Loading ...

Loading ...

Loading ...

18 Section 4 — Product care

Lubrication

DANGER

Bearing failures and overheating can result in fire/

Always follow the instructions in this manual regarding

lubrications locations and intervals. Contact your authorized

dealer with any questions about the lubrication locations

and intervals or any unusual noises coming from any areas a

bearing may be located.

WARNING

Before lubricating, repairing, or inspecting, always disengage

the PTO, set the parking brake, stop the engine and remove the

key to prevent unintended starting.

Front Wheels

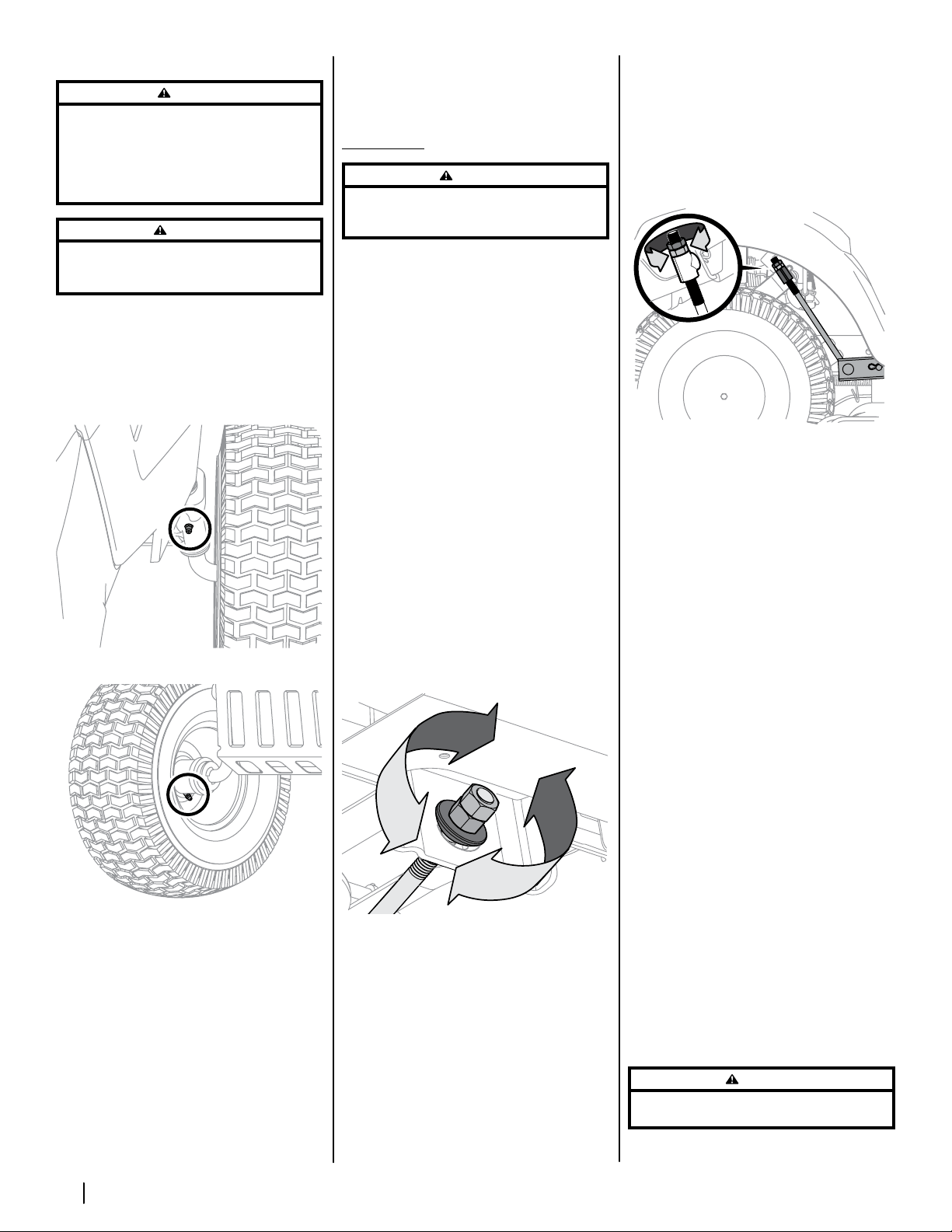

Each of the front wheel axles and rims is equipped

with a grease fitting. See Figure 4-2 for the location of

the grease fitting on the axles and Figure 4-3 for the

location of the grease fitting on the rims. Lubricate

with a No. 2 multi-purpose grease applied with a

grease gun after every 25 hours of tractor operation.

