Loading ...

Loading ...

Loading ...

20

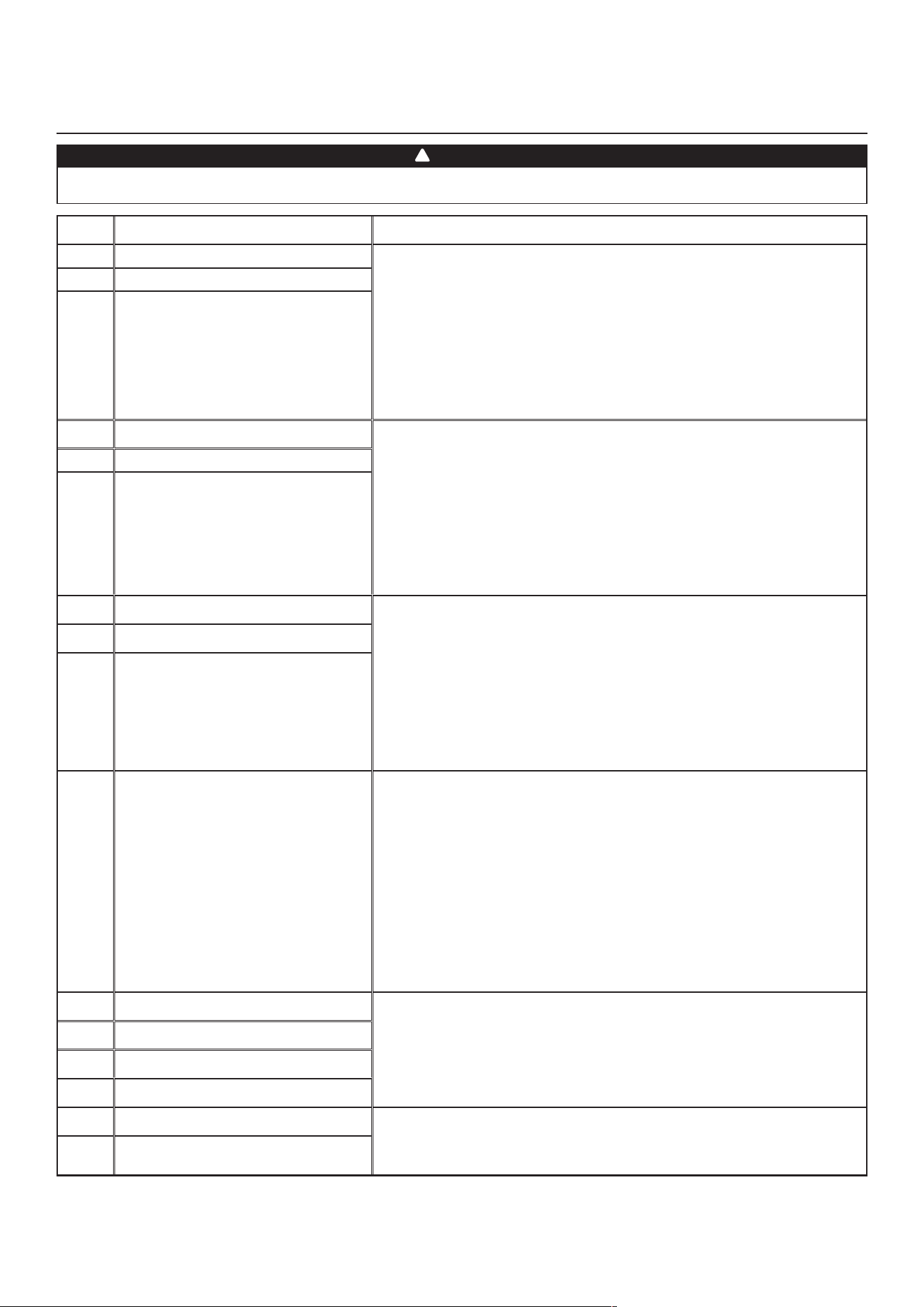

8. INSTALLER’S TROUBLESHOOTING

The wearing of safety glasses and gloves is recommended since a few diagnosis procedures may require the

unit to be in operation while proceeding. Be careful with moving and live parts to prevent any risk of injury.

