Loading ...

Loading ...

Loading ...

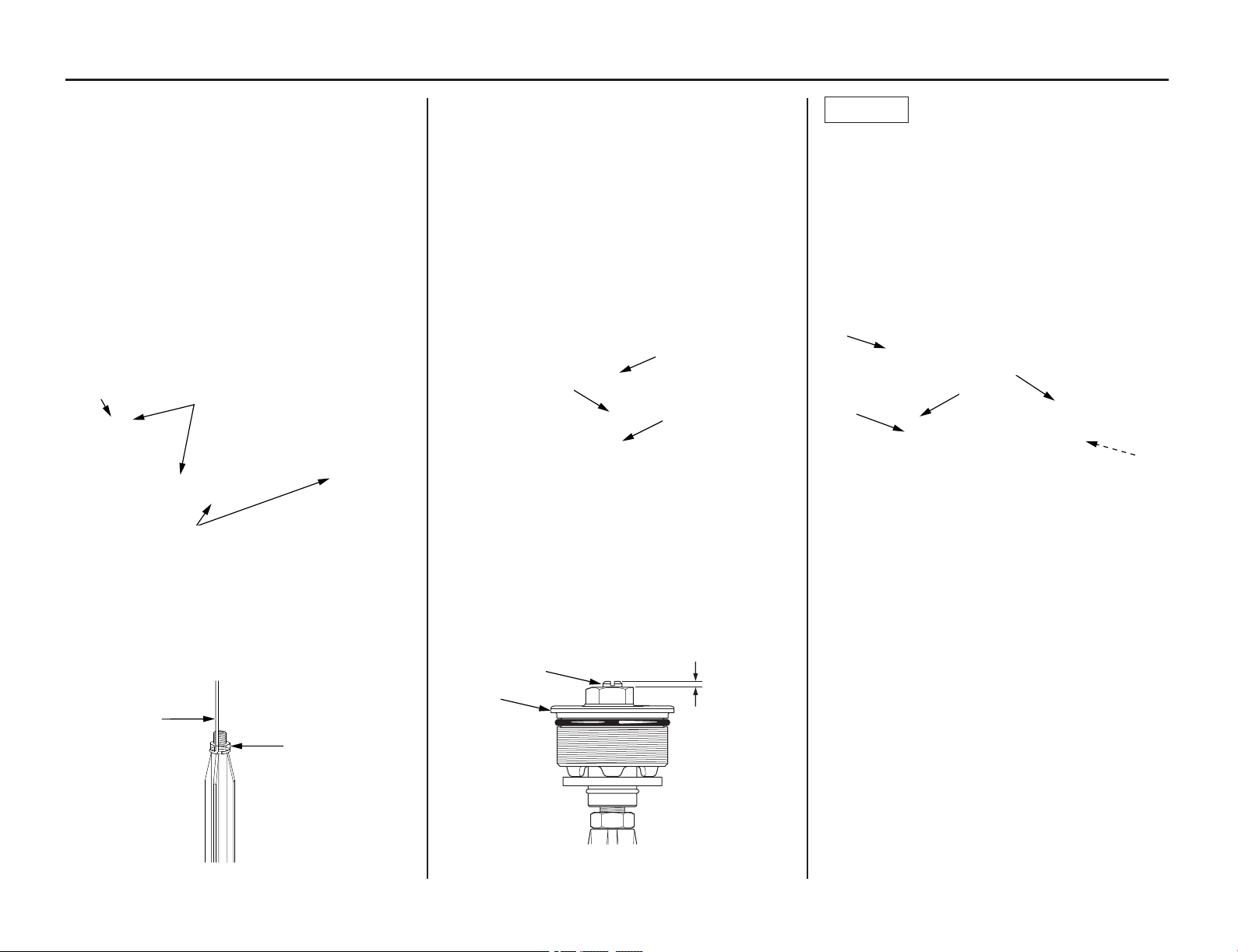

(15)

(16)

(2)

(16)

(2)

98 Adjustments for Competition

Front Suspension Adjustments

(21)

(16)

17. Clean the spring and spring seat thoroughly

with a high flash point solvent to remove all

metal particles and dirt.

18. Dry the spring and spring seat with air

pressure rather than a shop towel. Using a

shop towel allows lint to stick to the springs.

Lint or any particles that stick in the damping

passages can cause inconsistent damping.

19. Turn the adjuster needle rod (14)

counterclockwise and remove it from the fork

cap (2).

Check the adjuster needle rod for bent or

damage.

Check that the O-rings (20) on the fork cap

and needle rod are in good condition. Apply

the recommended fork oil to the O-rings.

(2) fork cap (20) O-rings

(14) adjuster needle rod

20. Loosen the lock nut (16) slightly.

21. Attach a two-foot length of mechanic’s

wire (21) to the threaded portion on the lock

nut. Wrap the wire securely around the threads.

(16) lock nut (21) mechanic's wire

22. Install the fork spring (17) as follows:

– With the fork spring held upright on its

marked end, feed the mechanic’s wire up

through the spring.

– Angle the fork spring and slowly slide it

down into the fork using a gentle rocking

motion.

23. Reaching through the two adjacent coils near

the oil lock valve, hold the spring guide (22)

with your finger.

Remove the mechanic’s wire and hand

tighten the lock nut (16) to the spring guide

(22).

(22)

(16)

(17)

(16) lock nut (22) spring guide

(17) fork spring

24. Set the adjuster screw (12) to 0.06 in

(1.5mm) from the fork cap (2) top, then

install the fork cap onto the piston rod.

(2) fork cap (12) adjuster scre w

When installing the fork cap, be careful not to

damage the damping force adjuster needle rod

and the needle or the rod end.

25. Hand tighten the fork cap (2) on the piston

rod (15) lightly until it stops, then tighten the

lock nut (16) to the fork cap to the specified

torque:

15 lbf·ft (19.7 N·m, 2.0 kgf·m)

NOTICE

(2) fork cap (16) lock nut

(15) piston rod

26. Temporarily thread the fork cap into the fork

tube.

27. Insert both fork legs into the fork clamps.

(12)

(2)

0.06 in

(1.5 mm)

(2)

(20)

(14)

Loading ...

Loading ...

Loading ...