Loading ...

Loading ...

Loading ...

En-5

3-2. PIPE CONNECTION

1)Applyathincoatofrefrigerationoil(G)tothearedendsofthepipesandthe

pipe connections of the outdoor unit.

2) Align the center of the pipe with that of the pipe connections of the outdoor unit,

thenhandtightenthearenut3to4turns.

3)Tightenthearenutwithatorquewrenchasspeciedinthetable.

• Over-tightening maycause damage to the arenut, resultingin refrigerant

leakage.

• Besuretowrapinsulationaroundthepiping.Directcontactwiththebarepiping

may result in burns or frostbite.

3-3. INSULATION AND TAPING

1)Coverpipingjointswithpipecover.

2)Foroutdoorunitside,surelyinsulateeverypipingincludingvalves.

3) Using piping tape (E), apply taping starting from the entry of outdoor unit.

• Stoptheendofpipingtape(E)withtape(withadhesiveagentattached).

• Whenpipinghavetobearrangedthroughaboveceiling,closetorwherethe

temperature and humidity are high, wind additional commercially sold insulation

topreventcondensation.

WARNING

When installing the unit, securely

connect the refrigerant pipes before

starting the compressor.

CAUTION

When there are the ports which are

not used, make sure their nuts are

tightened securely.

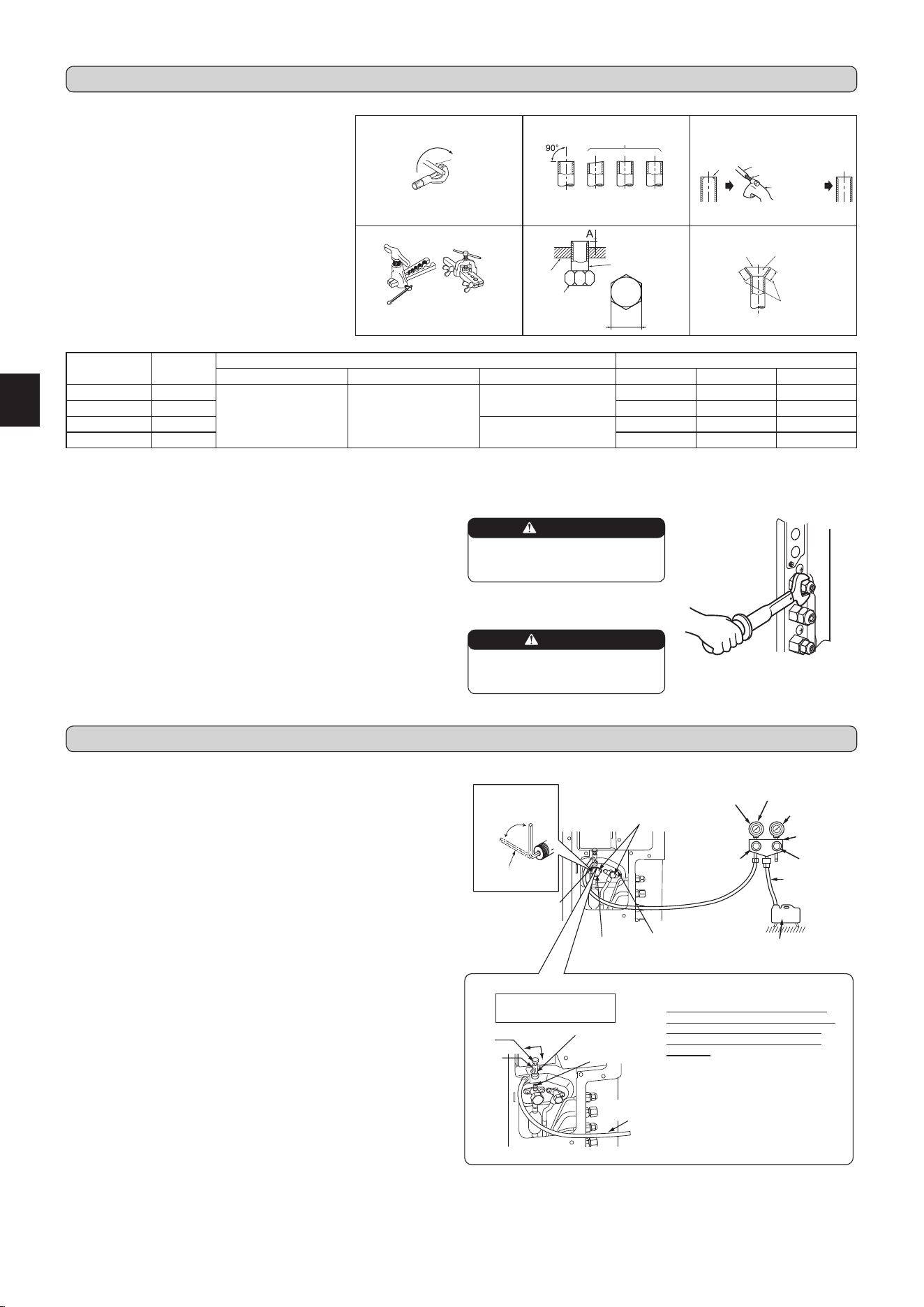

Fig. 1 Fig. 2 Fig. 3

Fig. 4 Fig. 5 Fig. 6

TiltedUnevenBurred

Good

No good

Burr

Copper pipe

Spare reamer

Pipe cutter

Smooth all

around

Evenlength

all around

Inside is shin-

ing without any

scratches.

