Loading ...

Loading ...

Loading ...

16 SECTION 4 — PRODUCT CARE

Note: This Operator’s Manual covers several models.

Tractor features may vary by model. Not all features

in this manual are applicable to all tractor models and

the tractor depicted may differ from yours.

Warning! Before performing any

maintenance or repairs, disengage

the PTO, set the parking brake, stop

the engine and remove the key to

prevent unintended starting.

Troubleshooting

Excessive Vibration

1. Cutting blade loose.

• Tighten cutting blade and deck

spindle.

2. Cutting blade damaged, unbalanced or bent.

• Replace the cutting blade.

Uneven Cut

1. Deck not properly leveled.

• Perform side-to-side deck

adjustment.

2. Cutting blade dull or damaged.

• Sharpen or replace cutting blade.

3. Uneven tire pressure.

• Check and correct tire pressure in all

four tires.

Engine

Refer to the Engine Operator’s Manual for all

engine issues and questions.

Note : Maintenance, repair, or replacement of the

emission control devices and systems which are

being done at owner’s expense may be performed

by any engine repair establishment or individual.

Warranty repairs must be performed by an

authorized dealer.

Maintenance

Battery

WARNING

California PROPOSITION 65: Battery posts, terminals,

and related accessories contain lead and lead compounds,

chemicals known to the State of California to cause cancer

and reproductive harm. Wash hands after handling.

The battery is sealed and is maintenance-free.

Acid levels cannot be checked and fluid can not

be added.

• Always keep the battery cables and terminals

clean and free of corrosive build-up.

• After cleaning the battery and terminals,

apply a light coat of petroleum jelly or

grease to both terminals.

CAUTION

If removing the battery for cleaning, disconnect the NEGATIVE

(Black) wire from it’s terminal first, followed by the POSITIVE

(Red) wire. When re-installing the battery, always connect

the POSITIVE (Red) wire its terminal first, followed by the

NEGATIVE (Black) wire. Be certain that the wires are connected

to the correct terminals; reversing them could result in serious

damage to your engine’s alternating system.

Jump Starting

WARNING

Never jump start a damaged or frozen battery. Be certain

the vehicles do not touch, and ignitions are off. Do not

allow cable clamps to touch.

1. Connect positive (+) cable to positive (+)

post of your tractor’s discharged battery.

2. Connect the other end of the cable to the

positive (+) post of the jumper battery.

3. Connect the second cable negative (–) to

the other post of the jumper battery.

4. Make the final connection on the engine

block of the tractor, away from the battery.

Attach to an unpainted part to assure a

good connection.

CAUTION

If the jumper battery is installed on a vehicle (i.e. car,

truck), do NOT start the vehicle’s engine when jump starting

your tractor.

5. Start the tractor (as instructed in the

Operation section of this manual).

6. Remove the jumper cables in reverse order of

connection.

Charging

WARNING

Batteries give off an explosive gas while charging. Charge

the battery in a well ventilated area and keep away from an

open flame or pilot light as on a water heater, space heater,

furnace, clothes dryer or other gas appliances.

CAUTION

When charging your tractor’s battery, use only a charger

designed for 12V lead-acid batteries. Read your battery

charger’s Owner’s Manual prior to charging your tractor’s

battery. Always follow its instructions and heed its warnings.

If your tractor has not been put into use for an

extended period of time, charge the battery as follows:

1. Set your battery charger to deliver a max of

10 amperes.

2. If your battery charger is automatic, charge the

battery until the charger indicates that charging

is complete. If the charger is not automatic,

charge for no fewer than eight hours.

Fuse

WARNING

Before servicing, repairing, or inspecting, always disengage

PTO, set parking brake, stop engine and remove ignition key

to prevent unintended starting.

A 20 AMP fuse is installed in your tractor’s wiring

harness to protect the tractor’s electrical system

from damage caused by excessive amperage.

If the electrical system does not function, or your

tractor’s engine will not crank, check to be certain

that the fuse has not blown. It is located under the

seat, attached to the POSITIVE (Red) wire leading

to the battery.

CAUTION

Always use a replacement fuse with the same amperage

capacity as the blown fuse.

Relays & Switches

There are several safety switches in the electrical

system. If a function of the safety interlock system

described earlier is not functioning properly, have

the electrical system checked by your authorized

service dealer.

Engine

Refer to the Engine Operator’s Manual for all

engine maintenance procedures and instructions.

Note: If the “LOW OIL” text appears immediately after

the engine is started the oil pressure may be low. This

is normal. If the low oil indication persists stop the

tractor immediately and check the engine oil level as

instructed in the Engine Operator’s Manual.

Note: The “Low Oil” function only works if the

engine is equipped with an oil pressure switch.

Changing the Engine Oil

WARNING

If the engine has been recently run, the engine, muffler and

surrounding metal surfaces will be hot and can cause burns

to the skin. Exercise caution to avoid burns.

