Loading ...

Loading ...

Loading ...

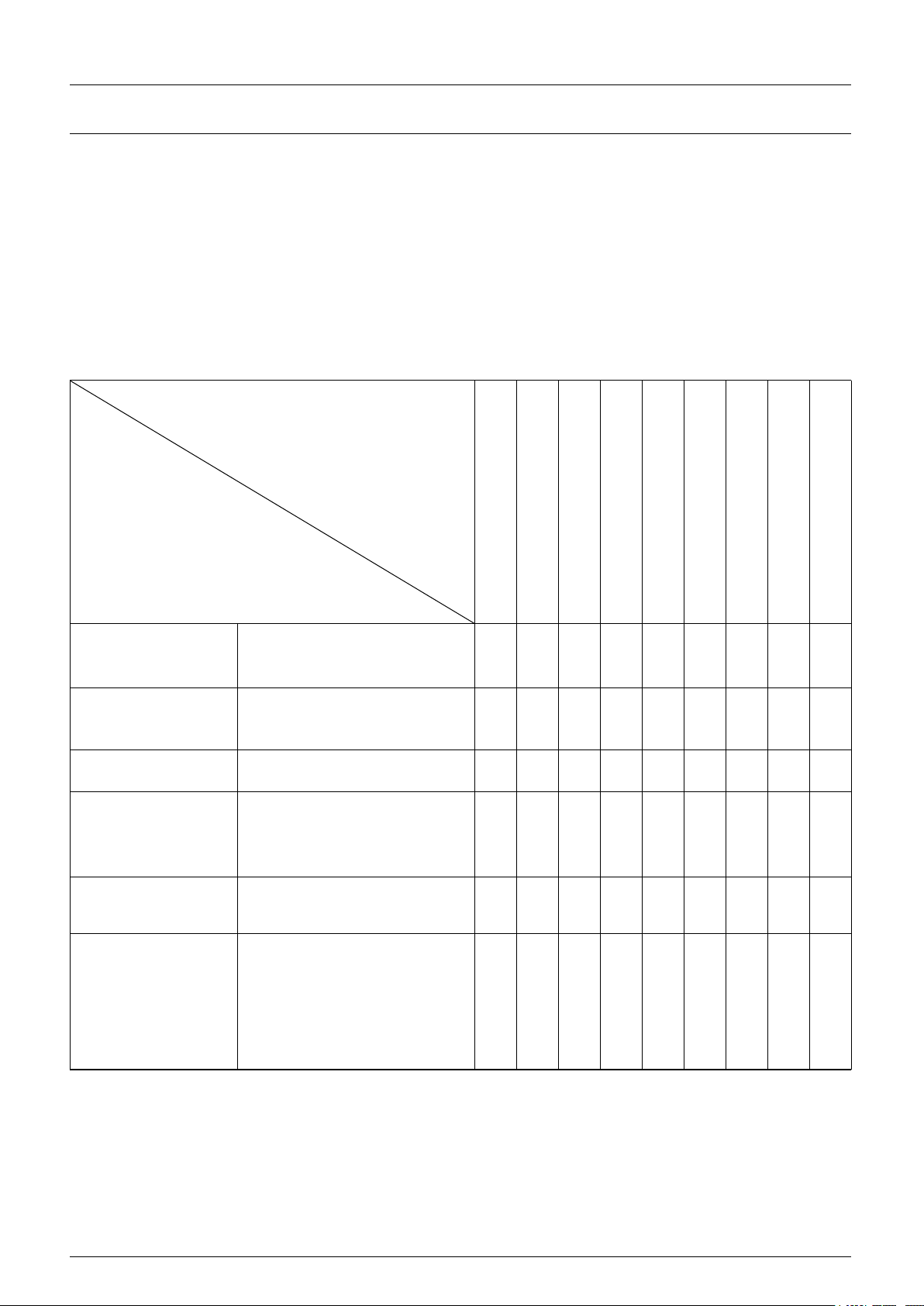

CHECK FAULTS

When abnormal situation such as failure of welding, unstable arc, poor welding result, do not

consider that it must be some faults.

The machine may be well but just some reasons cause abnormality such as that some connectors

are loosened, forget to turn on the switch, wrong setting, broken cable and gas pipe, etc. So before

maintenance, Please check it up first, some problem may be solved.

The following is earlier checking diagram by this way. In the top right corner item you can find the

problem, please check according to the diagram for the one with “O” mark.

EARLIER CHECKING DIAGRAM FOR THE ABNORMAL

The abnormal

Place and item to be checked

No arcing

No gas

Can not Send wire

Poor Arcing initiation

Unstable arc

Welding margin unclean

Wire and Material conglutinated

Wire links Electric leading hole

fcon conglutinated

Have air hole

Power supply box

(input protective

set )

1、connected or not

2、fuse broken

3、connector loosen

〇

〇

〇

〇

〇

〇

Input cable

1、 Broken or not

2、 Connector loosen

3、overheat

〇

〇

〇

〇

〇

〇

Power

1、 Switched or not

2、lack phase

〇

〇

〇

〇

〇

〇

〇

〇

Gas cylinder&adjuster

1、open cover

2、remains of gas

3、flow setting volume

4、Connecting point loosen

〇

〇

Gas pipe (access from

the high-pressure

cylinder to torch)

1、 Connecting point loosen

2、 Pipe broken

〇

Wire sending

equipment

1、 Wheel and leading tube not

match

2、 Wheel broken, slot blocked

or lack

3、 Over pressing or loosen,

powder store up in entrance

of SUS tube

〇

〇

〇

〇

〇

Loading ...

Loading ...