Loading ...

Loading ...

Loading ...

ENGLISH

11

Symbol Mode Application

Hammerdrilling

Drilling into concrete

and masonry

Hammering

only

Lightchipping

Drilling

Drilling into metal,

wood and masonry

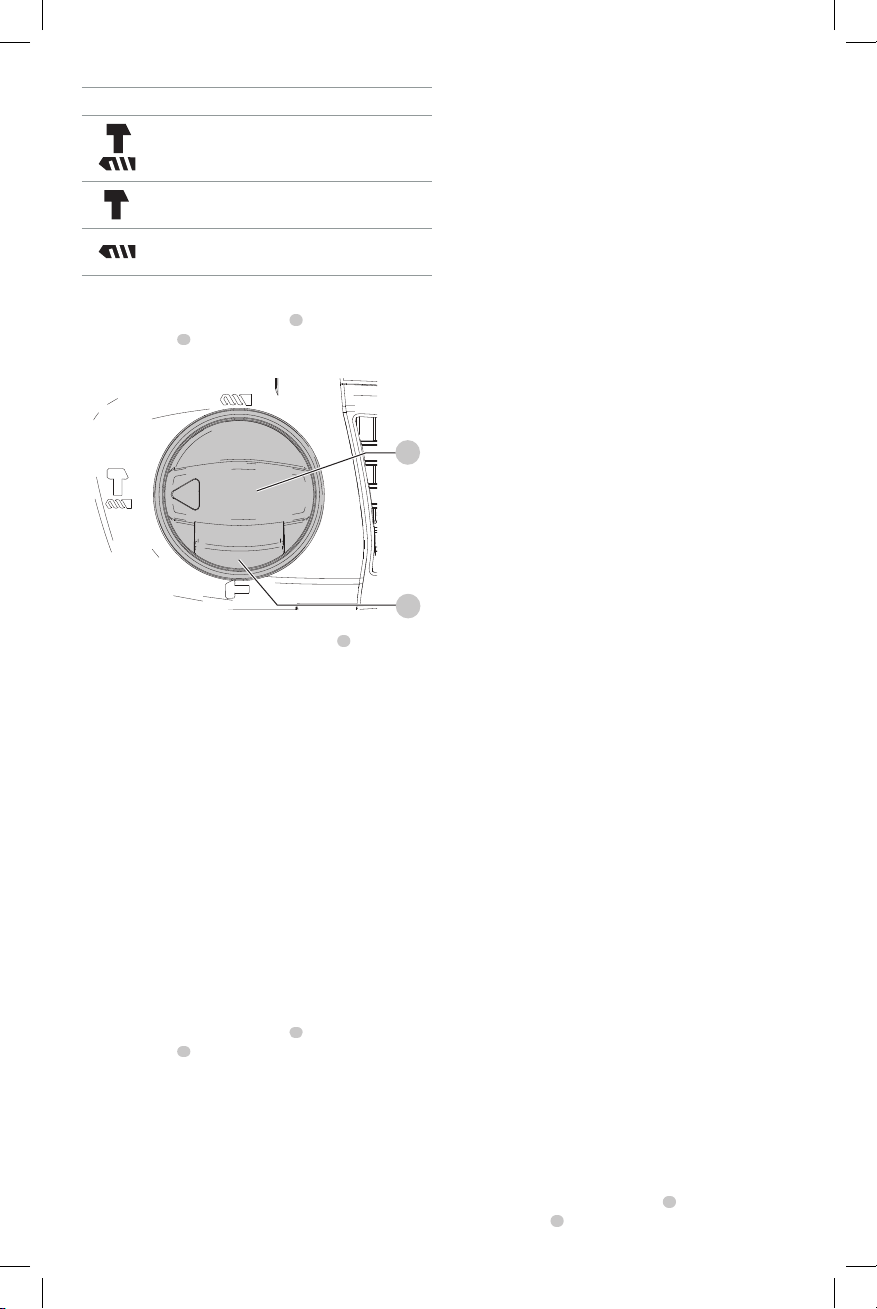

To Select an Operating Mode (Fig. I)

• Press the mode selector button

5

and rotate the mode

selector dial

4

so that the arrow points to the symbol

corresponding for the desiredmode.

