Loading ...

DO NOT remove the thermal insulation from sleeve.

Never drill or install fasteners through bottom of sleeve.

Protect wall sleeve during interior and exterior surface cleaning

from corrosive and acidic chemicals. These types of chemicals

will cause paint damage and premature rusting of the wall sleeve.

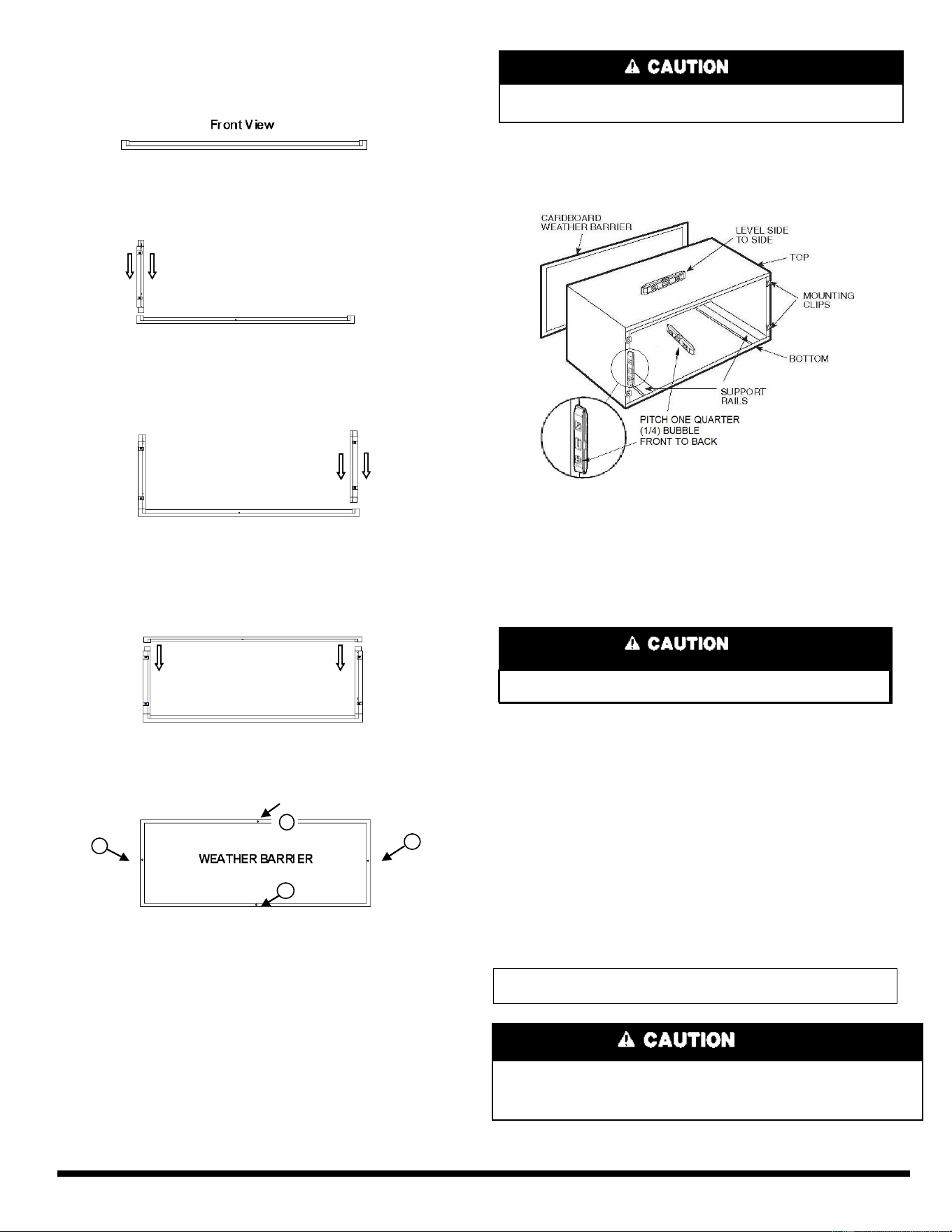

ASSEMBLE WALL SLEEVE

Step 1 Set Bottom Panel on a clean flat and level surface.

Step 2 Locate Left Side Panel. Align panel in the Left Bottom

Panel slot. Fully insert Left Panel into Bottom Panel until

locking tabs engage.

Front View

Step 3 Locate Right Side Panel. Align panel in the Right

Bottom Panel slot. Fully insert Right Panel into Bottom Panel

until locking tabs engage.

Front View

Step 4 Locate Top Panel and align with top of Right and

Left Side Panels. Fully insert Top Panel into Right and Left

Side Panels until locking tabs engage.

Front View

Step 5 (If required) Locate Weather Barrier and attach to the

rear of the assembled sleeve with four (4) supplied push pins.

Rear View

SLEEVE INSTALLATION

Step 1 Prepare Sleeve —

If grille is to be installed at this time,

remove and discard weather barrier panel and install rear grille per

the manufacturer's instructions. If condensate drain tube is to be

installed at this time, install per the manufacturer's instructions.

Step 2 Setting Sleeve —

Position the fully assembled sleeve in

the wall opening with the bottom down and the drain holes

toward the outdoors.

Sleeve must extend at least

5

/

8

inches beyond building exterior to

assure proper drainage and to allow weather tight seal. Sleeve must

extend at least

1

/

4

inches into room for proper weatherproofing.

Step 3 Leveling Sleeve

—

Place level in locations shown

in Figure 2. Sleeve must be mounted level side to side and a

1/4 bubble tilt front to back. Use shims as required to insure

proper level. This will allow for proper condensate drainage.

Step 4 Fastening Sleeve to Wall

—

Locate and mark

two (2) holes on each side approximately 4-inches from the

bottom and 4-inches from the top.

Drill 3/16-in. pilot holes and use #10 x 1-in. screws, or

appropriate fasteners for the wall construction, to secure

sleeve in place. It is recommended that washers are used to

prevent driving the screw head through the side wall.

Check the sleeve is level side to side and a 1/4 bubble tilt

front to back. Adjust if necessary. See Figure 2.

Step 5 Exterior Weather Proofing —

Proper weather

proofing of all sides between the wall surface and sleeve is

essential to assure a trouble-free installation.

Apply sealant, caulking or equivalent weather proofing

material around the perimeter of the sleeve to eliminate

outdoor air and water leaks into the room.

Step 6 Interior Weather Proofing —

Apply sealant,

caulking or equivalent weather proofing material to joints

around the perimeter ( including bottom) of the sleeve to

create a total air seal.

Note

: Expandable foam insulation may be added to fill large

wall gaps. Apply per manufacturer's instructions.

4

1

3

1

2

1

1

Figure 2

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. FAP110-2000-01 Printed in U.S.A. Form SnapEase Metal Sleeve 4-27-2017 Pg 2