Loading ...

Loading ...

Loading ...

30

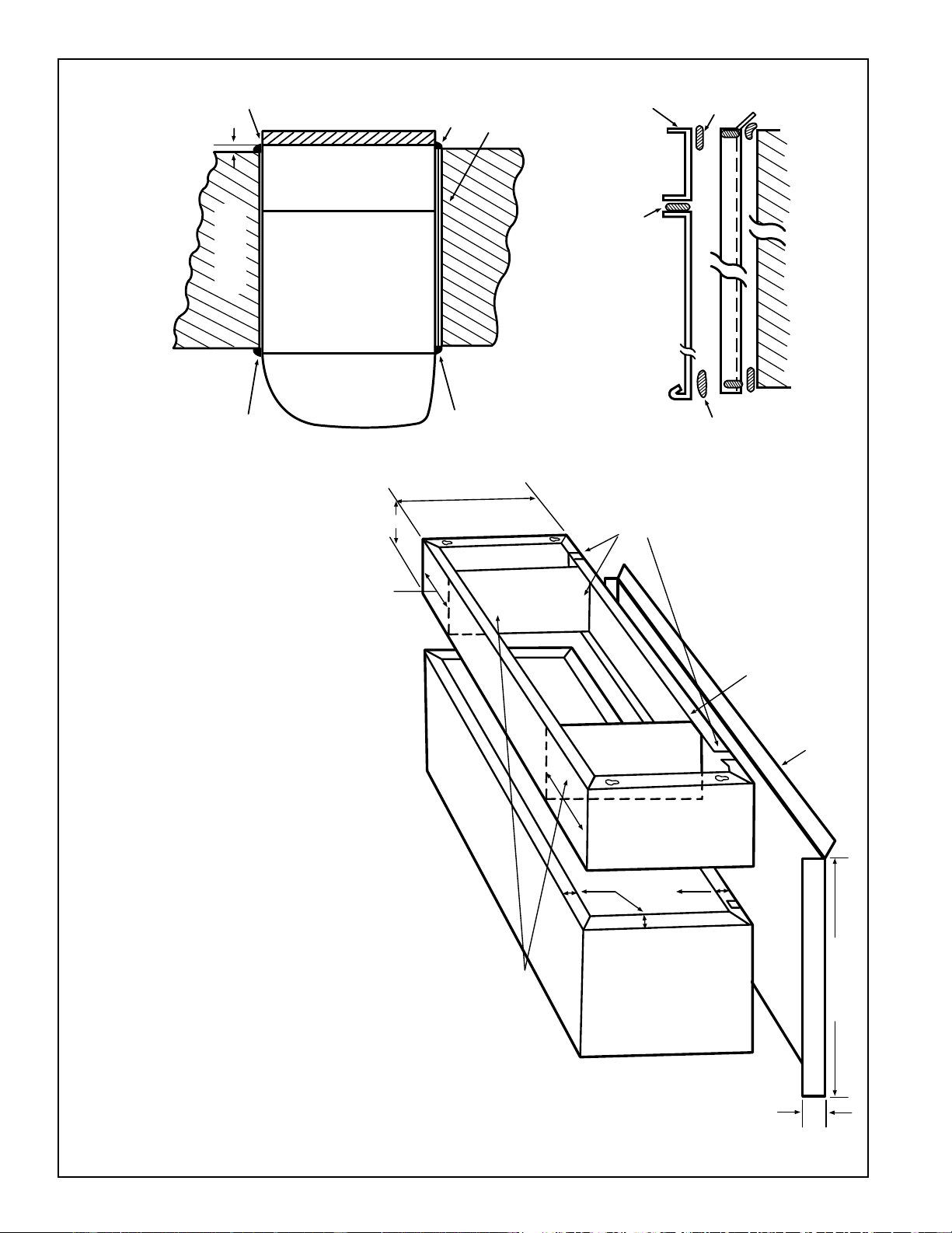

METAL CASE EXTENSION FOR WALLS DEEPER THAN 13-1/8" (11-1/8" WITH SUB-BASE)

FIELD FABRICATED – GE RECOMMENDS THE USE OF ONE OF THE DEEPER RAB71 WALL CASES OFFERED AS SPECIAL ORDER ITEMS. SEE PAGE 29.

CAULK*

SPLITTER BETWEEN

AIR INTAKE AND

DISCHARGE

Zoneline units can be installed in walls of greater

depth than the wall case. Where the case recession

is less than 3” and where it is possible to waterproof

the exposed sides and top of the opening, the

suggested procedure is to apply a flashing to the

bottom of the wall case as shown on page 29.

Where waterproofing is questionable or not

possible, or for installations in walls of greater

depth, the following is a suggested application

procedure. It involves the field fabrication of a case

extension. Since the wall case is a water bearing

container, the extension likewise must also be

water bearing and the connection between the two

must be watertight. The case extension must

contain splitters to prevent recirculation of the

outdoor air circuit.

1. The case extension is field fabricated. The

extension depth “D” should allow for a minimum

outdoor projection of 1/4”. This allows for room

cabinet clearance to the finished wall and ample

surfaces to apply sealant or caulking for a tight

weather seal between the completed wall

case/extension assembly and the wall opening. It

is recommended that the extension be painted

and corner and lap joints be additionally sealed

with a quality grade sealant.

2. The wall case and extension should be

connected prior to installation in the wall

opening. A quality grade sealant should be

applied to all four (4) butting flanges. Use bolts

and nuts or oversized self tapping screws

(driven from the wall case to the extension) to

attach the two assemblies. Clean all drain holes

of excess sealant. The assembly must be free

draining.

3. Install flashing, using a quality grade sealant

between the flashing and wall as shown in

section A-A below.

4. Install the wall case/extension assembly

following procedures described for a standard

installation. See diagrams below. The assembly

should be sealed or caulked to the wall around

all four sides both outdoors and indoors.

NOTE: The wall case/extension assembly should

be level.

5. Suggested materials for case extension and

flashing should be non-ferrous metals. Minimal

acceptable material: Galvanized G-90 painted.

SEALANT - ALL

FOUR (4) FLANGES

6-1/4" ± 1/4"

AS REQ'D.

CUT DRAIN SLOTS

IN BOTH FLANGES

(FOUR REQUIRED)

TO MATCH DRAIN

HOLES IN RAB71/77

FLANGES AND

DRAIN HOLE

LOCATIONS

SAME AS ON

WALL CASE

1" WIDE

45° DRIP LIP

FLASHING (FIELD SUPPLIED)

13-3/4" + D"

2" MIN.

D

10-5/8" ± 1/4"

CAULK*

CAULK*

CAULK*

WALL -

ANY

CONSTRUCTION

RAB71/77ROOM

CABINET

CASE

EXT.

SEE DETAIL

SECTION A-A

*Caulk around perimeter of wall case all four sides

where it joins the building - Interior and Exterior.

EXTENSION

ALL 4 FLANGES

WALL CASE

ALL 4

SIDES

WALL

FLASHING

ALL 4

SIDES

SECTION A-A

BASEPAN/FLANGE DESIGN

SHOWING SEALANT LOCATIONS.

1/4" MIN.

RAB71/77

WALL CASE

1-1/2"

(4 SIDES)

EXTENSION

(FIELD

SUPPLIED)

2020 Data Manual 2002 11/7/02 3:19 PM Page 30

Loading ...

Loading ...

Loading ...