Loading ...

Loading ...

Loading ...

Westinghouse Portable Power | 19

Spark Plug Maintenance - Continued from page 18

7. Place a clean rag over the opening created by the

removal of the spark plug to make sure no dirt can

get into the combustion chamber.

8. Inspect the spark plug for:

• Cracked or chipped insulator

• Excessive wear

• Spark plug gap of 0.032 in. (0.80 mm).

If the spark plug fails any one of the

conditions listed above, replace the plug.

NOTICE

Only use the recommended spark plug. See chart

below. Using a non- recommended spark plug could

result in damage to the engine.

9. Install the spark plug by carefully following the

steps outlined below:

a. Carefully insert the spark plug back into the

cylinder head. Hand-thread the spark plug until

it bottoms out.

b. Using the spark plug socket wrench provided,

turn the spark plug to ensure it is fully seated.

c. Replace the spark plug boot, making sure the

boot fully engages the spark plug’s tip.

d. Install the spark plug access cover.

Recommended Spark Plug Replacement:

Westinghouse

Model Number

Torch Spark

plug

Champion Bosch Autolite

iGen4500

F7RTC N9YC W7DC 52

CLEANING THE SPARK ARRESTOR

Check and clean the spark arrestor after every 100

hours of use or 6 months.

1. Stop the inverter and let it cool for several minutes

if running.

2. Move the inverter to a at, level surface.

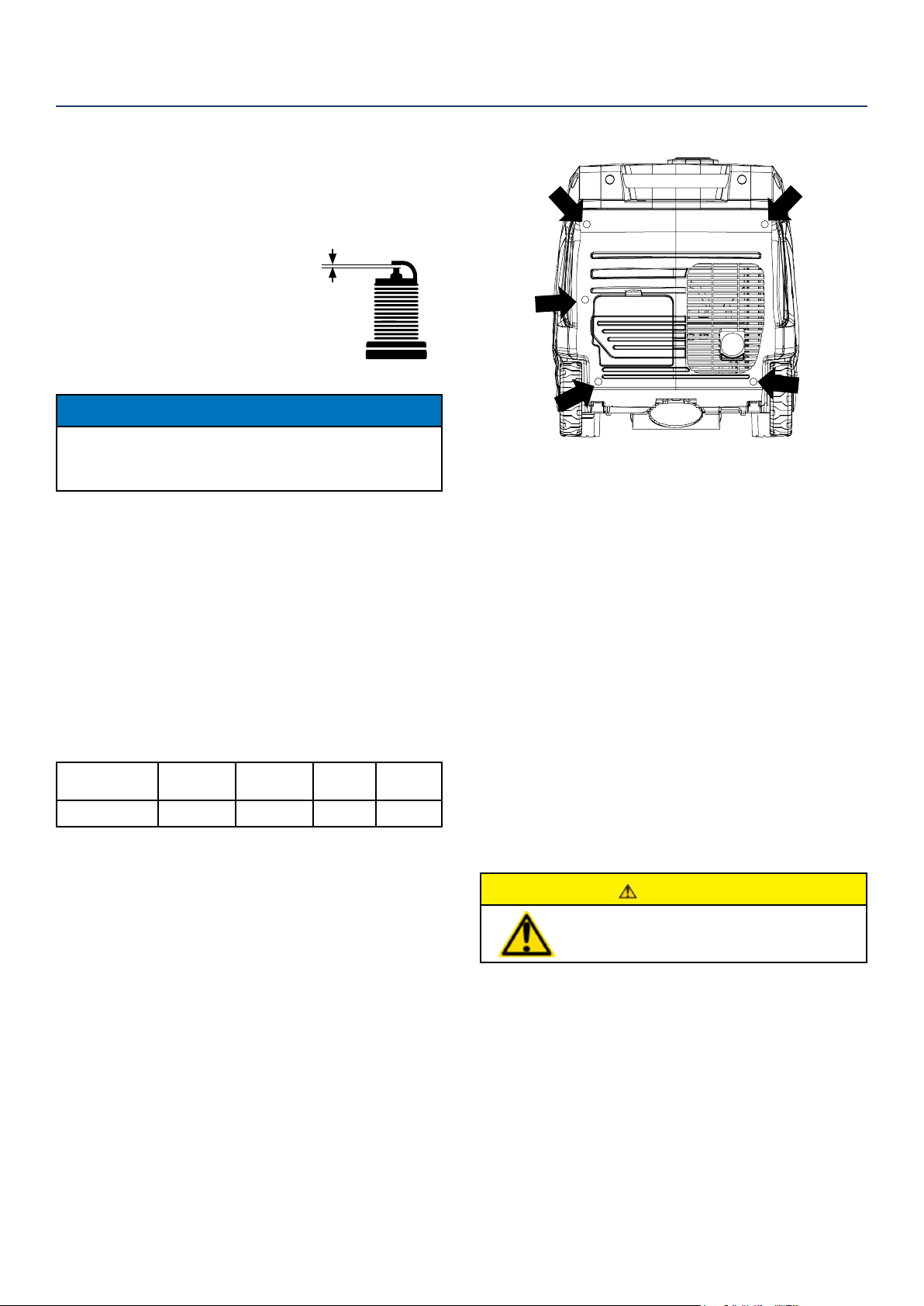

3. Remove the screws holding the muer cover in

place (see Figure 20).

4. Loosen the clamp holding the spark arrestor onto

the muer.

5. Slide the spark arrestor band clamp o the spark

arrestor screen.

6. Pull the spark arrestor screen o the muer

exhaust pipe.

7. Using a wire brush, remove any dirt and debris that

may have collected on the spark arrestor screen.

8. If the spark arrestor screen shows signs of wear

(rips, tears or large openings in the screen), replace

the spark arrestor screen.

9. Install the spark arrestor components in the

following order:

a. Place spark arrestor screen over the muer

exhaust pipe. Push on the screen until it fully

bottoms out.

b. Place the spark arrestor band clamp over the

screen and tighten with a athead screwdriver

10. Replace the discharge gate.

CHECKING AND ADJUSTING VALVE LASH

CAUTION

Checking and adjusting valve lash

must be done when the engine is cold.

1. Remove the rocker arm cover and carefully remove

the gasket. If the gasket is torn or damaged, it must

be replaced.

2. Remove the spark plug so the engine can be

rotated more easily.

3. Rotate the engine to top dead center (TDC) of the

compression stroke. Looking through the spark

plug hole, the piston should be at the top.

SPARK PLUG GAP

MAINTENANCE

Figure 20: Remove Muer Access Panel

Loading ...

Loading ...

Loading ...