Loading ...

Loading ...

Loading ...

ENGLISH

www.stiebel-eltron.com WWK222-302 H | 17

INSTALLATION

Troubleshooting

13. Troubleshooting

WARNING Electrocution

Troubleshooting work must only be carried out by a

qualified contractor. Prior to all work on the appliance,

isolate it from the power supply.

!

Material losses

If you disconnect the appliance from the power supply, it

is no longer protected against frost or corrosion.

Only disconnect the appliance from the power sup-

ply for longer periods if you are also draining the

DHW cylinder.

For work inside the appliance, remove the appliance cover

(see chapter "Cleaning and maintenance/ Removing the ap-

pliance cover").

If necessary, remove the upper section of the casing jacket

(see chapter "Maintenance and cleaning/ Removing the cas-

ing ring").

Note

Refit the casing ring after completing the work. See chap-

ter "Maintenance and cleaning/ Fitting the casing ring").

Note

Following an interruption of the power supply, compres-

sor operation remains blocked for at least one minute

while the appliance initialises.

If the compressor subsequently fails to start, it may be

blocked by additional safety devices (motor overload

relay, high pressure switch). This block can last between

1 and 10minutes.

Fault Cause

Remedy

No hot water is

available.

The impressed current

anode is faulty.

Replace the impressed current

anode.

The compressor

switches off un-

expectedly.

The application limits

have been exceeded or

undershot.

No action required.

Excessive pressure in the

refrigerant circuit. The

safety pressure limiter

has responded 5 times in

5 hours. The compressor

has been switched off.

Eliminate the cause of the

increase in pressure in the

refrigerant circuit. Wait ap-

prox.5-15minutes for the appli-

ance to equalise the pressure.

The appliance can only be un-

blocked using a service program-

ming unit.

The heating

output of the

appliance has

reduced.

An inadequate air flow

across the evaporator is a

possible cause.

Check whether the fan is contam-

inated. Check whether the evap-

orator is contaminated. Ensure

that the supply and extract air

flow are unimpeded.

13.1 Resetting the safety pressure limiter

The safety pressure limiter responds if the pressure in the re-

frigerant circuit exceeds the permissible maximum value. If the

safety pressure limiter responds 5 times in 5hours, compressor

operation is blocked.

Eliminate the cause of the increase in pressure in the refrig-

erant circuit

Wait approx.5-15minutes for the appliance to equalise the

pressure.

The appliance can only be unblocked using a service program-

ming unit.

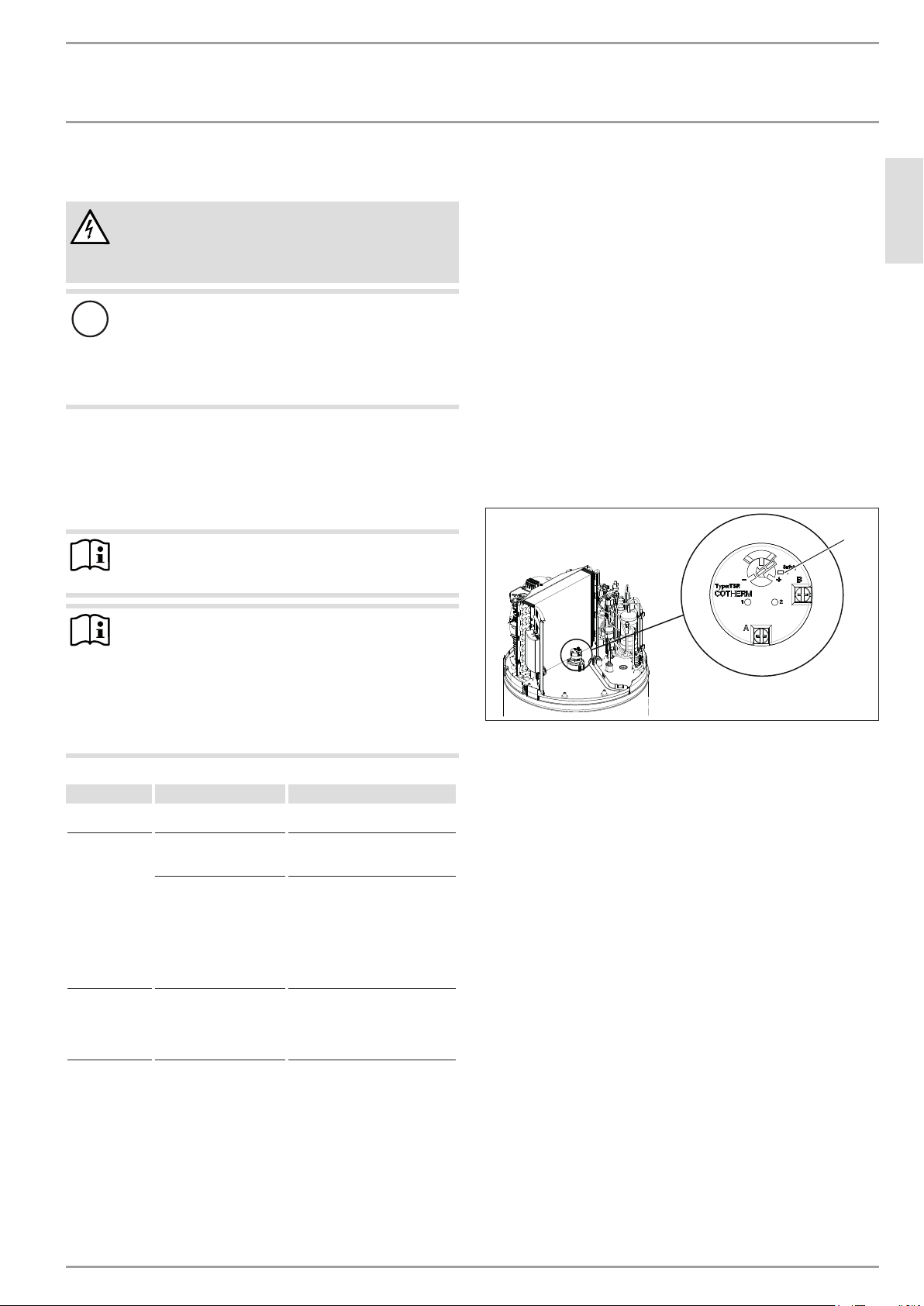

13.2 WWK222H/ WWK 302H: Resetting the high

limit safety cut-out

If the DHW cylinder is overheated, the high limit safety cut-out

switches off the electric emergency/booster heater to protect the

appliance.

D0000039352

1

1 Reset button for high limit safety cut-out

Once the cause of the fault has been removed, press the reset

button of the high limit safety cut-out on the rod thermostat.

To do so, remove the appliance cover.

13.3 Motor overload relay

The motor overload relay will shut down the compressor in the

case of excessive thermal load.

Remove the cause.

After a short cooling period, the motor overload relay will restart

the compressor automatically.

Loading ...

Loading ...

Loading ...