Figure 4-2

Figure 4-3

Deck Wheels

The wheels on the deck which are spherical shaped

(50” and 54” decks have 4) are equipped with a

grease fitting. Lubricate with a No. 2 multi-purpose

grease applied with a grease gun after every 25

hours of tractor operation.

Pivot Points & Linkage

Lubricate all the pivot points on the drive system,

parking brake and lift linkage at least once a

season with light oil.

Note: It is not necessary to grease the steering

pinion/sector gear interface. Doing so will allow dirt

to accumulate and can affect steering performance.

ydrostatic Transmission

The hydrostatic transmission is sealed at the factory

and is maintenance-free. The fluid level cannot be

checked and the fluid cannot be changed.

Adjustments

WARNING

Shut the engine off, remove the ignition key and engage

the parking brake before making adjustments. Protect your

hands by using heavy gloves when handling the blades.

Note : Check the tractor’s tire pressure before

performing any deck leveling adjustments. Refer

to Tires on page 11 for information regarding tire

pressure.

Adjusting the Deck

Leveling the Deck (Front-To-Rear)

The front of the deck is supported by a stabilizer

bar that can be adjusted to level the deck from

front to rear. The front of the deck should be

between ⁄” and ⁄” lower than the rear of the

deck. Adjust if necessary as follows:

1. Park the tractor on a firm, level surface and

place the deck lift lever in the middle position

and rotate the blade nearest the discharge

chute so that it is parallel with the tractor.

2. Measure the distance from the front of the blade

tip to the ground and the rear of the blade tip

to the ground. The front of the deck should be

between ⁄” and ⁄” less than the rear of deck.

3. Determine the approximate distance

necessary for proper adjustment and

proceed, if necessary.

4. To raise the front of the deck, loosen the

outer nut then tighten (thread inward) the nut

against the front hanger bracket. See Figure

4-4. When proper adjustment is achieved,

re-tighten the outer nut to 25-30 ft.-lbs.

Figure 4-4

5. To

lower the front of the deck, loosen the

outer nut then loosen (thread outward) the

nut, away from the front hanger bracket.

See Figure 4-4. When proper adjustment is

achieved, re-tighten the outer nut.

Leveling the Deck (Side-to-Side)

If the deck appears to be mowing unevenly, a

side-to-side adjustment can be performed. Adjust if

necessary as follows:

1. With the tractor parked on a firm, level

surface, place the deck lift lever in the

middle position and rotate both blades so

that they are perpendicular with the tractor.

2. Measure the distance from the outside of

the left blade tip to the ground and the

distance from the outside of the right blade

tip to the ground. Both measurements taken

should be equal. If they’re not, proceed to

the next step.

3. Under the rear fenders inside the wheels

there is a lift adjustment rod for each side of

the deck. See Figure 4-5.

Figure 4-5

4. Minor side-to-side adjustments should be

made using primarily the left adjustment rod.

5. To raise the left side of the deck, loosen the

upper nut on the end of the lift rod, then

turn the lower nut clockwise. When the

proper adjustment is achieved, tighten the

upper nut to secure in place. To lower the

left side of the deck, loosen the upper nut

on the end of the lift rod, then turn the lower

nut counterclockwise. When the proper

adjustment is achieved, tighten the upper

nut to 25-30 ft-lbs. to secure in place.

6. The deck is properly leveled when both

blade tip measurements taken earlier are

equal.

Adjusting the Deck Height

The height of the deck can be adjusted to ensure that

the setting on your deck height lever is accurate. To

adjust the deck height proceed as follows:

1. Park the tractor on a firm, level surface

and place the deck lift lever in the

highest position (4”) and rotate the blade

nearest the discharge chute so that it is

perpendicular with the tractor.

2. Measure the distance from the outside of

the left blade tip to the ground and the

distance from the outside of the right blade

tip to the ground. Both measurements taken

should be 4”. If they’re not, proceed to the

next step.

3. Using the right and left lift rods, raise or

lower the necessary side of the deck until

both sides are measured at 4” from the

pavement.

Adjusting the Deck Wheels

WARNING

Keep hands and feet away from the discharge opening of

the deck.

Note: The deck wheels are an anti-scalp feature

of the deck and are not designed to support the

weight of the deck.

Loading ...

Loading ...

Loading ...