Loading ...

PROFESSIONAL SCOPE MOUNTING KITS

USER INSTRUCTIONS

F

IREARM

A

CCURIZING

T

ORQUE

WRENCH

D

e

c

r

e

a

s

e

T

or

q

u

e

Increase Torque

= =

Instruction #1009310

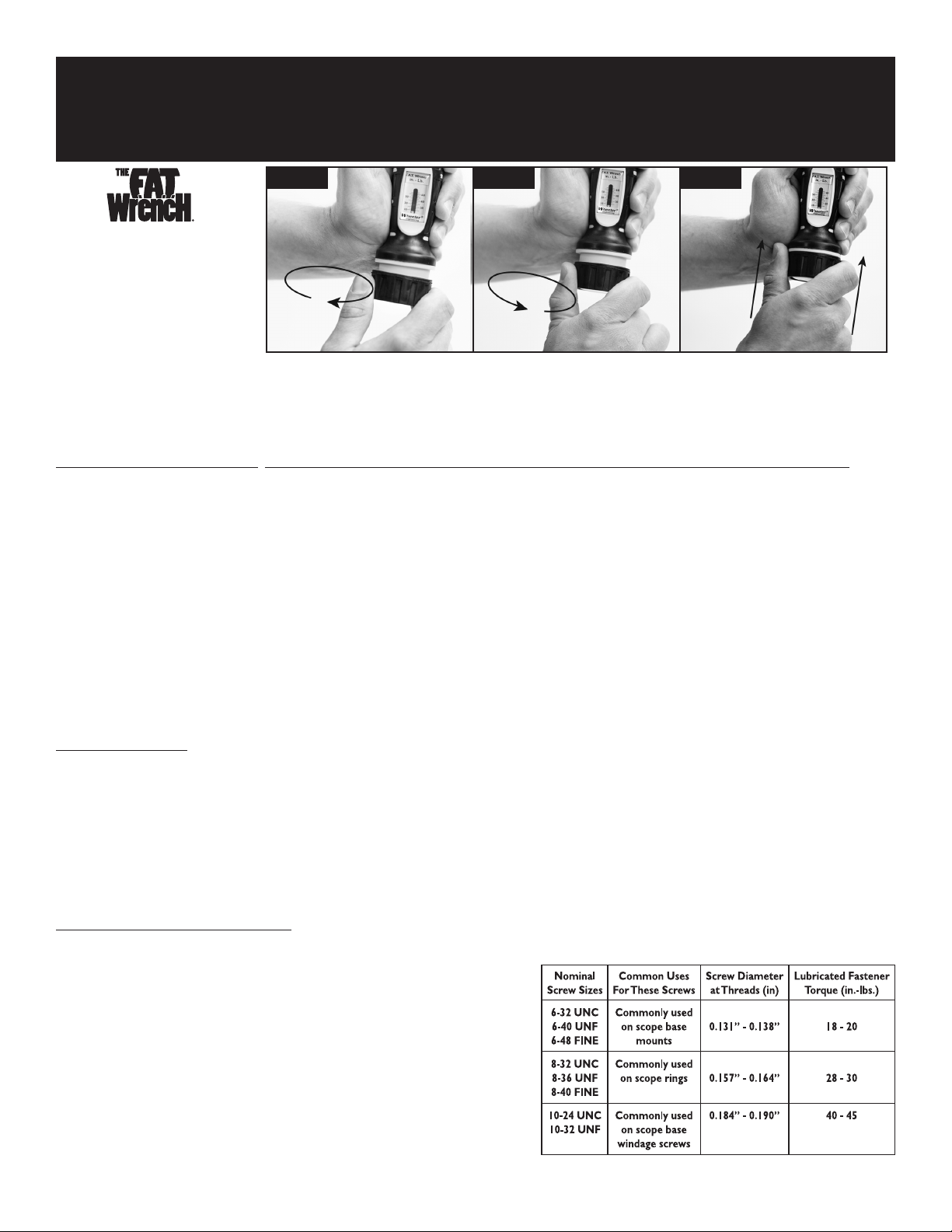

PHOTO 1 PHOTO 2 PHOTO 3

The Wheeler

®

Engineering F.A.T. Wrench

®

is a hand driven, click/clutch style torque wrench that is very useful for applying the

necessary torque to most rearm and rearm accessory fasteners. The F.A.T. Wrench

®

features a thick ergonomic handle, a

standard ¼” hex drive tip, and can be used to apply torque from 10 to 65 in-lbs at 5 in-lb increments. Common uses include, but

are not limited to; installation of scope ring and base screws, action screws and trigger guard screws. With proper care and use, the

F.A.T. Wrench

®

will provide you with a lifetime of reliable service. Package includes 9 bits and a square drive adapter.

