Documents: Go to download!

User Manual

- User Manual - (English, French, Spanish)

- Specification Sheet - (English)

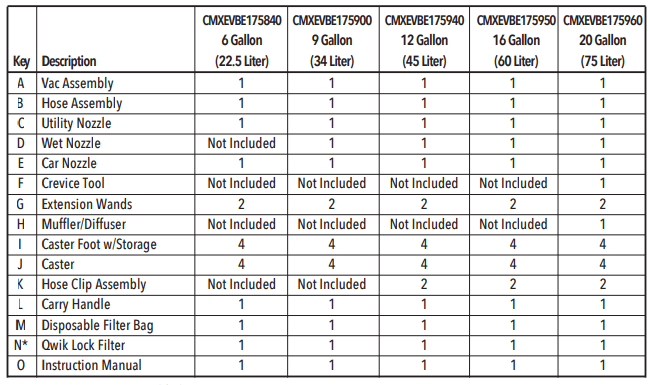

- CARTON CONTENTS (Fig. B)

- INSTALLATION

- OPERATION

- MAINTENANCE

Table of contents

User manual Vacuum

CARTON CONTENTS (Fig. B)

* Items may come preassembled.

Images shown may not reflect actual part.

Remove entire contents of carton. Check each item against the Carton Contents List.

If any parts are damaged or missing, immediately call customer service at 1-888-331-4569 (Mexico 001-881-331-4569).

-504341.png)

Tools Required:

-492435.png)

INSTALLATION

Caster/Caster Foot Assembly (Fig. C)

- Remove the Powerhead Assembly from the Dust Drum and set aside.

- Turn the Dust Drum upside down on the floor.

- Insert the Caster Feet into the bottom of Drum, as shown (4 places).

- Push on the Caster Foot until the Foot is flush with bottom of the Dust Drum.

- Insert the Caster Stem into the Socket of the Caster Foot, as shown (4 places).

- Push on the Caster until the Ball on the Caster Stem is inserted all the way into the Socket. You will hear the Ball snap into the Socket and the Caster will swivel easily when positioning is correct.

- Turn the Drum upright.

-795807.png)

Hose Clip Assembly (Fig. D)

(Models CMXEVBE175940, CMXEVBE175950, CMXEVBE175960)

- Align the Hose Clips in the recessed areas on the Powerhead Assembly.

- Insert Screw and tighten to fasten the Hose Clip to the Powerhead Assembly

-36468.png)

Carry Handle Assembly (Fig. E)

Place the Carry Handle on the Wet/Dry Vac Powerhead Assembly.

Tighten both Screws to assemble the Carry Handle on the Powerhead Assembly

-265326.png)

Vac Assembly (Fig. F)

- Line up front (label side) of Powerhead Assembly with Vac Inlet located on the front of the Drum.

- NOTE: Powerhead Assembly must be aligned with Drum for proper attachment.

- Place Powerhead Assembly on top of Drum.

- Be sure Powerhead Assembly completely covers the top of the Drum so leakage does not occur.

- Press down on the Lid Latches to securely attach the

- Powerhead Assembly to the Drum.

- To remove the Powerhead Assembly, first unplug the unit from the electrical outlet. Then lift up on the Lid

- Latches and remove from Drum.

-468993.png)

Insert Hose (Fig. G)

Insert the Locking End of the Hose Assembly into the Vac Inlet. The Hose should snap into place.

To remove the Hose from the Vac, press the Release Button on the Hose Assembly and pull the Hose out of the Vac Inlet, as shown.

-669160.png)

Accessory Storage (Fig. H)

Your Accessories may be stored in the Caster Feet or in the storage locations on the Powerhead Assembly (in applicable models).

The Hose may also be stored by wrapping it around the unit and securing it into the Hose Clips (in applicable models).

-90809.png)

OPERATION

WARNING: To reduce the risk of fire, explosion, or damage to Vac:

- Do not leave Vac running while unattended - you may fail to notice important signs indicating abnormal operation such as loss of suction, debris/liquid exiting the exhaust, or abnormal motor noises. Immediately stop using Vac if you notice these signs.

