Loading ...

Loading ...

Loading ...

23WWW.SENIXTOOLS.COM

7. Tighten the bar mounting nuts to fix the clutch cover

(Fig. 35).

8. Pull the saw chain along the top of the guide bar by

hand from one end to the other, several times. The

chain should feel tight but still move freely.

Fig. 35

Fig. 36

Fig. 37

Saw chain sharpening may be required:

- after damp wood is cut (mealy sawdust),

- when handling the product becomes difficult (pulls to

the left or right),

- when the saw chain is blunt (excessive force is

required to penetrate the wood), or obviously

damaged.

Never saw with a blunt chain. The saw chain is blunt if

you have to push the product into the tree and the chips

are very small.

1. Have the saw chain sharpened professionally at

an authorized service center or sharpen the chain

yourself by using a proper sharpening kit. Also

observe the sharpening instructions supplied with

the sharpening kit.

2. The height difference between the tooth and the

ridge is the cutting depth. When sharpening the saw

chain you have to consider the following points:

- File angle

- Cutting angle

- File position

- Diameter of round file

- File depth

3. To sharpen the chain proceed as follows:

- Use protective gloves.

- Ensure the chain is correctly tensioned.

- Engage the chain brake to lock the chain on the

bar.

Only sharpen the saw chain yourself if you are trained

and have experience! Use proper tools to sharpen the

saw chain!

A file guide is available from most reputable tool

merchants and is the easiest way to hold the file at the

correct position.

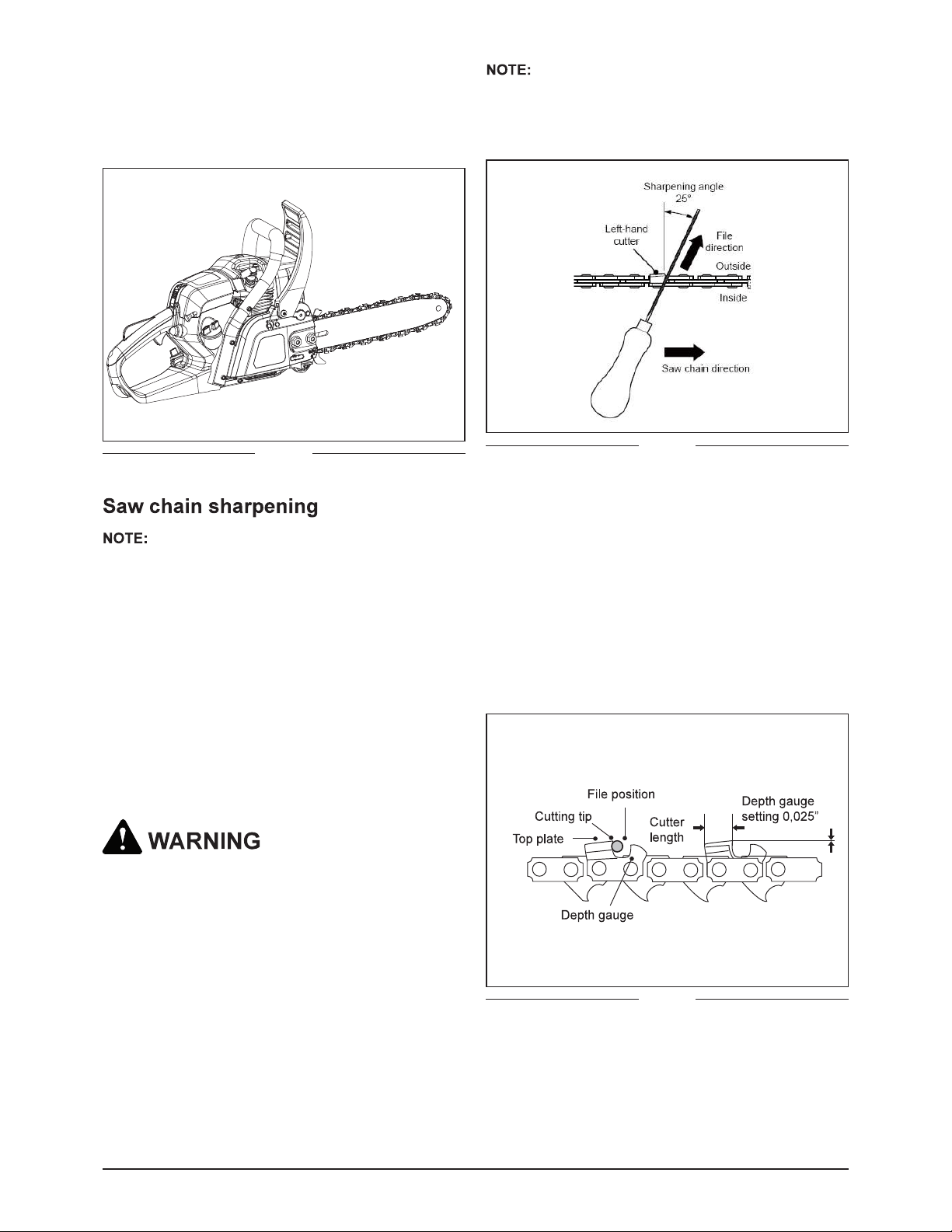

4. File at an angle perpendicular to the bar, and at an

angle of 25° to the direction of travel(Fig.36).

5. File each tooth from the inside towards outside only.

File one side of the chain first than turn the saw

around and repeat the process.

6. Sharpen each tooth equally by using the same

number of strokes.

7. Keep all cutter lengths equal. Check the safety

depth gauge height every 5 sharpenings. If the

depth gauges are also trimmed it is essential that

the original profile be restored.

8. Use a depth gauge measuring instrument to

check the height of the depth gauge. Depth gauge

measuring jigs are available from most reputable

tool merchants (Fig.37).

Loading ...

Loading ...

Loading ...