Loading ...

Loading ...

Loading ...

16

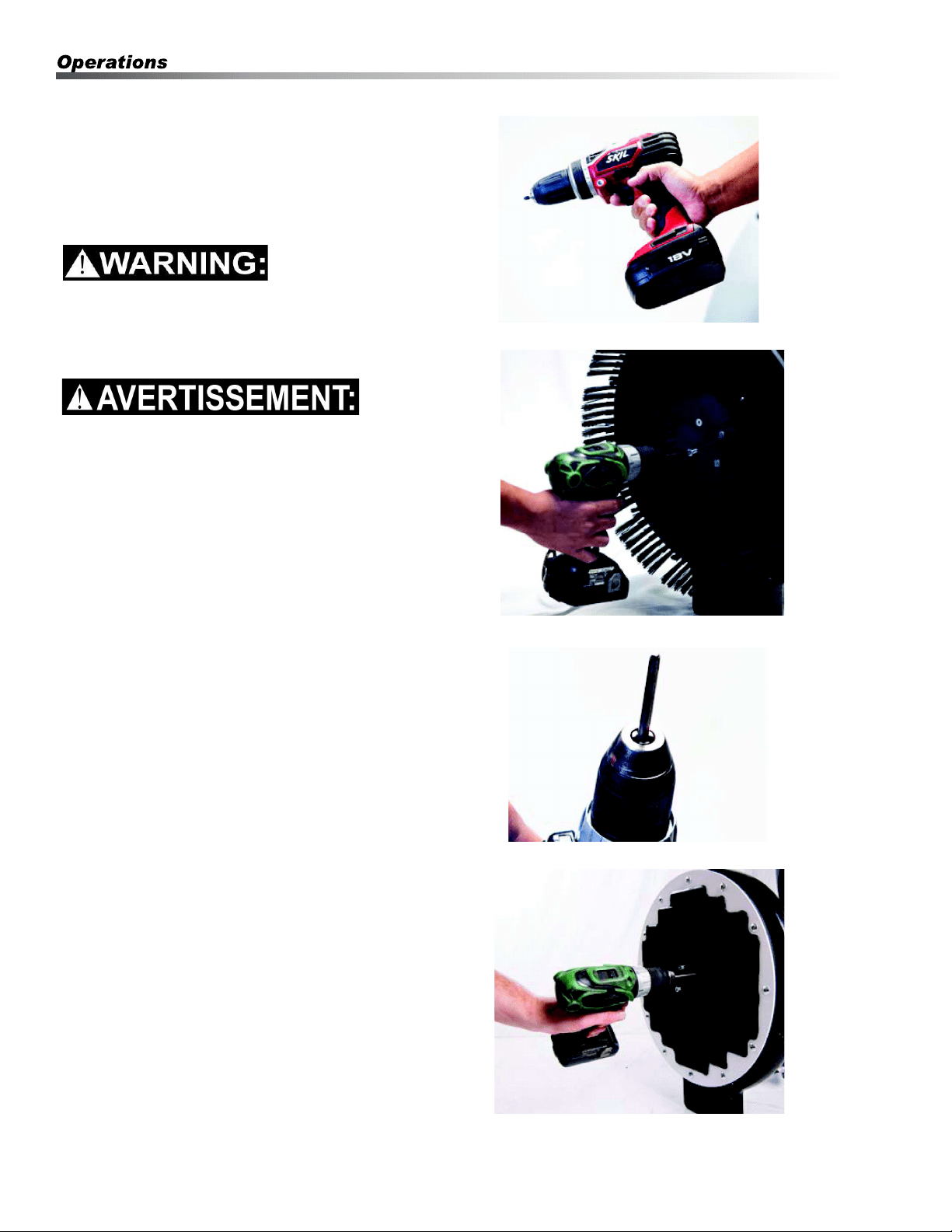

Brush Installation

Put the machine base in an upright position, sitting on

the foot of the bumper.

Remove the driver plate by removing the four counter-

sink screws in the center of the plate using an electric

screwdriver.

It is important to only use a Number 3 Phillips head

screwdriver bit. Smaller bit sizes can damage the

screw heads and leave sharp edges, which can tear

or snag the pads.

Il est important de n'utiliser qu'un embout de

tournevis Phillips numéro 3. Des embouts de

tailles inférieures peuvent endommager les têtes

de vis et laisser des arêtes vives, qui peuvent se

déchirer ou accrocher les tampons.

Damaged screws can cause further damage.

Mount the brush with the same countersink screws

used for mounting the driver plates.

NOTE: Tighten the screws sufficiently to avoid

disengagement of the brush from the machine during

operation

To avoid stripping the screws do not over tighten. An

electric screwdriver with a clutch will ensure that

stripping will not occur.

Attaching and Removing the Driver Plates

Put the machine base in an upright position, sitting on

the foot of the bumper. Remove the driver plate by

removing the four countersink screws in the center of

the plate using an electric screwdriver.

Attach a driver plate to the machine base by lining up

the holes of the driver plate with the appropriate

threads of the bearing retainer ring. It is recommended

to align the threads of the bearing horizontally to the

ground.

Put the four countersink screws through the holes of

the driver plate and first screw them into the bearing

retainer ring threads manually. Then, tighten the screws

with an electric screwdriver

8.638-856.0 Manual Operators - Radiant Orbital Scrubber

Loading ...

Loading ...

Loading ...