Loading ...

Loading ...

Loading ...

INSTALLATION

8

NOTICE:

Since the tightly wound tape is the only means

of keeping water out of the splice, the eciency of the

splice will depend on the care used in wrapping the tape.

NOTICE: For wire sizes larger than #8, (7mm

2

) use a sol-

dered joint rather than Scotchl putty.

Wire Splicing

Splice wire to motor leads using only copper wire for

connections to pump motor and control box.

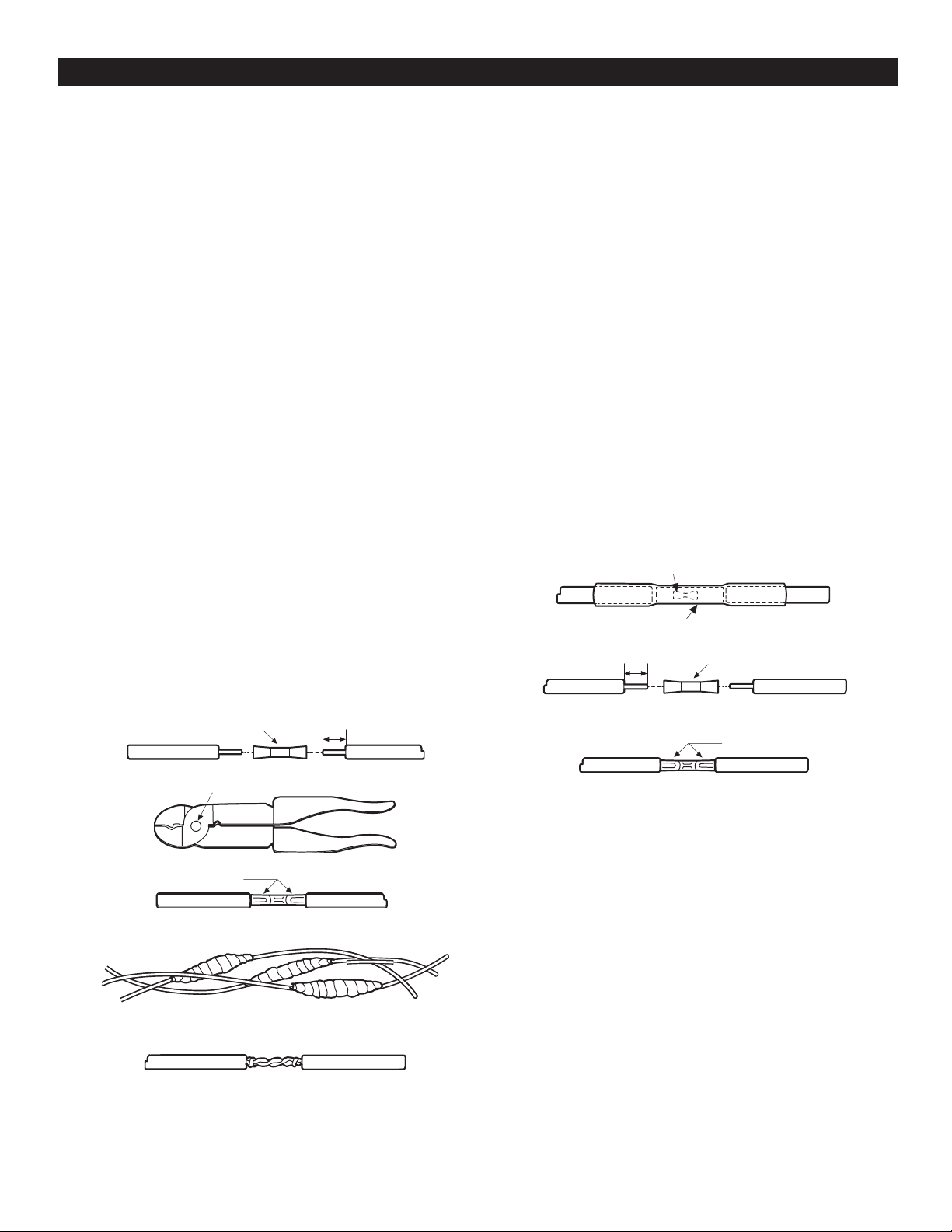

1. Tapered splice (Wire sizes No. 8 and larger):

A. Cut motor lead staggering lead and wire length

so that second lead is 2” longer than rst lead and

third lead is 2” longer than second.

B. Cut o power supply wire ends. Match colors and

lengths of the wires to colors and lengths of motor

leads.

C. Trim installation back 1/2” from supply wire and

motor lead ends.

D. Insert motor lead ends and supply wire ends into

butt connectors. Match wire colors between supply

wires and motor leads.

E. Using crimping pliers, indent butt connector lugs to

attach wire.

F. Cut electrical “Scotchl™” or equivalent insulation

putty into three equal parts and form tightly around

butt connectors. Be sure Scotchl™ overlaps

insulted part of wire.

G. Using #33 Scotch™ or equivalent tape, wrap each

joint tightly; cover wire for about 1-1/2” on each

side of joint. Make four passes with the tape. When

nished you should have four layers of tape tightly

wrapped around the wire. Press edges of tape

rmly down against the wire.

NOTICE: Since tightly wound tape is the only

means of keeping water out of splice, eciency of

splice will depend on the care used in wrapping the

tape.

NOTICE: For wire sizes larger than No. 8, use

soldered joint rather than Scotchl™ putty.

2. Heat shrink splice

[for wire sizes #14, 12 and AWG (2,3 and 5mm)]

A. Remove 3/8” insulation from ends of motor leads

and power supply wires.

B. Put plastic heat shrink tubing over motor leads

between power supply and motor.

C. Match wire colors and lengths between power

supply and motor.

D. Insert supply wire and lead ends into butt

connector and crimp. Match wire colors between

power supply and motor. Pull leads to check

connections.

E. Center tubing over butt connector and apply heat

evenly with torch (match or lighter will not supply

enough heat).

NOTICE: Keep torch moving. Too much concen-

trated heat may damage tubing.

3. Mechanical Splice Kit with plastic insulators (for 14, 12

and 10 Gauge AWG Wire (2, 3 and 5mm):

A. Cut motor leads staggering lead and wire length so

that 2nd lead is 4” (101.6mm) longer than 1st lead and

3rd lead is 4” (101.6mm) longer than second.

B. Cut wire ends matching colors and lengths of wires

between power supply and motor.

C. Trim insulation back 1/2” (12.7mm) from power supply

wire and motor lead ends.

D. Unscrew plastic caps from insulators. Place a cap

and neoprene gasket sleeve on each wire to be

spliced.

E. Slide insulator body onto one wire end.

F. Insert wire end into butt connector and crimp.

Match wire colors between power supply and motor

G. Center insulator body over splice and slide gasket

sleeves into body as far as they will go. Screw caps

onto insulator body and tighten by hand for a strong,

waterproof splice.

Notch

1/2” (12.7mm)

1/2” (12.7mm)

Indent here

Connector

Butt Connector

Heat Shrink Tubing

Butt Connector

Indent here

Completed Splice

Alternate Method

twist and solder

Loading ...

Loading ...

Loading ...