Loading ...

Loading ...

Loading ...

Installation

38

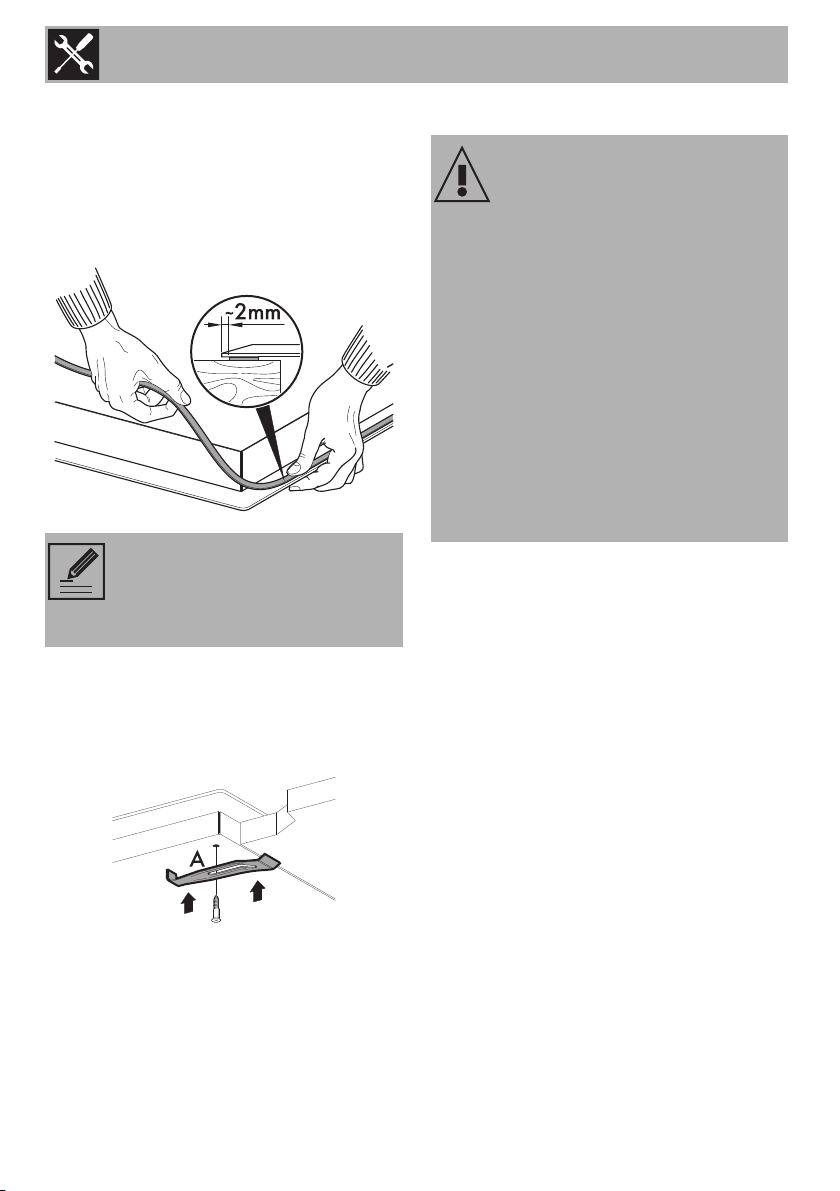

Hob seal

To prevent leakage of liquid between the

frame of the hob and the work surface,

place the adhesive seal provided along the

entire outer edge of the hob before

assembly.

5.4 Fixing brackets

Screw the fixing brackets (A) into the holes

on the sides of the bottom casing to

properly fasten the hob to the structure.

5.5 Gas connection

General information

Connection to the gas mains can be made

using a rigid copper pipe or a continuous

wall flexible steel hose in compliance with

the provisions established by the applicable

standard.

For supplying it with other types of gas, see

chapter “5.6 Adaptation to different types

of gas”. The gas inlet connection is

threaded ½” external gas (ISO 228-1).

Connection with a flexible steel hose

Make the connection to the gas mains

using a continuous wall flexible steel hose

whose specifications comply with the

applicable standard.

Do not use silicone to secure the

hob. This would make it impossible

to remove the hob, if necessary,

without damaging it.

Gas leak

Danger of explosion

• After carrying out any operation, check

that the tightening torque of gas

connections is between 10 Nm and 15

Nm.

• If required, use a pressure regulator that

complies with current regulations.

• At the end of the installation, check for

any leaks with a soapy solution, never

with a flame.

• The hoses should not come into contact

with moving parts and should not be

crushed in any way.

Loading ...

Loading ...

Loading ...