TO ADJUST THE F.A.T. WRENCH

®

, PLEASE FOLLOW THESE STEPS TO GUARANTEE THE MOST ACCURATE TORQUE SETTINGS:

1. Begin with the F.A.T. Wrench

®

adjusted to the lowest torque setting. To do this, grasp the body of the F.A.T. Wrench

®

as shown in PHOTO 1. Using your other hand,

grasp the black knob at the bottom end of the handle. Pull the knob away from the handle to unlock it, and turn it counter-clockwise. The knob is spring loaded and

will return to the locked position when it is released, preventing it from being turned. You must repeatedly pull the knob and turn it counter-clockwise until it comes

to a stop. The red mark on the sliding indicator should be visible at the bottom of the scale below the 10 tic mark, as shown in PHOTO 1. This is also the where the

F.A.T. Wrench should be adjusted when it is not in use.

2. Using the same technique described in Step 1 to adjust the wrench, pull and turn the knob clockwise until the red mark on the sliding indicator is aligned with the

desired tic mark on the scale. This can be seen in PHOTO 2, where the F.A.T. Wrench

®

is adjusted to 30 in-lbs.

3. When the F.A.T. Wrench

®

is adjusted to the desired torque setting, make sure the knob has returned to the locked position. This may require turning the knob slightly

one way or the other and pressing it back into the locked position. See PHOTO 3.

4. Insert the bit needed into the hex drive tip. The F.A.T. Wrench

®

can now be used to apply torque to the fastener.

5. Tighten the fastener by turning the F.A.T. Wrench

®

clockwise. As the fastener begins to get tight, turn the F.A.T. Wrench

®

SLOWLY until you hear an audible click. Turn

it two more for a total of 3 clicks. The fastener has now been tightened with the torque specied on scale.

6. After use, return the F.A.T. Wrench

®

to the lowest torque setting as described in Step 1.

Note: When using the F.A.T. Wrench

®

to torque small fasteners, make sure the bit and the head of the fastener are correctly aligned. Correct alignment

will prevent damage to both the bit and fastener.

A FEW USEFUL TIPS:

• The F.A.T. Wrench

®

is used like a screwdriver; it is not a ratcheting device.

• Never leave the F.A.T. Wrench

®

adjusted at high torque settings for extended periods of time. Doing so will damage the internal mechanism, resulting in inaccurate

torque adjustment. ALWAYS ADJUST THE F.A.T. WRENCH

®

TO THE LOWEST TORQUE SETTING AFTER USE.

• Never adjust the F.A.T. Wrench

®

beyond a torque setting of 65 in-lbs. Doing so will damage the internal mechanism, resulting in inaccurate torque adjustment.

• The F.A.T. Wrench

®

is compatible with all of the bits contained in the Wheeler Engineering 89 Piece Screwdriver Set.

• The F.A.T. Wrench

®

was designed for +/- 2 in-lbs accuracy up to 40 in-lbs, +/- 5% over 40 in-lbs.

• The F.A.T. Wrench

®

can be used to apply torque to any fasteners; it is not limited to rearms and rearm accessories.

• Small, inexpensive screws can be damaged with high torque settings. Be sure to comply with recommended settings.

• Small bits can also be easily damaged with high torque settings. Replacement bits are available from many of our dealers and through our website.

RECOMMENDED TORQUE SETTINGS:

ALWAYS follow torque specications provided by scope base or ring manufacturer.

F.A.T. Wrench

®

Torque Range is 5 to 65 inch-pounds

Before applying torque to any fastener, consider whether the fastener is lubricated or dry/

degreased. Lubricated fasteners require much less torque to achieve consistent clamping power

compared to dry un-lubricated fasteners. Keep in mind that most fasteners used for installing

gun accessories are coated with oil to prevent corrosion. This oil as well as removable thread-

locking compounds that are often applied to screw threads should be considered as lubricant.

NOTE: The values tabulated below are for high grade (SAE Grade 8 or equivalent)

steel fasteners. If you are unsure about the size or quality of the fastener you

are installing, start with a lower torque value and only increase to the maximum

torques listed if you feel comfortable doing so. Bits are considered “use” items and

are not warrantied against bending or breakage.

The Wheeler Professional Scope Mounting Kits include everything you will need to properly mount a scope. An

instructional video outlining step by step instructions can found Online at www.btibrands.com/wheeler-smk-video/

These printed instructions can be referenced for additional detail on each of the key components of the kit.

Loading ...

Loading ...