Loading ...

Loading ...

Loading ...

9

The following instructions are provided for qualified installers

so that they may accomplish installation, adjustment and

technical maintenance operations correctly and in

compliance with national current regulations and standards.

Important: the appliance should be disconnected from

the mains electricity supply before any adjustment,

maintenance, etc. is carried out. Maximum caution should

be exercised should it be necessary to keep the appliance

connected to the electricity supply.

The cookers have the following technical specifications:

Cat. II2H3+

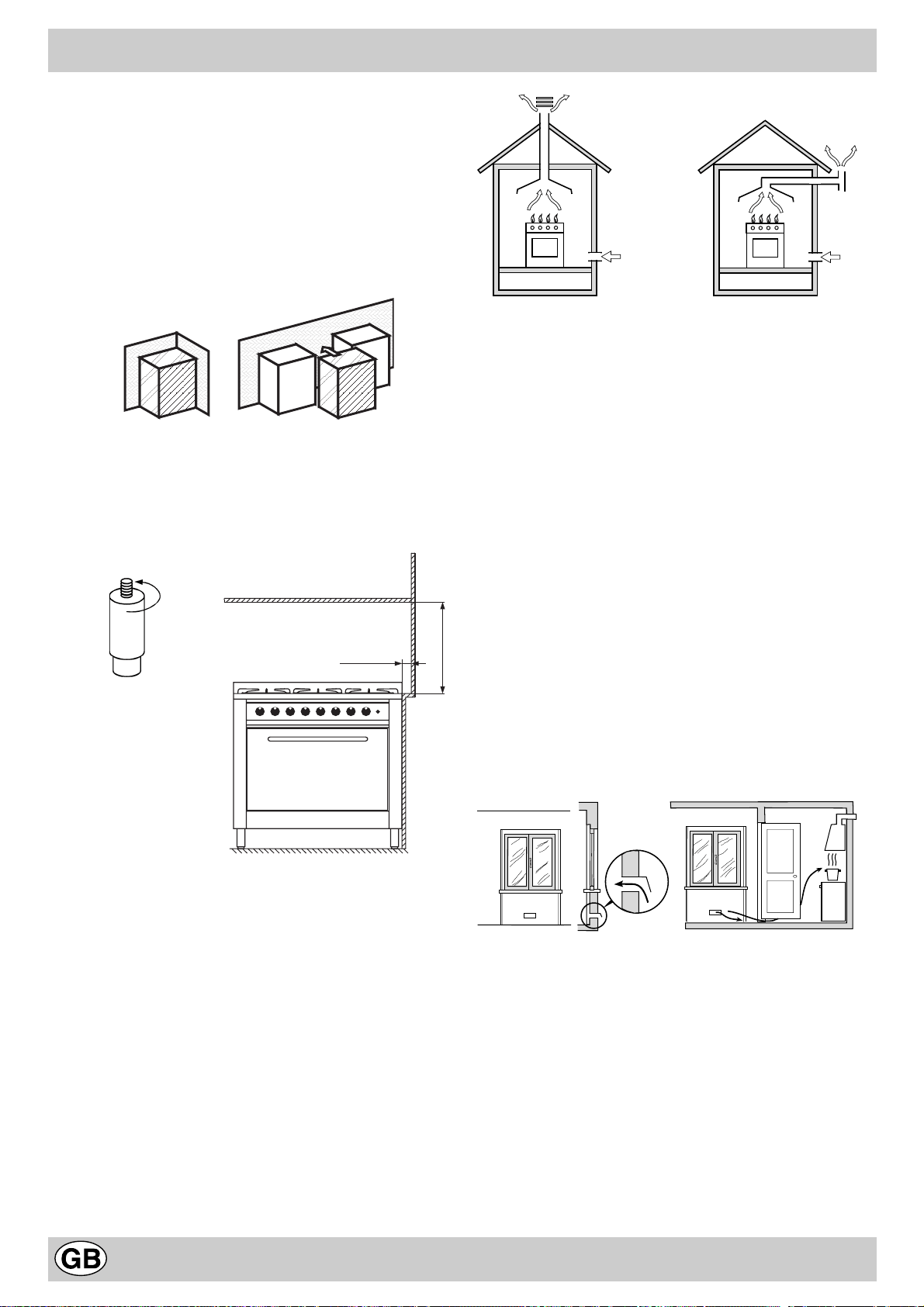

The maximum dimensions of the appliance are given in the

figure on page 2. For trouble-free operation of appliances

installed in housing units, the minimum distances shown in

fig.8 should be observed. Adjacent surfaces and the wall at

the rear should also be able to withstand a temperature of

65 °C

Prior to installing the cooker, 99 ÷ 155 mm high supporting

feet (provided) should be fitted into the holes to be found in

the bottom of the cooker (fig.9). These feet are screw-

adjustable and whenever necessary should be used to make

sure the cooker stands level.

Positioning

This appliance may only be installed and operated in

permanently ventilated rooms in compliance with provisions

laid down by current regulations and standards. The following

requirements must be observed:

• The appliance must discharge combustion products into a

special hood, which must be connected to a chimney, flue

pipe or directly to the outside (fig.10).

• If it is impossible to fit a hood, the use of an electric fan is

permitted, either installed on a window or on an external

wall, which must be switched on at the same time as the

appliance.

INSTRUCTIONS FOR THE INSTALLER

In a chimney stack or branched flue Directly to the outside

(exclusively for cooking appliances)

Kitchen ventilation

The air flow into the room where the appliance is installed

must be equal to the quantity of air that is required for regular

combustion of the gas and for ventilating the same room.

Air must be taken in naturally through permanent apertures

made in the outside walls of the room or through single or

branching collective ventilation ducts in compliance with the

standards in force. The air must be taken directly from the

outside, from an area far from sources of pollution. The

ventilation aperture must have the following characteristics

(fig.11A):

• total free cross section of passage of at least 6 cm² for

every kW of rated heating capacity of the appliance, with

a minimum of 100 cm² (the heating capacity is indicated

on the rating plate);

• it must be made in such a way that the aperture cannot be

obstructed both on the inside and outside of the wall;

• it must be protected, e.g. with grills, wire mesh, etc. in

such a way that the above-mentioned free section is not

reduced;

• it must be situated as near to floor level as possible.

Detail A Adjacent Room to be

room ventilated

A

Examples of ventilation holes Enlarging the ventilation slot

for comburant air between window and floor

fig. 11A fig.11B

The air inflow may also be obtained from an adjoining room,

provided the latter is not a bedroom or a room where there

is a risk of fire, such as warehouses, garages, fuel stores,

etc. and is ventilated in compliance with the standards in

force. Air from the adjoining room to the one to be ventilated

may be made to pass freely through permanent apertures

with a cross section at least equal to that indicated above.

These apertures may also be obtained by increasing the

gap between the door and the floor (fig.11B). If an electric

fan is used for extracting the combustion products, the

ventilation aperture must be increased in relation to its

maximum performance. The electric fan should have a

fig.9

fig.10

fig.8

min. 50mm

min. 700mm

Class 1 Class 2 sub-class 1

Loading ...

Loading ...

Loading ...