B

Flare nut

Die

Copper pipe

Clutch type

Flaring tool

Wing nut type

Copper

pipe

Pipe diameter

[inch (mm)]

B

[inch (mm)]

A [inch (mm)] Tightening torque

Clutch type tool for R410A Clutch type tool for R22 Wing nut type tool for R22 ft-Ib N•m kgf•cm

1/4 (ø6.35) 21/32 (17)

0 to 0.02

(0 to 0.5)

0.04 to 0.06

(1.0 to 1.5)

0.06 to 0.08

(1.5 to 2.0)

10 to 13 13.7 to 17.7 140 to 180

3/8 (ø9.52) 7/8 (22) 25 to 30 34.3 to 41.2 350 to 420

1/2 (ø12.7) 1-1/32 (26)

0.08 to 1.0

(2.0 to 2.5)

36 to 42 49.0 to 56.4 500 to 575

5/8 (ø15.88) 1-5/32 (29) 54 to 58 73.5 to 78.4 750 to 800

3-1. FLARING WORK

1) Cut the copper pipe correctly with pipe cutter. (Fig. 1, 2)

2)Completelyremoveallburrsfromthecutcrosssectionof

pipe. (Fig. 3)

• Aimthecopperpipedownwardwhileremovingburrsto

preventburrsfromdroppinginthepipe.

3)Removearenutsattachedtoindoorandoutdoorunits,

thenputthemonpipehaving completedburrremoval.

(Notpossibletoputthemonafteraringwork.)

4)Flaringwork (Fig.4,5).Firmly holdcopperpipe in the

dimension shown in the table. Select A inch (mm) from

the table according to the tool selected.

5)Check

• ComparethearedworkwithFig.6.

• Ifareisnotedtobedefective,cutoffthearedsection

anddoaringworkagain.

4-1.PURGINGPROCEDURESANDLEAKTEST

1)Removeserviceportcapofstopvalveonthesideoftheoutdoorunitgaspipe.

(Thestopvalvesarefullyclosedandcoveredincapsintheirinitialstate.)

2)Connectgaugemanifoldvalveandvacuumpumptoserviceportofstopvalve

on the side of the outdoor unit gas pipe.

3)Runthevacuumpump.(Vacuumizeformorethan15minutes.)

4)Check thevacuum withgauge manifold valve,then closegauge manifold

valve,andstopthevacuumpump.

5)Leaveasitisforoneortwominutes.Makesurethepointerofgaugemanifold

valveremainsinthesameposition.Conrmthatpressuregaugeshows-14.7

psi[Gauge](-0.101MPa).

6)Removegaugemanifoldvalvequicklyfromserviceportofstopvalve.

7)Fullyopenallstopvalvesonthegaspipeandtheliquidpipe.Operatingwithout

fully opening lowers the performance and this causes trouble.

8)Referto1-2.,andchargetheprescribedamountofrefrigerantifneeded.Be

sure to charge slowly with liquid refrigerant. Otherwise, composition of the

refrigerant in the system may be changed and affect performance of the air

conditioner.

9)Tightencapofserviceporttoobtaintheinitialstatus.

10

)Leaktest

3. FLARING WORK AND PIPE CONNECTION

4. PURGINGPROCEDURES,LEAKTEST,ANDTESTRUN

Stopvalve

forGAS

Stopvalvecap

(Torque 19.6 to

29.4N•m,200

to300kgf•cm)

Gaugemanifold

valve(forR410A)

Compound pressure

gauge (for R410A)

–0.101MPa

(–760mmHg)

Handle

Low

HandleHigh

Vacuumpump

(for R410A)

*Close

*Open

Hexagonalwrench

*4 to 5 turns

Stopvalve

forLIQUID

Pressure gauge

(for R410A)

Precautions when us-

ingthecontrolvalve

Whenattachingthecontrolvalve

totheserviceport,valvecoremay

deform or loosen if excess pres-

sure is applied. This may cause

gasleak.

Serviceport

Charge hose

(for R410A)

Body

Close

Open

Control

valve

A

Whenattachingthecontrolvalveto

theserviceport,makesurethatthe

valvecoreisinclosedposition,and

then tighten part A. Do not tighten

partAorturnthebodywhenvalve

core is in open position.

Serviceportcap

(Torque 13.7 to

17.7N•m,140 to

180kgf•cm)

Charge hose

(for R410A)

BH79A325H03_en.indd 5 2018/08/06 13:12:25

Loading ...

Loading ...

Loading ...