Fig. I

4

5

NOTE: The arrow on the mode selector dial

4

must be

pointing at a mode symbol at all times. There are no

operable positions inbetween. It may be necessary to briefly

run the motor after having changed from 'hammering only'

to 'rotary' modes in order to align thegears or to postion

the chiselbit.

Drilling (Fig. I)

WARNING: To reduce the risk of personal injury,

ALWAYS operate the tool with the side handle

properly installed. Failure to do so may result in

the side handle slipping during tool operation and

subsequent loss of control. Hold tool with both hands

to maximizecontrol.

WARNING: TO REDUCE THE RISK OF PERSONAL

INJURY, ALWAYS ensure workpiece is anchored or

clamped firmly. If drilling thin material, use a wood

“back-up” block to prevent damage to thematerial.

NOTICE: If drilling thin material, use a wood

“back-up” block to prevent damage to thematerial.

1. Press the mode selector button

5

and rotate the mode

selector dial

4

to the drilling symbol.

2. Use sharp drill bits only. For wood, use twist bits,

spade bits, power auger bits or hole saws. For metal,

use high-speed steel twist drill bits or hole saws. Use a

cutting lubricant when drilling metals. The exceptions

are cast iron and brass which should be drilled dry. For

masonry, such as brick, cement, cinder block, etc., use

carbide-tipped bits rated for percussiondrilling.

3. Always apply pressure in a straight line with the bit. Use

enough pressure to keep drill biting, but do not push

hard enough to stall the motor or deflect thebit.

4. Hold tool firmly with both hands to control the twisting

action of the drill. If model is not equipped with side

handle, grip drill with one hand on the handle and one

hand on the batterypack.

WARNING: Drill may stall if overloaded causing a

sudden twist. Always expect the stall. Grip the drill

firmly to control the twisting action and avoidinjury.

5. IF DRILL STALLS, it is usually because it is being

overloaded or improperly used. RELEASE TRIGGER

IMMEDIATELY, remove drill bit from work, and

determine cause of stalling. DO NOT depress TRIGGER

ON AND OFF IN AN ATTEMPT TO START A STALLED

DRILL—THIS CAN DAMAGE THEDRILL.

6. To minimize stalling or breaking through the material,

reduce pressure on drill and ease the bit through the

last fractional part of thehole.

7. Keep the motor running when pulling the bit back out

of a drilled hole. This will help preventjamming.

8. With variable speed drills there is no need to center

punch the point to be drilled. Use a slow speed to start

the hole and accelerate by squeezing the trigger harder

when the hole is deep enough to drill without the bit

skippingout.

Drilling in Metal

A SDSPLUS to round shank adaptor chuck is required.

Ensure that tool is in Drilling mode. Start drilling with

slow speed and increase to full power while applying firm

pressure on the tool. A smooth even flow of metal chips

indicates the proper drilling rate. Use a cutting lubricant

when drilling metals. The exceptions are cast iron and brass

which should be drilleddry.

NOTE: Large (5/16" to 1/2" [7.9 mm to 12.7 mm]) holes

in steel can be made easier if a pilot hole (5/32" to 3/16"

[4mm to 4.8 mm]) is drilledfirst.

Drilling in Wood

A SDSPLUS to round shank adaptor chuck is required.

Ensure that tool is in Drilling mode. Start drilling with

slow speed and increase to full power while applying firm

pressure on the tool. Holes in wood can be made with the

same twist drills used for metal. These bits may overheat

unless pulled out frequently to clear chips from the flutes.

For larger holes, use spade bits, power auger bits, or hole

saws. Work that is apt to splinter should be backed up with

a block ofwood.

Drilling in Masonry

When drilling in masonry, use carbide-tipped bits rated for

percussion drilling and be certain that the bits are sharp.

Use a constant and firm force on the tool to drill most

effectively. A smooth, even flow of dust indicates the proper

drillingrate.

Hammerdrill Operation (Fig. I)

1. Press the mode selector button

5

and rotate the mode

selector dial

4

to the hammerdrilling symbol.

Loading ...

Loading ...

Loading ...