Loading ...

Loading ...

Loading ...

3M™ VHB™ Tape 5925

Handling/Application Information

Application Techniques

Clean: Most substrates are best prepared by cleaning with a 50:50 mixture of isopropyl alcohol (IPA*) and water prior to applying 3M™ VHB™ Tapes.

Exceptions to the general procedure that may require additional surface preparation include:

• Heavy Oils: A degreaser or solvent-based cleaner may be required to remove heavy oil or grease from a surface and should be followed by cleaning with IPA/water.

• Abrasion: Abrading a surface, followed by cleaning with IPA/water, can remove heavy dirt or oxidation and can increase surface area to improve adhesion.

• Adhesion Promoters: Priming a surface can signicantly improve initial and ultimate adhesion to many materials such as plastics and paints.

• Porous surfaces: Most porous and bered materials such as wood, particleboard, concrete, etc. need to be sealed to provide a unied surface.

• Unique Materials: Special surface preparation may be needed for glass and glass-like materials, copper and copper containing metals, and plastics or rubber that

contain components that migrate (e.g. plasticizers).

Refer to 3M Technical Bulletin “Surface Preparation for 3M™ VHB™ Tape Applications” for additional details and suggestions. (70-0704-8701-5)

*Note: These cleaner solutions contain greater than 250 g/l of volatile organic compounds (VOC). Please consult your local Air Quality Regulations to be sure the

cleaner is compliant. When using solvents, be sure to follow the manufacturer’s precautions and directions for use when handling such materials.

Pressure: Bond strength is dependent upon the amount of adhesive-to-surface contact developed. Firm application pressure develops better adhesive contact and

helps improve bond strength. Typically, good surface contact can be attained by applying enough pressure to insure that the tape experiences approximately 15 psi

(100 kPa) pressure. Either roller or platen pressure can be used. Note that rigid surfaces may require 2 or 3 times that much pressure to make the tape experience 15

psi.

Temperature: Ideal application temperature range is 70°F to 100°F (21°C to 38°C). Pressure sensitive adhesives use viscous ow to achieve substrate contact area.

Minimum suggested application temperature for the 3M™ VHB™ Tape 5952 family is 50°F (10°C). Minimum application temperature does vary by 3M™ VHB™ tape

family and ranges from 32°F to 60°F (0°C to 15°C)

Note: Initial tape application to surfaces at temperatures below these suggested minimums is not recommended because the adhesive becomes too rm to adhere

readily. However, once properly applied, low temperature holding is generally satisfactory. To obtain good performance with all 3M™ VHB™ Tapes, it is important to

ensure that the surfaces are dry and free of condensed moisture.

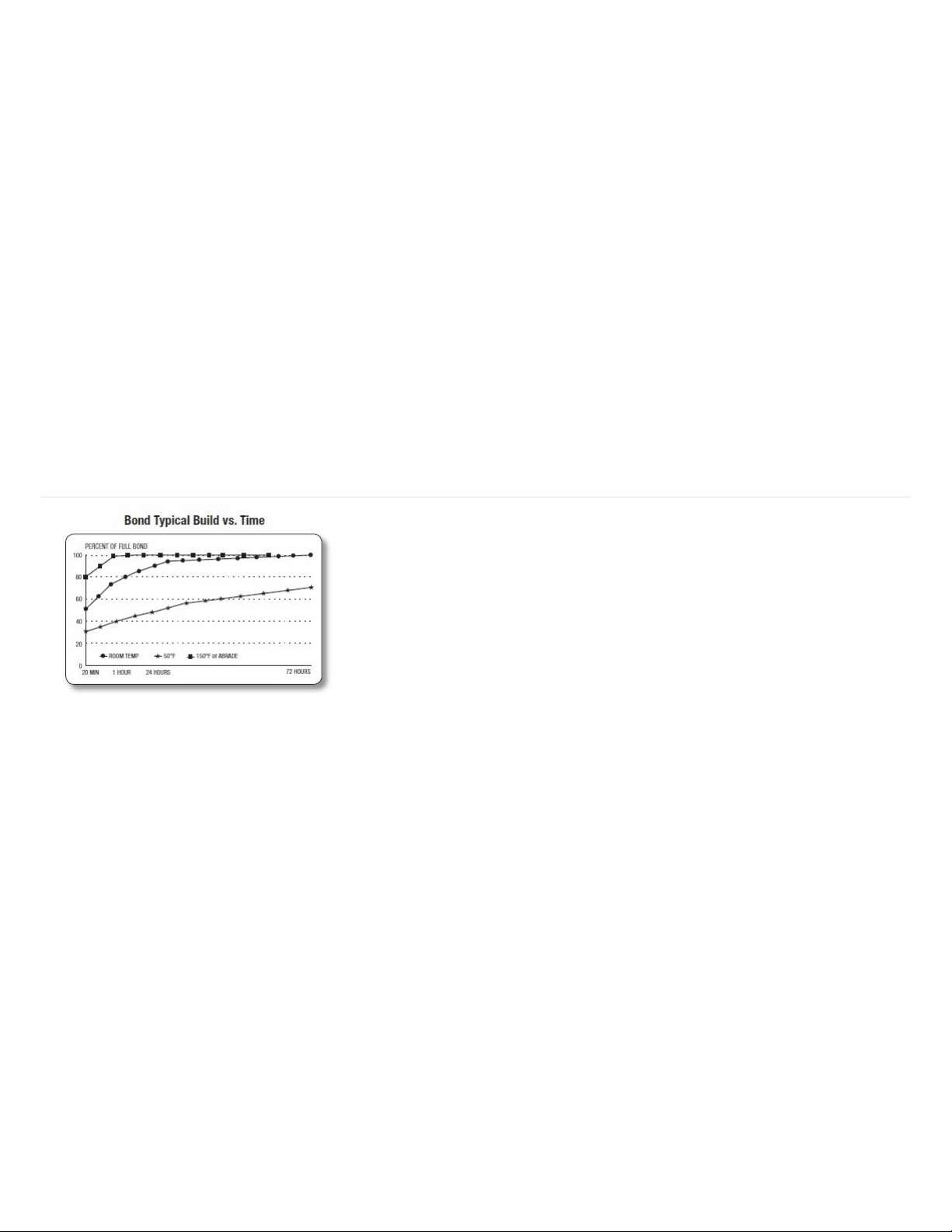

Time: After application, the bond strength will increase as the adhesive ows onto the surface (also referred to as “wet out”). At room temperature approximately 50%

of ultimate bond strength will be achieved after 20 minutes, 90% after 24 hours and 100% after 72 hours. This ow is faster at higher temperatures and slower at lower

temperatures. Ultimate bond strength can be achieved more quickly (and in some cases bond strength can be increased) by exposure of the bond to elevated

temperatures (e.g. 150°F [66°C] for 1 hour). This can provide better adhesive wetout onto the substrates. Abrasion of the surfaces or the use of primers/ adhesion

promoters can also have the eect of increasing bond strength and achieving ultimate bond strength more quickly.

Loading ...

Loading ...