Loading ...

Loading ...

Loading ...

4 | English

SITE PREPARATION

Preparation

WARNING

To avoid a hazard due to instability of the appliance, it

must be xed in accordance with the instructions.

Uncrate the unit and inspect for damage. Remove the wood

base and discard shipping bolts and brackets. Remove and

recycle packing materials. Do not discard the kickplate, anti-

tip bracket and hardware.

Remove the kickplate by extracting the two mounting

screws. Refer to the illustration below.

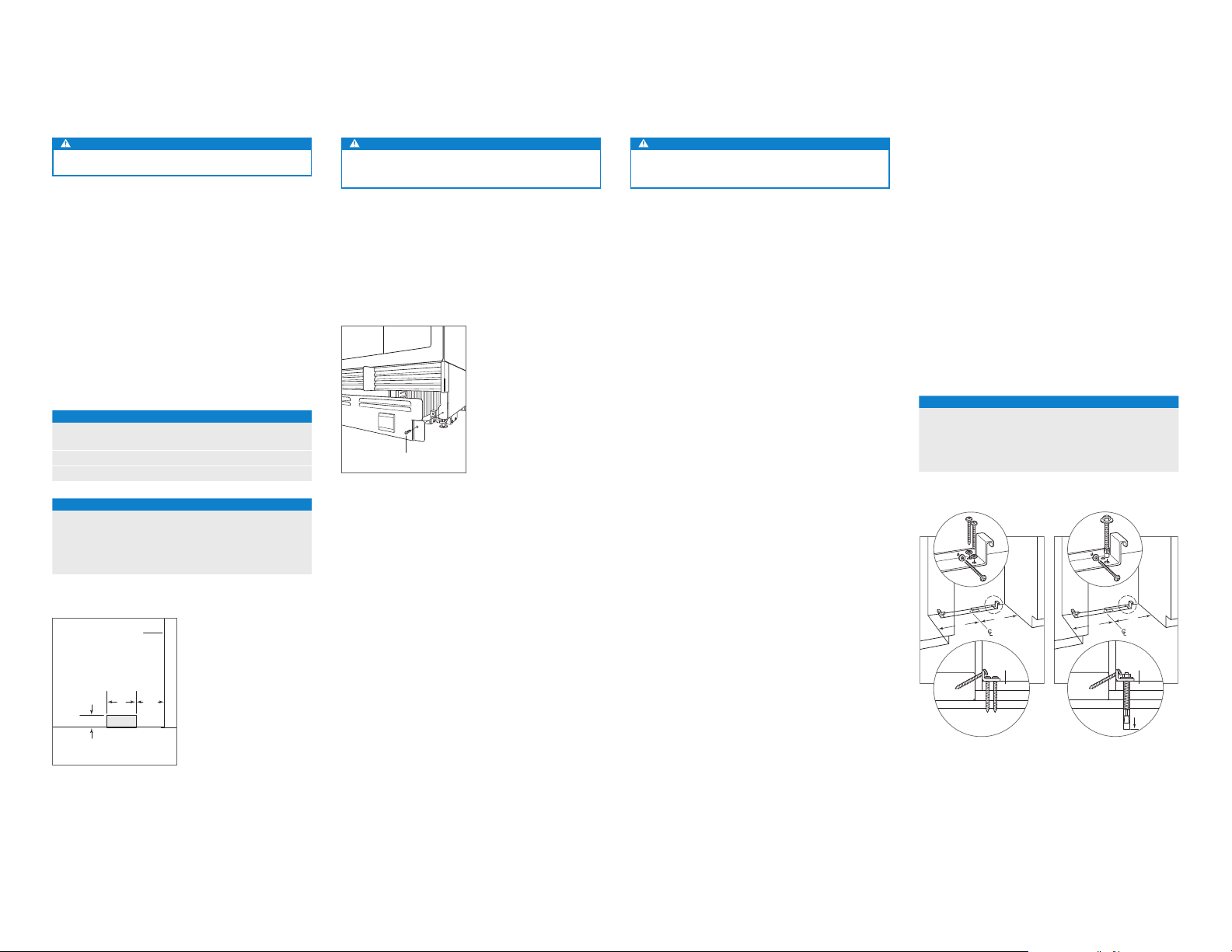

Anti-Tip Bracket

WARNING

To prevent the unit from tipping forward, the anti-tip

bracket must be installed.

The back of the anti-tip bracket must be installed 610 mm

from the front of the unit (without panels).

Use all anti-tip bracket hardware as instructed for wood or

concrete oors.

IMPORTANT NOTE: For wood or concrete oor applications,

if the #12 screws do not hit a wall stud or wall plate, use the

#8 screws and #12 washers with the wall anchors.

IMPORTANT NOTE: In some installations the subooring or

nished oor may necessitate angling the screws used to

fasten the anti-tip bracket to the back wall.

SCREW

Kickplate removal

WOOD FLOOR APPLICATION

After properly locating the anti-tip bracket in the opening,

drill pilot holes 5 mm diameter maximum in the wall studs or

wall plate. Use the #12 screws and washers to secure the

brackets. Verify the screws penetrate through the ooring

material and into wall studs or wall plate a minimum of 19

mm. Refer to the illustration and chart below.

CONCRETE FLOOR APPLICATION

After properly locating the anti-tip bracket in the opening,

drill pilot holes 5 mm diameter maximum in the wall studs

or wall plate. Drill 10 mm diameter holes into the concrete a

minimum of 38 mm deep. Use the #12 screws and washers

to secure the brackets to the wall, and use the

3

/8" wedge

anchors to secure the brackets to the oor. Verify the screws

penetrate wall studs or wall plate a minimum of 19 mm.

Refer to the illustration and chart below.

ANTI-TIP BRACKET PLACEMENT

WIDTH A

457 mm Models 229 mm

610 mm Models 305 mm

762 mm Models 381 mm

914 mm Models 457 mm

A

A

SUBFLOORING

WOOD FLOOR

WALL PLATE

FINISHED

FLOORING

A

A

SUBFLOORING

CONCRETE

FLOOR

WALL PLATE

FINISHED

FLOORING

38 mm

min

Wood oor

Concrete oor

Plumbing

WARNING

Connect to potable water supply only.

Installation must comply with all applicable plumbing codes.

The water supply line should be located within the shaded

area shown in the illustrations below. The water supply line

should be connected to the house supply with an easily

accessible shut-off valve. Do not use self-piercing valves.

The water supply line must be ush to the oor and not

interfere with installation of the anti-tip bracket.

An in-line lter is required for models with an ice maker or

water dispenser when water conditions have a high sedi-

ment content.

A reverse osmosis system can be used provided there

is constant water pressure of 2.4–8.3 bar supplied to the

unit at all times. A copper line is not recommended for this

application.

PLUMBING REQUIREMENTS

Water Supply Line

1

/4" OD copper, braided

stainless steel or PEX tubing

Water Pressure 2.4–8.3 bar

Excess Water Line for Connection .9 m

WATER SUPPLY LOCATION

WIDTH A

457 mm Models 76 mm

610 mm Models 140 mm

762 mm Models 152 mm

914 mm Models 229 mm

76 mm

FRONT VIEW

FLOOR

TOP VIEW

BACK WALL

13 mm

152

mm

A

WATER

LINE

A

152

mm

RIGHT SIDE

OF OPENING

RIGHT

SIDE OF

OPENING

Water supply location

Loading ...

Loading ...

Loading ...