Loading ...

Loading ...

Loading ...

8

5. Maintenance (cont’d)

5.2 Annual Maintenance

Annual maintenance should include:

AIR FILTERS

Vacuum and wash standard foam lters. Replace medium ef ciency lter if present.

D

RAIN PANS AND INTERIOR OF UNIT

Wash the foil faced insulation surfaces and wipe the drain pans with a soft cloth and mild cleaning solution. Check the drain ttings to

ensure they are draining freely.

R

ECOVERY CORE

The recovery core must be handled with care. It is recommended that it be washed once a year following the season of most intense

use, in order to ensure maximum ef ciency of the partitions.

F

ANS

Blower wheels and fan housing should be checked for dirt build-up. If they appear dirty, it may be necessary to remove the blower

assembly and then vacuum the dust out through the fan mouth. See next page for instructions on removing the blower assembly.

WARNING

!

Risk of electric shocks. Before performing maintenance or repairs, always stop the unit, then turn power off at

service panel. The wearing of safety glasses and gloves is recommended when handling unit components to

prevent injuries caused by sharp edges.

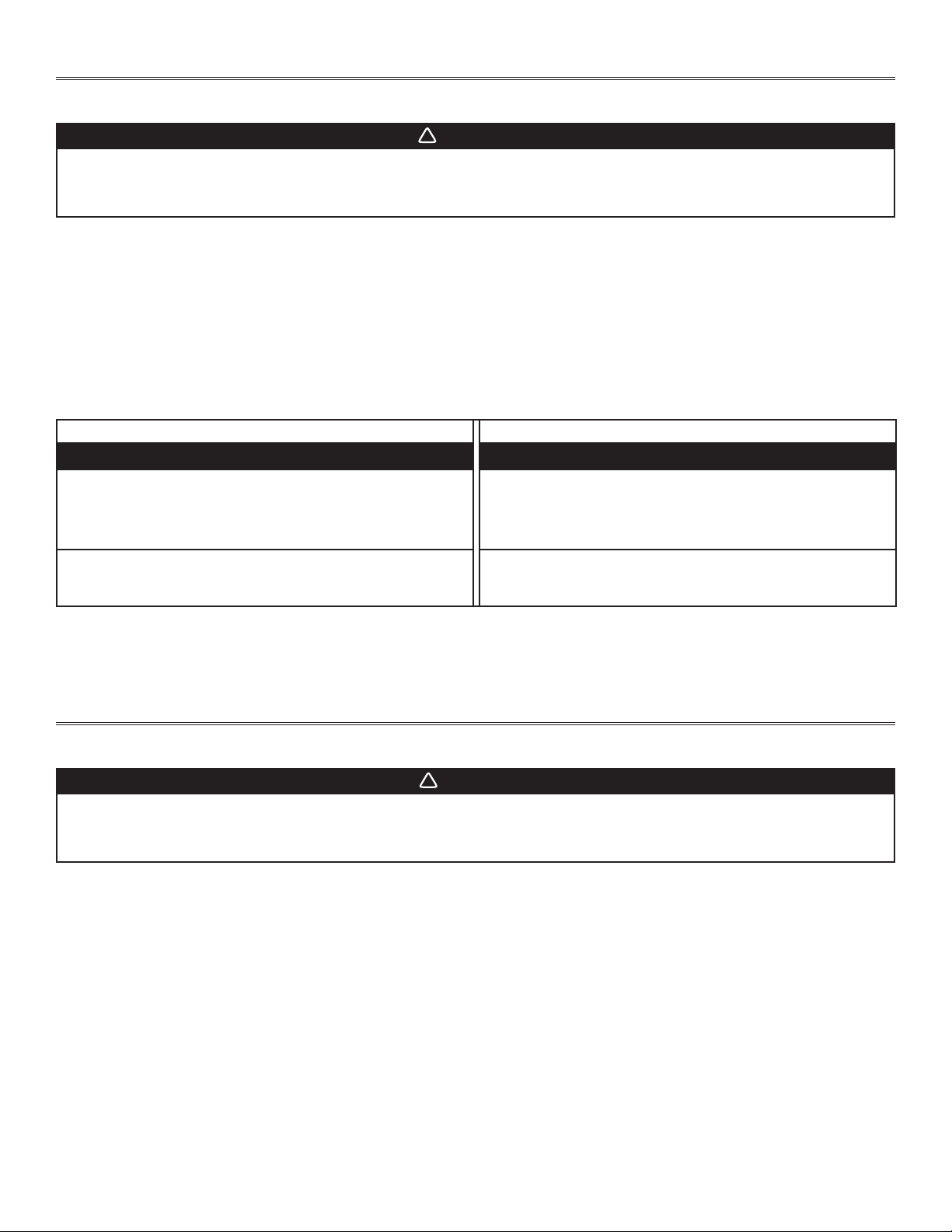

HEAT RECOVERY CORE ERV HM CORE

CAUTION CAUTION

Hot water and a strong cleaning agent could damage

the polypropylene core. Ensure the core is returned to

the unit in the correct orientation. Use the sticker as a

guide.

Do not soak the ERV HM core in water. This core can

easely be damaged especially if it is soaked.

Allow the heat recovery core to soak for three hours in warm water

and mild soap. Rinse under a heavy stream of water.

For ERV HM core, use a vacuum cleaner or low pressure air jet. It

is not recommended to use solvents or detergents as these may

damage the media or structure of the core.

6. Service

6.1 Parts Replacement

SYSTEM OPERATION CHECK

Veri cation of all control modes should be checked to ensure proper operation. Refer to 3.2 Sequence of Operation section.

TESTING AND REPLACEMENT OF THE DAMPER ACTUATOR

Check damper operation by switching between LOW - COM or HIGH - COM on the dry contact terminal or by switching through the

modes on the optional remote wall control. If the damper does not respond in one or both directions, check all connections.

CAUTION: 120 VAC. Check for 120 volt output across the WHITE/BLACK wires. If 120 volts can be measured at the motor, replace

the motor. If 120 volts cannot be measured at the motor, check pins J1-9 at the printed circuit board.

M

AIN CIRCUIT BOARD REPLACEMENT

The main circuit board must be replaced if an electronic problem arises. For example, the unit suddenly stops, the unit stays in defrost

all of the time or if control functions are not working properly. Ensure that power is reaching the board. Test the blower motors and

damper actuators for operation when directly connected to the appropriate power voltage. If the motor and damper actuators function

normally, replace the main circuit board.

WARNING

!

High voltage, risk of electric shocks. Only quali ed service personnel should service this equipment. The wearing

of safety glasses and gloves is recommended since a few diagnosis procedures may require the unit to be in

operation while proceeding. Be careful with moving and live parts to prevent injuries.

Loading ...

Loading ...

Loading ...