- Do not leave Vac plugged in when not in use.

- Do not continue running when float has cut off suction.

- Sparks inside the motor can ignite airborne flammables. Do not operate Vac near flammable liquids or in areas with flammable gases, vapors, or explosive airborne dust. Flammable liquids, gases, and vapors include: lighter fluid, solvent-type cleaners, oil-based paints, gasoline, alcohol, and aerosol sprays. Explosive dusts include: coal, magnesium, aluminum, grain, and gun powder.

- Do not vacuum up explosive dusts, flammable liquids, or hot ashes.

- Do not leave sawdust or rags with stain or polyurethane residue inside Vac. Empty drum after picking up these potentially self-heating materials.

WARNING: To reduce the risk of electric shock or injury:

- Do not expose to rain or allow liquid to enter motor compartment. Store indoors.

- Do not handle plug, switch, or Vac with wet hands.

- Unplug Vac before servicing. If your Vac is not working as it should, has missing parts, has been dropped, damaged, left outdoors, or dropped into water, call customer service at 1-888-331-4569 (Mexico 001-881-331-4569).

- When using an extension cord, use only outdoor-rated cords that are in good condition. Do not allow the connection to come into contact with liquid.

CAUTION: To reduce the risk of hearing damage, wear ear protectors when using the Vac / Blower for extended time or in a noisy area.

Polarized Plug

To reduce the risk of electric shock, this Vac has a Polarized Plug (one blade is wider than the other). This Plug will fit in a Polarized Outlet only one way. If the Plug does not fit fully in the Outlet, reverse the Plug. If it still does not fit, contact a qualified electrician to install the proper Outlet. Do not change the Plug in any way.

After you Plug the Power Cord into the Outlet, turn the Unit on by pushing the Switch from position “O” to position “l”. The symbols used on the Switch Actuator are International “On & Off” Symbols:

-684397.png)

Vacuuming Dry Materials

- The Filter must always be in correct position to reduce the risk of leaks and possible damage to Vac.

- When using your Vac to pick up very fine dust, it will be necessary for you to empty the Drum and clean the Filter at more frequent intervals to maintain peak Vac performance.

NOTE: A dry Filter is necessary to pick up dry material. If you use your Vac to pick up dust when the Filter is wet, the Filter will clog quickly and be very difficult to clean.

Vacuuming Liquids

WARNING: Do not operate without filter cage and float, as they prevent liquid from entering the impeller and damaging the motor. For dry material pick-up, do not operate without the filter in place to reduce the risk of damage to the motor.

WARNING: To reduce the risk of fire or explosion, do not vacuum flammable or combustible liquids, gases or dust.

- When picking up small amounts of liquid the Filter may be left in place.

- When picking up large amounts of liquid we recommend that the Filter be removed. If the Filter is not removed, it will become saturated and misting may appear in the exhaust.

- After using the Vac to pick up liquids, the Filter must be dried to reduce the risk of possible mildew and damage to the Filter.

- When the liquid in the Drum reaches a predetermined level, the Float mechanism will rise automatically to cut off air-flow. When this happens, turn off the Vac, unplug the Power Cord, and empty the Drum. You will know that the Float has risen because Vac airflow ceases and the Motor noise will become higher in pitch, due to increased Motor Speed.

IMPORTANT: To reduce the risk of damage to the Vac do not run Motor with Float in raised position.

When using an extension cord, use only outdoor-rated cords that are in good condition. Do not allow the connection to come into contact with liquid.

Emptying the Drum (Fig. I)

- Remove the Powerhead Assembly. Pull Latches to release from the Drum.

- Lift the Powerhead Assembly up and away from the Drum.

- Lay Powerhead Assembly upside down on a clean area while emptying the Drum.

- Dump the Drum contents into the proper waste disposal container.

- If the Vac comes equipped with a Drain, simply unscrew the Drain Cap and lift the opposite side slightly to empty the Drum.

WARNING:

To reduce the risk of back injury or falls, do not lift a Vac heavy with liquid or debris. Scoop or drain enough contents out to make the Vac light enough to lift comfortably.

