Loading ...

Loading ...

Loading ...

37

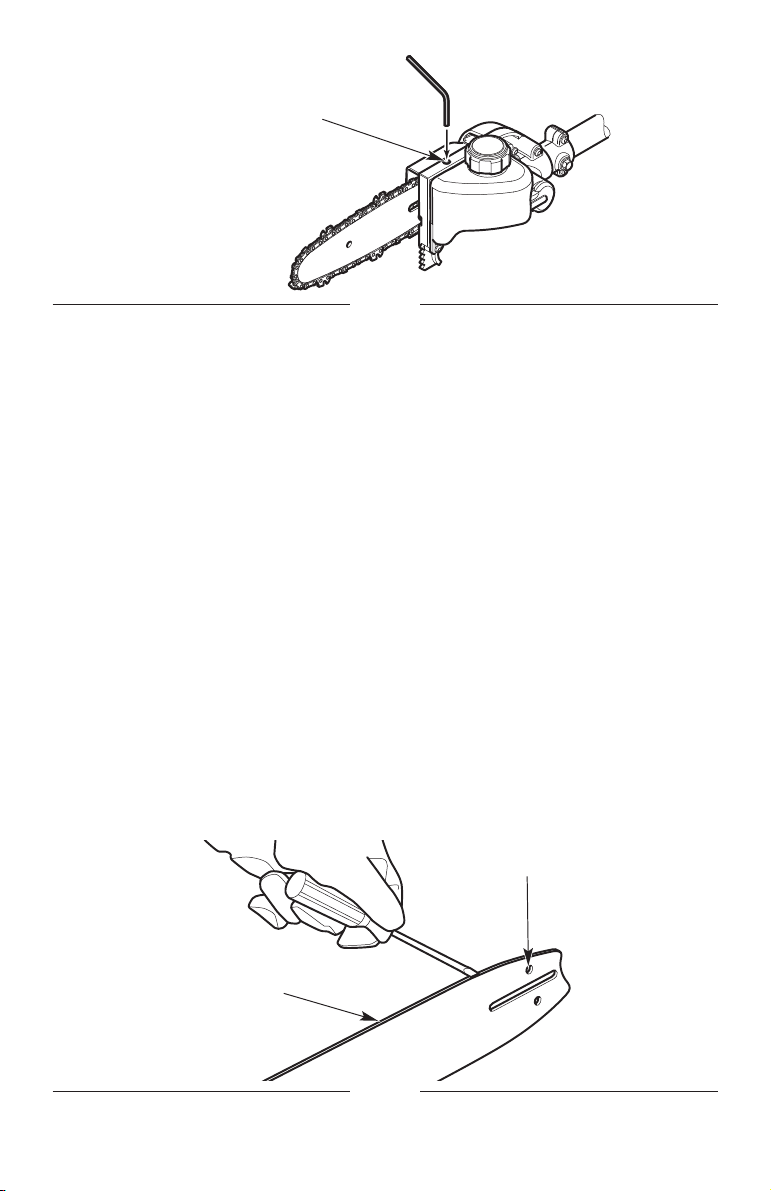

MAINTAINING THE GUIDE BAR

1. Rotate the guide bar frequently, at regular intervals (for example, after every 5 hours of operation),

to ensure even wear on the top and bottom of the guide bar. Refer to Removing and Installing the

Guide Bar and Saw Chain.

2. Clean the guide bar groove and oil passages whenever the saw chain is removed, when the unit

has been used heavily or when the saw chain appears dirty. Use a screwdriver, putty knife, wire

brush or similar instrument to remove debris from the guide bar groove (Fig. 23). Use a small, soft

wire to remove any debris from the chain oil discharge hole (Fig. 24).

NOTE: If the oil passages are clear, the saw chain will give o a spray of oil shortly after it begins to

rotate during operation.

3. Frequently check the guide bar for damage (Fig. 25). Feathering and burring of the guide bar rails

(the ridges on either side of the bar groove) is a normal process of guide bar wear. Such faults

should be smoothed with a le as soon as they occur (Fig. 25). A guide bar with the following faults

should be replaced:

• Wear inside the guide bar rails that permits the chain to lay sideways

• Bent guide bar

• Cracked or broken rails

• Spread rails

Refer to Replacing the Guide Bar and Saw Chain.

Fig. 22

Chain Oil

Adjustment Screw

Fig. 23

Guide Bar Groove

Oil Passage

Loading ...

Loading ...

Loading ...