe complying with the standards in force

can be used. The flexible pipe must be firmly fixed with a clamp.

•The flexible pipe can be connected as follows:

•Since the flexible pipe will be placed behind the oven, it should be

exposed to temperatures no higher than 30ºC at any

point.

•The length should be no longer than 150 cm.

•It must not be exposed to steam.

•No folding, bending or tension is allowed.

•It should be protected against sharp or piercing objects.

•It must be accessible in order to allow for periodic inspection.

•The flexible pipe must be checked as follows to

guard against wear

over time:

•Check that there are no cracks, cuts or burned spots on or at the ends

of the pipe.

•The material must maintain its flexibility. Excessive rigidity is not

allowed.

•There must be no rust on the clamps.

•It should be replaced in any case after no more than

5 years' usage.

Check all connections for leaks with a soapy substance

after the installation is completed. Do not use a flame

for to check gas leaks.

1

2

Gas

G 20

G 25

G 25

G 30

G 31

G 30

G 31

G 30

G 31

G 20

G 25.1

G 2.350

G 27

Front Right

auxiliary

Left

semi-rapid

Black Right

rapid

Oven burner Grill burner

kW = power

• Factory setting : G 20 - 20 mbar / G 25 - 25 mbar

mbar

20

25

20

29

37

50

37

25

25

13

20

Jet

0.83

0.83

0.90

0.50

0.50

0.45

0.50

0.83

0.83

1.10

0.90

kW

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.10

1.00

1.00

1.00

Jet

1.00

1.00

1.10

0.65

0.65

0.60

0.65

1.00

1.00

1.35

1.10

kW

1.70

1.70

1.70

1.70

1.70

1.70

1.75

1.85

1.70

1.70

1.70

Jet

1.20

1.20

1.35

0.85

0.85

0.70

0.85

1.20

1.20

1.70

1.35

kW

2.70

2.70

2.70

2.70

2.70

2.70

2.95

2.95

2.65

2.70

2.70

Jet

1.10

1.10

1.20

0.70

0.70

0.65

0.70

1.10

1.10

1.55

1.20

kW

2.3

2.25

2.3

2.3

2.3

2.3

2.30

2.35

2.10

2.30

2.30

Jet

1.10

1.10

1.20

0.70

0.70

0.65

0.70

1.10

1.10

1.25

1.20

kW

2.25

2.2

2.25

2.25

2.25

2.25

2.30

2.30

2.10

2.25

2.25

Loading ...

Loading ...

Loading ...