-731793.png)

Moving the Wet/Dry Vac (Fig. J)

Should it become necessary to pick the Vac up to move it, use the Dust Drum Latch Handles.

To maneuver the Vac, the Carry Handle on top of the Powerhead Assembly should be used.

-414150.png)

Muffler / Diffuser (Fig. K)

Depending on your Model, your Vac may come with a Muffler/Diffuser. Insert the Muffler/Diffuser Locking End into the Vac Blowing Port, when the Vac is not being used as a Blower. The Muffler/Diffuse should snap into place.

To Remove the Muffler/Diffuser from the Blowing Port, press the Muffler/Diffuser Release Button and pull out of the Blowing Port.

-344494.png)

Blowing Feature (Fig. L)

Your Vac features a Blowing Port. It can blow sawdust and other debris. Follow the following steps to use your Vac as a Blower.

- Locate Blowing Port of your Vac.

- Insert the Locking End of the Hose Assembly into the Vac Blowing Port. The Hose should snap into place. To Remove the Hose from the Vac, press the Release Button in the Hose Assembly and pull the Hose out of the Vac Blowing Port.

- Optional) Attach the Extension Wand to opposite end of Hose, then place the Car Nozzle on the Wand.

- Turn Vac on and you are ready to use your Vac as a Blower.

-923788.png)

MAINTENANCE

Filter

WARNING: To reduce the risk of injury from accidental starting, unplug power cord before changing or cleaning filter

NOTE: This Filter is made of high quality paper designed to stop very small particles of dust. The Filter can be used for wet or dry pick up. Handle the Filter carefully when removing to install or clean. Creases in the Filter pleats may occur from installation but creases will not affect the performance of the Filter.

Removal and Installation of the Qwik Lock™ Filter (Fig. M)

IMPORTANT: To reduce the risk of damage to the Blower Wheel and Motor, always reinstall the Filter before using the Vac for dry material pickup.

Filter Removal

- Hold the Filter Tabs of the Qwik Lock™ Filter in each hand.

- With one thumb on the Qwik Lock™ Stud, which protrudes through the integrated Filter Plate, lift up on the Filter Tabs while pushing down on the Stud.

- This action will cause the Filter to release from the Filter Cage. Slide Filter off Cage.

WARNING: Do not operate without a filter cage and float, as they prevent liquid from entering the impeller and damaging the motor

Filter Installation

- Carefully slide the Qwik Lock™ Filter over the Filter Cage and press down on the outside edge of the Filter until the Rubber Gasket on the bottom of the Filter seats securely around the base of the Filter Cage and against the Powerhead Assembly.

- Align the small Center Hole in the top of the Filter over the Qwik Lock™ Stud on the Filter Cage. Press firmly on top of the Filter near the Stud to allow the Filter to snap over the Ball on the end of the Stud. The Filter is now attached.

-822935.png)

NOTE: Failure to properly seat the bottom Gasket could result in debris bypassing the Filter.

Filter Bag

WARNING: To avoid health hazards from vapors or dust, do not vacuum toxic, carcinogenic or other hazardous materials such as asbestos, arsenic, barium, beryllium, lead, pesticides or other health endangering materials.

CAUTION: To avoid spilled debris, when picking up heavy or sharp material, monitor bag volume and do not overfill.

Filter Bag Installation (Fig. N)

A Filter Bag may be used in place of or in addition to the Qwik Lock™ Cartridge Filter.

Replacement Filter Bags are available:

NOTE: See Repair Parts List for Part Number.

NOTE: When picking up dry debris a Filter Bag or Cartridge Filter must be properly installed.

- Filter Bag to be used to pick up dry debris only.

- Correct positioning of Cardboard Collar is required to assure proper seal.

- Locate two Ribs on Inlet Tube, inside Drum.

- Slide Cardboard Collar onto Inlet Tube and position Cardboard Collar between the two Ribs.

- With the Cardboard Collar securely installed, unfold and position Filter Bag inside Drum, as shown.

-843554.png)

Filter Bag Removal (Fig. O)

- Slide Cardboard Collar toward center of Vac Drum.

