Loading ...

Loading ...

Loading ...

It may be necessary to brace or support one

end of the outfit when attaching the wheels

and the foot extension bracket because the

outfit will have a tendency to tip over before

wheels are attached.

1. insert the handle into pockets under the tank base.

Put one set screw (22) through hole in one side of

tank base and tighten down on handle.

2. Remove the protective paper strip from the adhesive

backed rubber foot strip (45). Attach the rubber foot

strip to the bottom of the foot extension bracket (43)

or tank teg. Press firmly into place.

3. Attach foot extension bracket (43) to the air tank breck-

. et. Use one cap screw (44), one Iockwasher (87) and

one hex nut (42) at each end. Tighten. (Model

9!9.174320 only)

4. Attach one wheel (38) to each side of the outfit. Use

one shoulder bolt (39) and one hex nut with lock

washer (40) for each wheel. Tighten securely. Use

the bracket lower bolt hole for attaching the wheels

on model 919.174320.

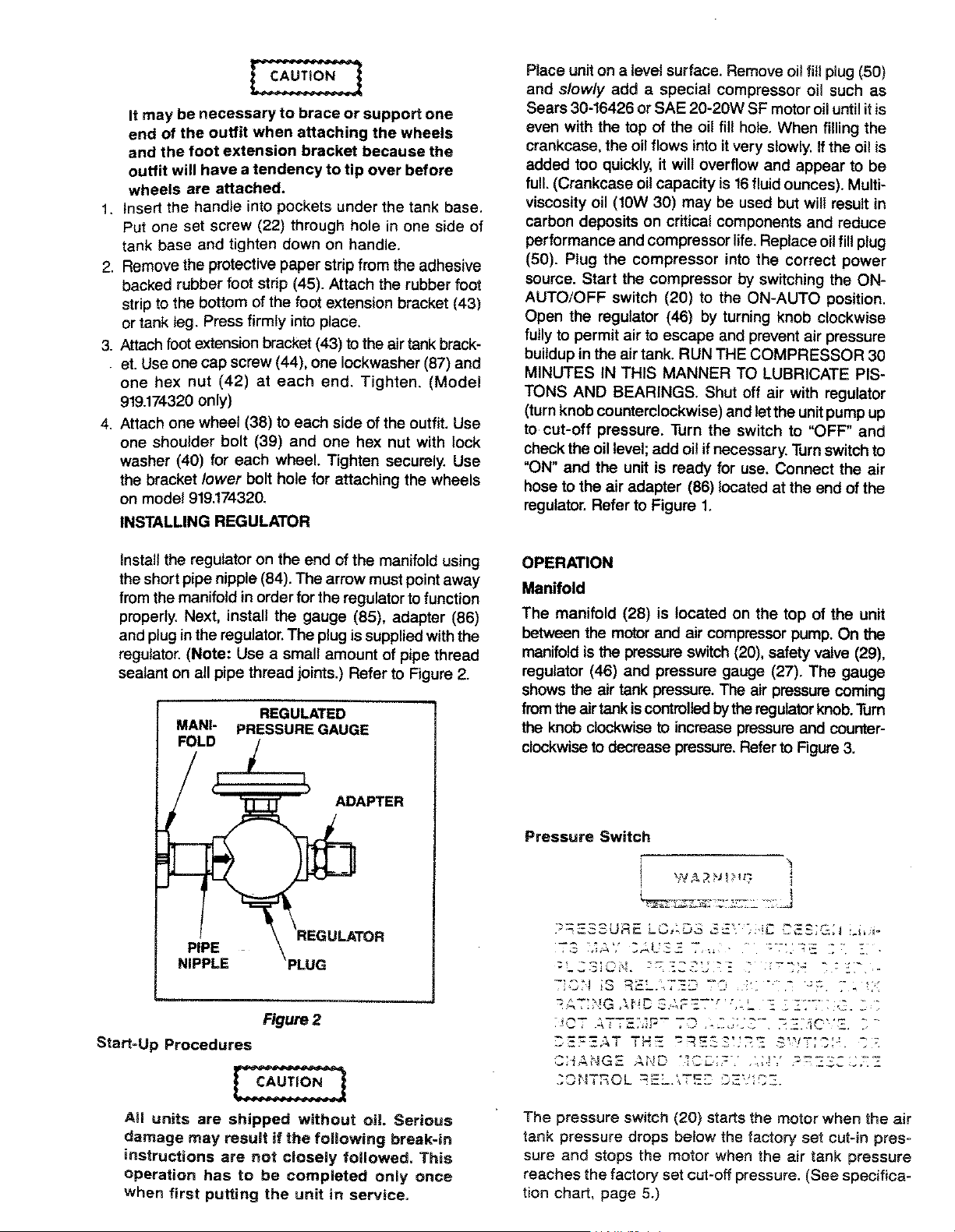

INSTALLING REGULATOR

install the regulator on the end of the manifold using

the short pipe nipple (84). The arrow must point away

from the manifold in order for the regulator to function

properly. Next, install the gauge (85), adapter (86)

and plug in the regulator. The plug is supplied with the

regulator. (Note: Use a small amount of pipe thread

sealant on all pipe thread joints.) Refer to Figure 2.

REGULATED

MANI- PRESSURE GAUGE

FOLD

ADAPTER

REGULATOR

PIPE

NIPPLE

Figure 2

Start=Up Procedures

All units are shipped without oi!. Serious

damage may result if the following break-in

instructions are not closely followed. This

Operation has to be completed only once

when first putting the unit in service.

Place uniton a level surface. Remove oit fill plug (50)

and slowly add a special compressor oil such as

Sears 30-16426 or SAE 20-20W SF motor oil until itis

even with the top of the oil fill hole. When filling the

