Loading ...

Loading ...

Loading ...

14 | English

1 609 92A 1PC | (10.6.16) Bosch Power Tools

Selecting the Sanding Sheet

Select a sanding sheet with the appropriate grain as required for the desired surface removal rate. Bosch sanding sheets are suit-

able for paint, wood and metal.

Replacing the Sanding Sheet (see figures A–B)

To remove the sanding sheet 6, lift it from the side and pull it

off of the sanding plate 4.

When attaching a new sanding sheet, remove any dust or de-

bris from the sanding plate 4, e. g., with a brush.

The surface of the sanding plate 4 is fitted with Velcro backing

for quick and easy fastening of sanding sheets with Velcro ad-

hesion.

Press the sanding sheet 6 firmly against the bottom side of

the sanding plate 4.

To ensure optimum dust extraction, pay attention that the

punched holes in the sanding sheet match with the holes in

the sanding plate.

The alignment aid 7 can be used for alignment of the sanding

sheet 6 on the sanding plate 4. Place the sanding sheet with

the Velcro facing upward on the alignment aid. Press the cams

of the alignment aid into two holes of the sanding plate and

roll off the sanding sheet from the alignment aid. Press the

sanding sheet firmly against the sanding plate.

Selection of the Sanding Plate

Depending on the application, the machine can be equipped

with sanding plates of different hardness:

– Sanding plate, medium (black): Suitable for all sanding

work; universally usable.

– Sanding plate, soft (grey, accessory): Suitable for interme-

diate and fine sanding, incl. on convex surfaces.

Replacing the Sanding Plate (see figures C–D)

Note: Replace a damaged sanding plate 4 immediately.

Pull off the sanding sheet or the polishing accessory. Unscrew

the four screws 8 completely and remove the sanding plate 4.

Clean the upper side of the new sanding plate 4. Apply a thin

coat of synthetic grease to the outer ring hatched grey in the

figure.

Attach the new sanding plate 4 and tighten the four screws

again.

Note: A damaged sanding-plate base 9 may be changed only

by an authorised after-sales service agent for Bosch power

tools.

Dust/Chip Extraction

Dusts from materials such as lead-containing coatings,

some wood types, minerals and metal can be harmful to

one’s health. Touching or breathing-in the dusts can cause

allergic reactions and/or lead to respiratory infections of

the user or bystanders.

Certain dusts, such as oak or beech dust, are considered

as carcinogenic, especially in connection with wood-treat-

ment additives (chromate, wood preservative). Materials

containing asbestos may only be worked by specialists.

– As far as possible, use a dust extraction system suitable

for the material.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the mate-

rials to be worked.

Prevent dust accumulation at the workplace. Dusts can

easily ignite.

Integrated Dust Extraction with Dust Box

(see figures E–H)

Attach the dust box 3 onto the extraction outlet 10 until it

latches.

The filling level of the dust box 3 can easily be checked

through the transparent container.

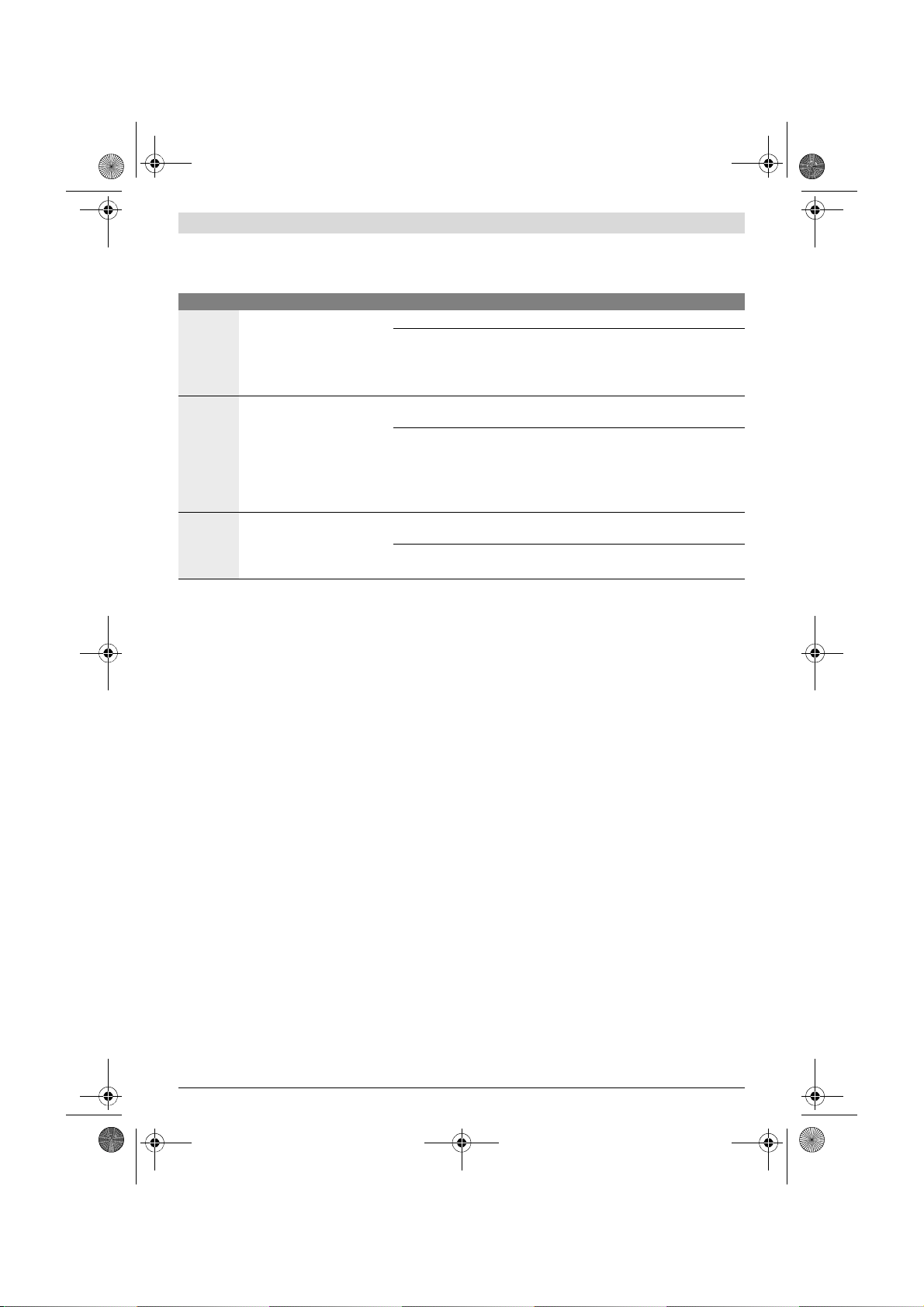

Operational area Application Grain size

Removal

(coarse sanding)

– Coarse sanding down with high

material removal

– Removal of old paint

– Sanding old paint, varnish and filler extra coarse 40

– Removal of thin coats

– Pre-sanding rough, unplaned surfaces

coarse 60

Preparation

(intermediate sanding)

– Light sanding down

– Light sanding of surfaces for

continued processing

– Face sanding and planing of irregularities

– Removing score marks from coarse-sanding

medium 80

– Evening out/touching up before applying

paint/varnish

fine 120

Fine Sanding

– Intermediate varnish sanding

– Light sanding of coating de-

fects

– Removal of fibres from surfaces

– Fine sanding before staining or glazing

very fine 180

– Light sanding of primer prior to coating extra fine 240

OBJ_BUCH-1334-005.book Page 14 Friday, June 10, 2016 11:42 AM

Loading ...

Loading ...

Loading ...