- Remove Filter Bag from Vac Drum and discard.

- Install new Filter Bag.

-274598.png)

Filter Cleaning

Your Filter should be cleaned often to maintain peak Vac performance.

Cleaning A Dry Filter

- Some removal of dry debris can be accomplished without removing the Filter from the Vac. Slap your hand on top of the Powerhead Assembly while the Vac is turned off.

- For best cleaning results due to accumulated dust, clean the Filter in an open area. Cleaning SHOULD be done outdoors and not in the living quarters.

- After Filter removal from Vac, remove the dry debris by gently tapping Filter against the inside wall of your Dust Drum. The debris will loosen and fall.

- For thorough cleaning of dry Filter with fine dust (no debris), run water through it as described under\ “Cleaning A Wet Filter”.

Cleaning A Wet Filter

After Filter is removed, run water through the Filter from a hose or spigot. Take care that water pressure from the hose is not strong enough to damage Filter.

IMPORTANT: After cleaning, check the Filter for tears or small holes. Tears and holes in the Filter can cause debris and dust to be blown from the Vac. Do not use a Filter with holes or tears. Replace immediately.

Allow the Filter to dry before reinstalling and storing the Vac or picking up dry debris.

Cleaning and Disinfecting the Wet/Dry Vac

To keep your Wet/Dry Vac looking its best, clean the outside with a cloth dampened with warm water and mild soap.

To clean the Drum:

- Dump debris out.

- Wash Drum thoroughly with warm water and mild soap.

- Wipe out with dry cloth.

Before prolonged storage or as needed (i.e., waste water pick up) the Drum should be disinfected.

To disinfect the Drum:

- Pour 1 gallon (4 L) of water and 1 teaspoon (5 mL) chlorine bleach into the Drum.

- Let solution stand for 20 minutes, carefully swishing every few minutes, making sure to wet all inside surfaces of the Drum.

- Empty Drum after 20 minutes. Rinse with water until bleach smell is gone. Allow Drum to dry completely before sealing the Motor on the Drum.

Casters

If your Casters are noisy, you may put a drop of oil on the Roller Shaft to make them quieter.

Storage

Before storing your Vac, the Drum should be emptied and cleaned. The Power Cord should be wrapped around the Carry Handle and the Hose should be stored as described in this manual. Accessories should be kept in the same area as the Vac so they can be readily available. The Vac should be stored indoors.

WARNING: SERVICING OF DOUBLE-INSULATED WET/DRY VAC

In a double-insulated Wet/Dry Vac, two systems of insulation are provided instead of grounding. No grounding means is provided on a double-insulated appliance, nor should a means for grounding be added. Servicing a double-insulated Wet/Dry Vac requires extreme care and knowledge of the system, and should be done only by qualified service personnel. Replacement parts for a double-insulated Wet/Dry Vac must be identical to the parts they replace. Your double-insulated Wet/Dry Vac is marked with the words “DOUBLE INSULATED” and the symbol -224020.png) (square within a square) may also be marked on the appliance.

(square within a square) may also be marked on the appliance.

To reduce the risk of injury, unplug power cord before servicing the Wet/Dry Vac.

SERVICE / REPAIR PARTS

6 Gallon (22.5 Liter) Wet/Dry Vac

Model Number: CMXEVBE175840

Electrical Rating: 120 V~ 7.5 A 60 Hz

9 Gallon (34 Liter) Wet/Dry Vac

Model Number: CMXEVBE175900

Electrical Rating: 120 V~ 8.3 A 60 Hz

12 Gallon (45 Liter) Wet/Dry Vac

Model Number: CMXEVBE175940

Electrical Rating: 120 V~ 10.5 A 60 Hz

16 Gallon (60 Liter) Wet/Dry Vac

Model Number: CMXEVBE175950

Electrical Rating: 120 V~ 12 A 60 Hz

20 Gallon (75 Liter) Wet/Dry Vac

Model Number: CMXEVBE175960

Electrical Rating: 120 V~ 12 A 60 Hz

-424437.png)

See other models: CMXEVBE17607 17612 CMEW320 CMXEVBE17595 CMCE520B