Loading ...

Loading ...

Loading ...

InstallationInstallation

Location Requirements

Gas requirements

Use only natural or LP (liquid propane) gases.

THE INSTALLATION MUST CONFORM WITH LOCAL CODES, OR IN THE ABSENCE

OF LOCAL CODES, WITH THE NATIONAL FUEL GAS CODE, ANSI Z223.1/NFPA 54,

LATEST REVISION (FOR THE UNITED STATES), OR THE NATURAL GAS AND PRO-

-PANE INSTALLATION CODE, CSA B149.1, (FOR CANADA).LATEST REVISION

Gas dryers are equipped with a burner vent for use with natural gas. If you plan to use

your dryer with LP (liquid propane) gas, it must be converted for safe and proper

performance by a qualified service technician.

A ½" (1.27cm) gas supply line is recommended and must be reduced to connect to the

3/8" (1cm) gas line on your dryer. The National Fuel Gas Code requires that an

accessible, approved manual gas shut-off valve be installed with 6" of your dryer.

Gas dryers installed in residential garages must be raised 18" (46cm) above the

floor.

Additionally, a 1/8" (0.3cm) N.P.T. (National Pipe Thread) plugged tapping, accessible

for test gauge connection, must be installed immediately upstream of your dryer’s gas

supply connection.

Your dryer must be disconnected from the gas supply pipe system during any pressure

testing of the system.

This dryer must be connected to the gas supply piping with a listed flexible gas conn-

-ector that complies with the standard for connectors for gas appliances, ANSI Z21.24

or CSA 6.10.

DO NOT reuse old flexible metal gas lines. Flexible gas lines must be design certified by

the American Gas Association (CGA in Canada).

- Any pipe joint compound used must be resistant to the action of any liquefied petroleum

gas.

- As a courtesy, most local gas utilities will inspect a gas appliance installation.

GAS IGNITION - Your dryer uses an automatic ignition system to ignite the burner.

There is no constant burning pilot.

COMMONWEALTH OF MASSACHUSETTS INSTALLATION INSTRUCTIONS

Your dryer must be installed by a licensed plumber or gas fitter. A “T” handle manual gas

valve must be installed in the gas supply line to your dryer.

If a flexible gas connector is used to install your dryer, the connector may not be longer

than 3' (36", 91.5cm).

- Gas leaks may occur in your system, creating a dangerous situation.

- Gas leaks may not be detected by smell alone.

- Gas suppliers recommend that you purchase and install a UL-approved gas

detector.

- Install and use it in accordance with the manufacturer’s instructions.

WARNING

Electric models - U.S. only

Most dryers require a 120/240 volt, 60Hz AC approved electrical service. Some require

120/208 volt, 60Hz approved electrical service. The electric service requirements can

be found on the data label located behind the door. A 30-amperefuse or circuit breaker

on both sides of the line is required.

- If a power cord is used, the cord should be plugged into a 30-ampere receptacle.

- The power cord is NOT provided with U.S. electric model dryers.

Location Requirements

RISK OF ELECTRIC SHOCK:

When local codes allow, the electrical supply of the dryer may be connected by

means of a new power supply cord kit, marked for use with a dryer, that is UL listed

and rated at a minimum of 120/240 volts, 30-ampere with three No. 10 copper wire

conductors terminated with closed loop terminals, open-end spade lugs with

turned up ends, or with tinned leads.

- Do not reuse a power supply cord from an old dryer. The power cord electric

supply wiring must be retained at the dryer cabinet with a suitable UL-listed

strain relief.

- Grounding through the neutral conductor is prohibited for (1) new branch-circuit

installations, (2) mobile homes, (3) recreational vehicles, and (4) areas where

local codes prohibit grounding through the neutral conductor. (Use a 4-prong

plug for 4 wire receptacles, NEMA type 14-30R.)

WARNING

Electric requirements

An individual branch (or separate) circuit serving only your dryer is recommended. DO

NOT USE AN EXTENSION CORD.

Gas models - U.S. and Canada

A 120Volt, 60Hz AC approved electrical service, with a 15 ampere fuse or circuit breaker

is required.