WARNING

!

E

RROR

D

ESCRIPTION

S

OLUTION

E01

Supply damper range

STEP 1: Unplug unit, inspect the damper system, remove any undesirable

obstacle or dirt (fi lters and core may have to be removed to access the

damper system). Plug unit.

If STEP 1 did not fi x the problem, perform STEP 2: Open electrical

compartment, check if connector J5 (white) is well inserted, check for any

loose wires.

If STEP 2 did not fi x the problem, perform STEP 3: If the damper is not

moving at all, unplug J7 (red) from the electronic assembly, connect the

white damper system connector into J7. If the damper moves (but the

system still shows an error), the electronic assembly must be replaced.

Otherwise, replace the damper system.

E02

Supply damper timeout

E03

Supply damper

E05

Exhaust damper range

STEP 1: Unplug the unit, inspect the damper system, remove any undesirable

obstacle or dirt (fi lters and core may have to be removed to access the

damper system). Plug the unit.

If STEP 1 did not fi x the problem, perform STEP 2: Open electrical

compartment, check if connector J7 (red) is well inserted, check for any

loose wires.

If STEP 2 did not fi x the problem, perform STEP 3: If the damper is not

moving at all, unplug J5 (white) from the electronic assembly, connect the

white damper system connector into J5. If the damper moves (but the

system still shows an error), the electronic assembly must be replaced.

Otherwise, replace the damper system.

E06

Exhaust damper timeout

E07

Exhaust damper

E09

Recirculation damper range

STEP 1: Unplug the unit, inspect the damper system, remove any undesirable

obstacle or dirt (fi lters and core may have to be removed to access the

damper system). Plug the unit.

If STEP 1 did not fi x the problem, perform STEP 2: Open electrical

compartment, check if connector J6 (blue) is well inserted, check for any

loose wires.

If STEP 2 did not fi x the problem, perform STEP 3: If the damper is not

moving at all, unplug J5 (white) from the electronic assembly, connect the

blue damper system connector into J5. If the damper moves (but the system

still shows an error), the electronic assembly must be replaced. Otherwise,

replace the damper system.

E10

Recirculation damper timeout

E11

Recirculation damper

E22

Supply airfl ow

STEP 1: Unplug the unit. Perform a visual inspection of the supply damper

system. Clean fi lters, distribution registers and outside supply hood. Inspect

ducting to ensure it is not squeezed or bent. Plug the unit.

If STEP 1 did not fi x the problem, perform STEP 2: Remove ducting of the

supply path. On the LCD screen, select MAX to check if the unit is able to

reach the selected fl ow. If so, review the ducting path.

If STEP 2 did not fi x the problem, perform STEP 3: On the LCD screen, select

the MIN and MAX fl ow setting values then reset the unit. MAX fl ow value

will display on the LCD screen. If MAX fl ow is above desired MAX fl ow, set

MAX and MIN fl ows.

If STEP 3 did not fi x the problem, perform STEP 4: Replace the supply

blower and repeat STEP 3.

If STEP 4 did not fi x the problem, perform STEP 5: Replace the electronic

assembly.

E23

Supply motor (drive over current)

STEP 1: Unplug/plug unit.

If STEP 1 did not fi x the problem, perform STEP 2: Remove core and clear

the ventilation wheel from any dirt or obstacles.

If STEP 2 did not fi x the problem, perform STEP 3: Disconnect J2 (white) and

connect a spare blower system. If it works, replace supply blower.

If STEP 3 did not fi x the problem, perform STEP 4: Replace the electronic

assembly.

E27

Supply motor (drive foc duration)

E28

Supply motor (drive speed feedback)

E29

Supply motor (startup)

E24

Supply motor (drive over voltage)

STEP 1: Unplug/plug unit. Under and over voltage may be detected with

severe in-house power supply fl uctuation and stop the motor for protection.

If STEP 1 did not fi x the problem, perform STEP 2: Replace the electronic

assembly.

E25

Supply motor (drive under voltage)

Loading ...

Loading ...

Loading ...