crankcase, the oil flows into itvery slowly. If the oil is

added too quickly, it wilt overflow and appear to be

full. (Crankcase oil capacity is 16 fluid ounces). Multi-

viscosity oil (10W 30) may be used but will result in

carbon deposits on critical components and reduce

performance and compressor life. Replace oil fill plug

(50). Plug the compressor into the correct power

source• Start the compressor by switching the ON-

AUTO/OFF switch (20) to the ON-AUTO position.

Open the regulator (46) by turning knob clockwise

fully to permit air to escape and prevent air pressure

buildup in the air tank. RUN THE COMPRESSOR 30

MINUTES IN THIS MANNER TO LUBRICATE PIS-

TONS AND BEARINGS. Shut off air with regulator

(turn knob counterclockwise) and let the unit pump up

to cut-off pressure. Turn the switch to "OFF" and

check the oil level; add oil if necessary. Turn switch to

"ON" and the unit is ready for use. Connect the air

hose to the air adapter (86) located at the end of the

regulator. Refer to Figure 1.

OPERATION

Manifold

The manifold (28) is located on the top of the unit

between the motor and air compressorpump. On the

manifold is the pressure switch (20), safety valve (29),

regulator (46) and pressure gauge (27). The gauge

shows the air tank pressure. The air pressure coming

from the airtank iscontrolled bythe regulator knob. Turn

the knob clockwise to increase pressure and counter-

clockwise to decrease pressure. Refer to Figure 3.

Pressure Switch

:'_gS;C_I. "_= ....... - ..........

7_C I iS .......... = ...... " - _ " ""

:' &T:b!G AHC _ 1_=-'f ....

" +'-ATTE:,';F"-_ ............ ' ....

H-F-%T TH- -_=-_............ =w--'"•: _-

........ qG,- AND ............ '.............

The pressure switch (20) starts the motor when the air

tank pressure drops below the factory set cut-in pres-

sure and stops the motor when the air tank pressure

reaches the factory set cut-off pressure. (See specifica-

tion chart, page 5.)

Loading ...

Loading ...

Loading ...