Note: The oil filter should be changed at every

oil change interval. To complete an oil change,

proceed as follows:

To complete an oil change, proceed as follows:

1. Run the engine for a short time to warm

the engine oil. The oil will flow more freely

and carry away more impurities. Use care to

avoid burns from hot oil.

2. Open the tractor’s hood and locate the oil

drain port on the side of the engine.

3. Place an appropriate oil collection container

with at least a 2.5 quart capacity below the

opening of the oil drain tube, to collect the

used oil. Remove the oil fill cap/dipstick

from the oil fill tube.

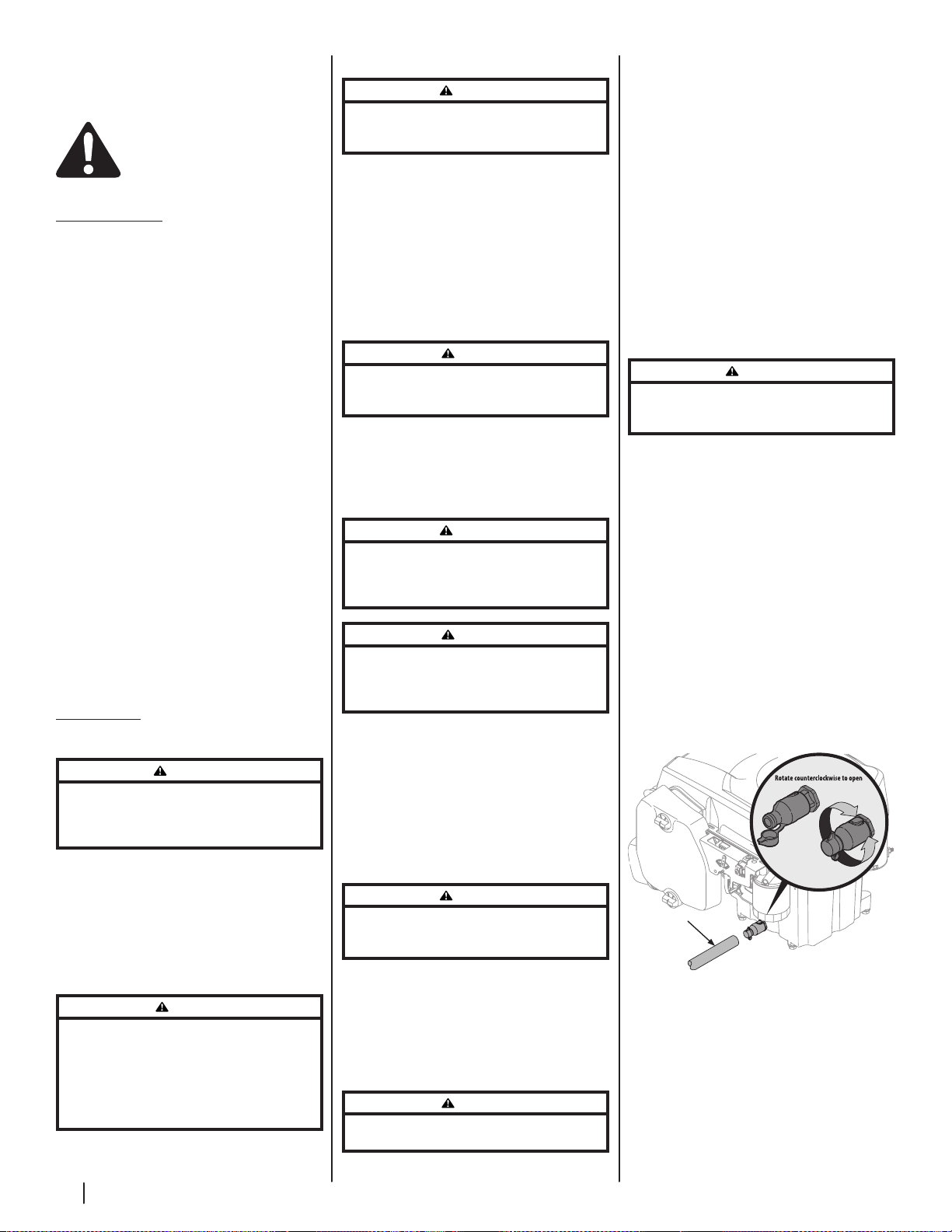

4. Pop open the protective cap on the end of

the oil drain valve to expose the drain port.

See Figure 4-1.

OPENED

CLOSED

Clear Oil Drain Tube

Figure 4-1

5. Remove the oil fill cap/dipstick from the oil

fill tube.

6. Push the clear oil drain tube (packed with this

manual) onto the oil drain port. Route the

opposite end of the tube into an appropriate

oil collection container with at least a 2.5

quart capacity to collect the used oil.

Loading ...

Loading ...

Loading ...