Loading ...

3M™ VHB™ Tape 5925

Technical Information Note

The following technical information and data should be considered representative or typical only and should not be used for specication purposes.

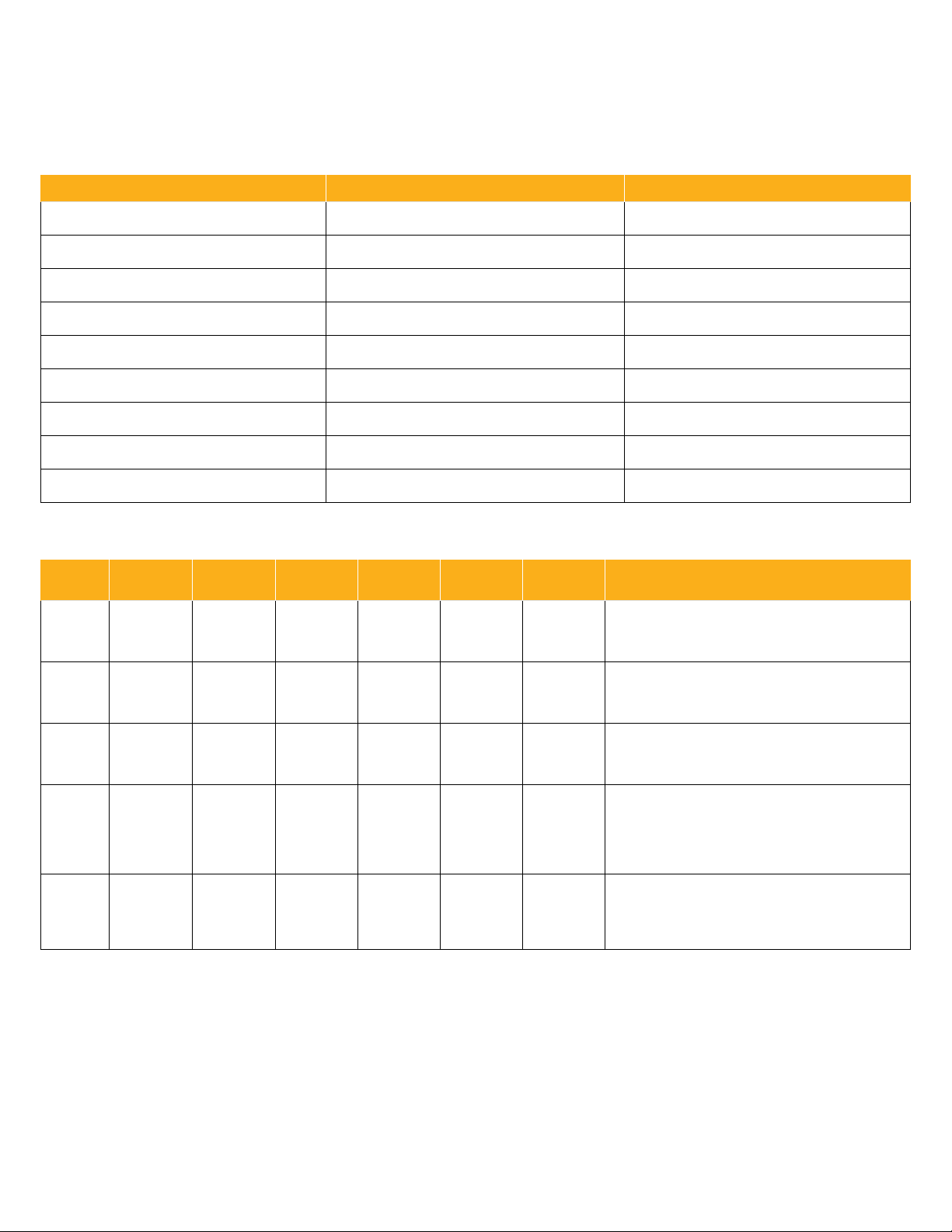

Typical Physical Properties

Property Values

Color Black

Tape Thickness 0.6 mm 0.025 in

Thickness Tolerance ±15 %

Adhesive Type Modied Acrylic

Foam Type Very Conformable Acrylic Foam

Density 590 kg/m³ 37 lb/ft³

Liner PE Film

Liner Thickness 0.13 mm 0.005 in

Liner Color Red (printed)

Typical Performance Characteristics

Property Values Method

Dwell/Cure

Time

Test

Condition Substrate Notes

90° Peel

Adhesion

30 N/cm 17 lb/in ASTM

D3330

72 hr @

Room

Temperature

Room

Temperature

Stainless

Steel

Jaw speed 12 in/min (304.8 mm/min). Average force to

remove is measured.

Normal

Tensile

515 kPa 75 lb/in² ASTM D897 72 hr @

Room

Temperature

Room

Temperature

Aluminum 1 in² (6.45 cm²), Jaw Speed 2 in/min (50.8 mm/min).

Peak force to separate is measured.

Dynamic

Overlap

Shear

620 kPa 90 lb/in² ASTM

D1002

72 hr @

Room

Temperature

Room

Temperature

Stainless

Steel

1 in² (6.45 cm²), Jaw speed 0.5 in/min (12.7 mm/min).

Peak force to separate is measured.

Short

Term

Temperature

Tolerance

149 °C 300 °F No change in room temperature dynamic shear

properties following 4 hours conditioning at indicated

temperature with 100 g/static load. (Represents

minutes, hours in a process type temperature

exposure).

Long

Term

Temperature

Tolerance

93 °C 200 °F Maximum temperature where tape supports at least

250 g load per 0.5 in² in static shear for 10,000

minutes. (Represents continuous exposure for days or

weeks).

Loading ...

Loading ...

Loading ...