Loading ...

Loading ...

Loading ...

23

SERVICE AND MAINTENANCE

Oil Drain Hose

Square-Head

Hose Plug

Figure 24

5. Twist-and-pull oil drain (refer to Figure 23):

a. Pop open the protective cap on the end of the oil drain valve to

expose the drain port.

b. Remove the oil fill cap/dipstick from the oil fill tube.

c. Push the clear oil drain tube (packed with this manual) onto the oil

drain port. Route the opposite end of the tube into an appropriate oil

collection container with at least a 2.5 quart capacity to collect the

used oil.

d. The engine is equipped with a twist-and-pull drain port. Turn the oil

drain valve ⁄-turn counter-clockwise, then pull outward to begin

draining oil. After the oil has finished draining, push the end of the

oil drain valve back in and turn ⁄-turn clockwise to secure it back

in place. Re-cap the end of the oil drain valve to keep debris from

entering the drain port.

e. Skip ahead to Step 7.

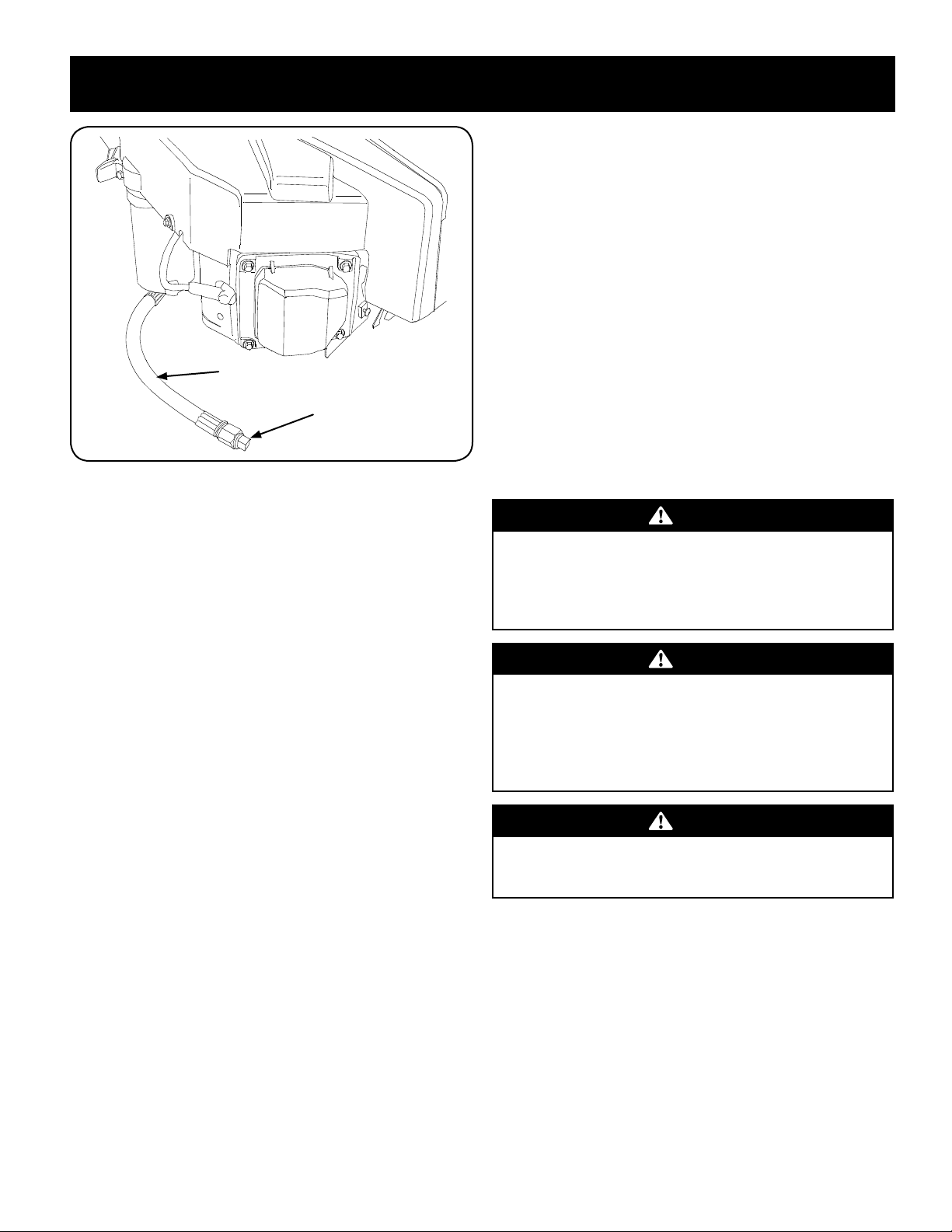

6. Removable square-head hose plug (See Figure 24):

a. Remove the square-head hose plug from the end of the hose. See

Figure 24. Drain the engine oil into the collection container.

b. After draining the oil, wipe any residual oil from the oil drain hose.

Replace the square-head hose plug on the drain hose and fully

tighten.

c. Continue with Step 7.

7. Replace the oil filter, and refill the engine with new oil as instructed in the

engine operator’s manual.

8. To refill the oil, re-install the plug at the end of the tube and refer to the

engine operator’s manual for refilling instructions, oil type and amount.

NOTE : Maintenance, repair, or replacement of the emission control devices

and systems which are being done at owner’s expense may be performed

by any engine repair establishment or individual. Warranty repairs must be

performed by an authorized dealer

Tire Maintenance

Check the tire air pressure after every 50 hours of operation or weekly. Keep the

tires inflated to the recommended pressures. Improper inflation will shorten the

tire service life. See the tire side wall for proper inflation pressures. Observe the

following guidelines:

• Do not inflate a tire above the maximum pressure shown on the sidewall of

the tire.

• Do not reinflate a tire that has been run flat or seriously under inflated. Have

a qualified tire mechanic inspect and service the tire.

Lubrication

• Using a pressure lubricating gun, lubricate the front castor wheel axles and

the front pivot axle with No. 2 multipurpose lithium grease after every 10

hours of service.

• Periodically lubricate all other pivot points; i.e. the seat pivot bracket, idler pivot

bracket on the deck, deck lift shaft assembly, etc. with a quality lubricating oil.

General Battery Information

WARNING

Should battery acid accidentally splatter into the eyes or onto the skin,

rinse the affected area immediately with clean cold water. If there is

any further discomfort, seek prompt medical attention. If acid spills on

clothing, first dilute it with clean water, then neutralize with a solution of

ammonia/water or baking soda/water.

WARNING

NEVER connect (or disconnect) battery charger clips to the battery while

the charger is turned on, as it can cause sparks. Keep all sources of ignition

(cigarettes, matches, lighters) away from the battery. The gas generated

during charging can be combustible. As a further precaution, only charge

the battery in a well ventilated area. Always shield eyes and protect skin

and clothing when working near batteries.

WARNING

Batteries contain sulfuric acid and may emit explosive gases. Use extreme

caution when handling batteries. Keep batteries out of the reach of

children.

Battery Maintenance

The battery is filled with battery acid and then sealed at the factory. However, even a

“maintenance free” battery requires some maintenance to ensure its proper life cycle.

• Spray the terminals and exposed wire with a battery terminal sealer, or coat

the terminals with a thin coat of grease or petroleum jelly, to protect against

corrosion.

• Always keep the battery cables and terminals clean and free of corrosion.

• Avoid tipping. Even a sealed battery will leak electrolyte when tipped.

Loading ...

Loading ...

Loading ...