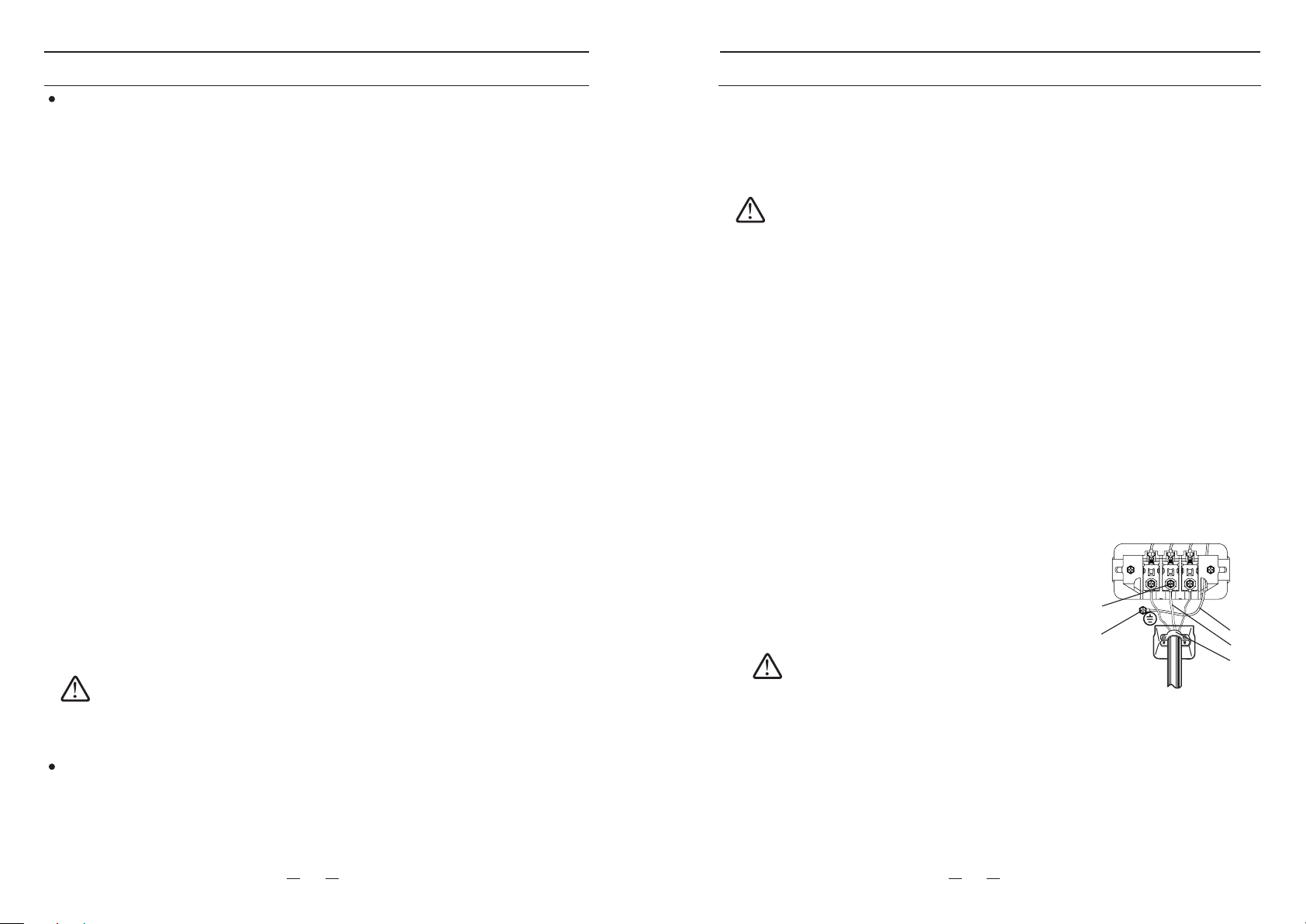

3-Wire system connections

1. Remove the center terminal block screw.

2. Connect the neutral wire (white or center wire) of the power cord to the center.

Cross the screw through the ring of the power cord terminal and tighten the screw.

3. Connect the other wires to the outer terminal block screws. Be sure to cross the

screw through the terminal ring and tighten the screw.

4. Remove the screws for the power cord fixing base. Cross the power cord to the

base, then install back and tighten the screws. Be sure to fix the power cord tightly.

5. Insert the tab of the terminal block cover into your dryer’s rear panel slot.

6. Secure the cover with a hold-down screw.

3-wire system instructions:

A.

external ground connector

C. Neutral grounding wire (White)

D. Neutral wire (white or center wire)

E. 3/4" (1.9cm) UL-listed strain relief

Center terminal block screw

B.

A

B

C

D

EIf converting from a 4-wire electrical system to a 3-wire,

the ground strap must be reconnected to the terminal block

support to ground the dryer frame to the neutral conductor.

WARNING

4-Wire system connections

1. Remove the center terminal block screw.

2. Connect the ground wire (green or unwrapped) of the power cord to the external

ground conductor screw.

3. Connect the neutral wire (white or center wire) of the power cord and the appliance

ground wire (white) under the center screw of the terminal block. Cross the screw

through the ring of wires’ terminal and tighten the screw.

4. Connect the other wires to the outer terminal block screws. Be sure to cross the

screw through the terminal ring and tighten the screw.

11

12

Loading ...

Loading ...

Loading ...