Loading ...

Loading ...

Loading ...

ENGLISH

8

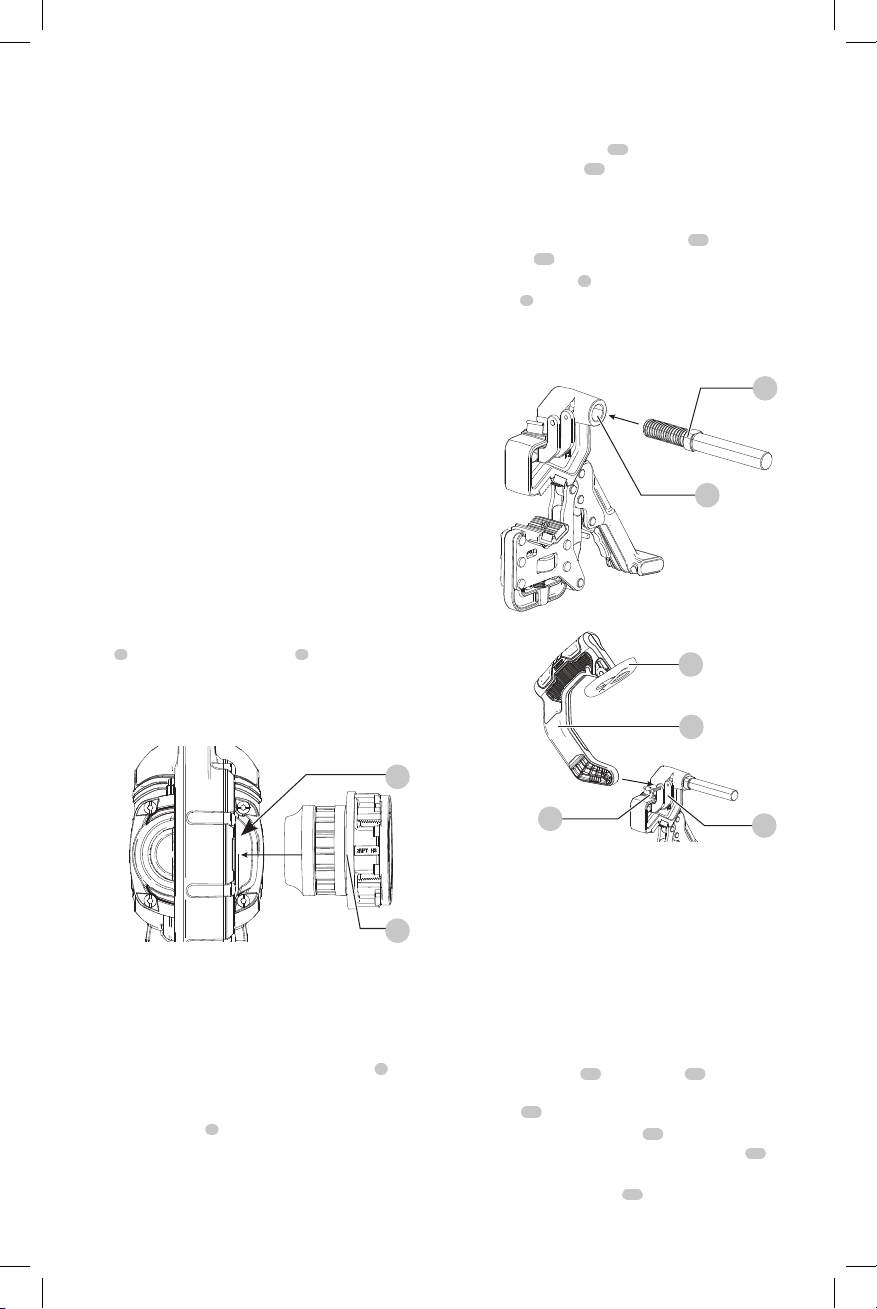

Removing Die (Fig. B)

NOTE: If the die becomes stuck use a piece of wood or

a dead blow hammer to remove the die from the die

interface. Do not use metal tool to remove the die. Metal

tools could damage the dieinterface.

1. Place the pipe threader on a flat surface. The die

6

should be facing down.

2. Using both hands with equal pressure, push the die out

of the die interface

7

and free from the frictionhold.

Fig.B

6

7

Attaching the Die (Fig. B)

WARNING: Inspect the cutterheads of the die for

wear, deformation, chips or other issues. Dull or

damaged cutterheads increase the amount of force

required, produce poor quality threads and increase

the risk of injury. Only use

DEWALT

recommended dies.

Other dies may not fit correctly, increasing the risk of

damage or personal injury.

1. Insert the die on the side of the tool as shown in Fig.B.

2. Using both hands with equal pressure, push the

die

6

inside the die head interface

7

until the ridge

of the die head sits flush against the ridge of the die

headinterface.

3. Rotate the die slightly so the latch engages.

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of serious personal

injury, turn unit off and remove the battery pack

before making any adjustments or removing/

installing attachments or accessories. An

accidental start-up can causeinjury.

Mounting Clamp to Pipe (Fig. E, K)

WARNING: Properly support the pipe in a stand or

securely brace in place to reduce the risk of the pipe

falling ortipping.

WARNING: Always attach the clamp before using the

pipethreader.

WARNING: Always use the die arm when starting

the thread as shown in Proper Hand Position.

Do not substitute your hand for the die arm to start

thethread.

1. Set the adjustment

11

on the clamp

12

for the

appropriate pipe diameter following the size

indicator

28

.

2. Place the clamp over the pipe

20

so that the end of

the pipe aligns with the end of the support arm

10

as

in Fig K.

3. Put pressure on the clamp

12

to properly secure it to

the pipe. If not secure, make any needed adjustments

Intended Use

The pipe threader is designed for threading pipe and

conduit using appropriate cutting dies.

DO NOT use for drilling or driving fasteners.

DO NOT use under wet conditions or in presence of

flammable liquids orgases.

This pipe threader is a professional power tool.

DO NOT let children come into contact with the tool.

Supervision is required when inexperienced operators use

thistool.

Fig.C

10

27

Assemble Clamp (Fig. C, D)

Assemble Support Arm

1. Thread the support arm

10

completely through the

support arm mount

27

.

2. Tighten the support arm with an open end wrench.

Assemble Die Arm

1. Unthread the preassembled wing nut

18

from the die

arm saddle

17

.

2. Attach the die arm

8

to the die arm saddle with the the

die plate

9

facing toward the end of the pipe. Thread

and tighten the preassembled wing nut to secure the

die arm intoplace.

Fig.D

9

8

17

18

Loading ...

Loading ...

Loading ...