Loading ...

Loading ...

Loading ...

JET

7

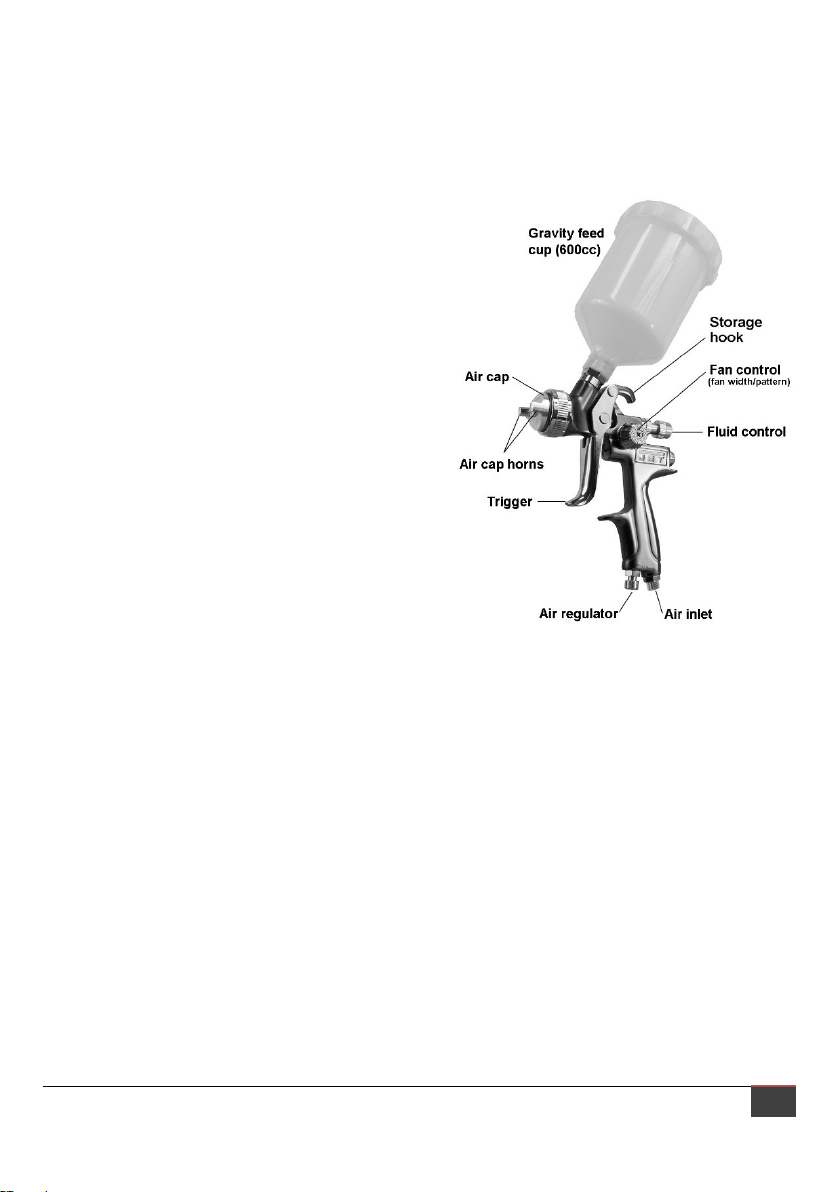

Setup and Assembly

Any missing parts or damage should be reported

immediately to your JET

®

distributor. Do not use a

damaged tool. Read this instruction manual

thoroughly for operation, maintenance and safety

instructions.

Box contents:

1 Spray gun

1 Gravity feed cup, 600cc

1 Nylon strainer

1 Spanner

1 Bristle brush

1 Operation and parts manual

1 Warranty card

Operation

1. Blow out air line to remove any dirt or

moisture, then connect air supply hose to

tool’s air inlet.

IMPORTANT: Connecting a quick-change

coupling directly to the tool is not

recommended, as vibration may cause the

connection to fail. Instead, add a leader hose

and install any quick-change couplings

farther down the line.

2. Unscrew cup lid and add fluid to be sprayed.

(Follow paint manufacturer’s instructions for

proper mixing.)

3. Set regulator to desired air pressure. (Refer

to gun’s rated maximum pressure).

4. Loosen air cap knurled ring and rotate air cap

horns to effect horizontal or vertical spray.

Retighten air cap.

Horizontal horns (as shown in Figure 1) will

produce vertical pattern for side-to-side

motion. Vertical horns produce horizontal

pattern used for top-to-bottom motion.

5. Squeezing trigger part way opens air valve.

Squeezing further retracts fluid needle, thus

releasing fluid where it is atomized by the air

flowing through air cap.

6. Rotate fluid control knob clockwise to

decrease flow of material, counterclockwise

to increase.

7. Rotate fan control knob counterclockwise for

full, flat spray pattern; clockwise for narrower

pattern.

NOTE: To reduce overspray and obtain maximum

efficiency, always spray with the lowest possible

air pressure/fluid flow combination.

Figure 1

Spray gun movement

The gun should be held perpendicular to surface

being covered, and moved parallel with it at a

consistent pace. See Figure 2. The stroke should

be started before the trigger is pulled, and the

trigger released before the stroke is ended.

Distance between gun and surface should be 6 to

12 inches depending upon material and atomizing

pressure.

Deposited material should be even and wet. Lap

each stroke over the preceding stroke from 1/3 to

1/2, to obtain a uniform finish.

Loading ...

Loading ...

Loading ...