Loading ...

Loading ...

Loading ...

24 - INSTALLATION 91477A432/A

Connection to LPG

Use a pressure regulator and make the

connection on the gas cylinder following the

guidelines set out in the standards in force.

The supply pressure must comply with the values

indicated in the “Burner and nozzle

characteristics table”.

Room ventilation

The appliance should be installed in rooms that

have a permanent air supply in accordance

with the standards in force. The room where the

appliance is installed must have enough air flow

for the regular combustion of gas burners.

The appliance should be installed in rooms with

natural ventilation, as required by regulatory

standard AS/NZS5601.

When the job is complete, the installer must

issue a certificate of conformity.

Adaptation to different types of gas

In case of operation with other types of gas, the

burner nozzles must be changed and the

minimum flame adjusted on the gas cocks.

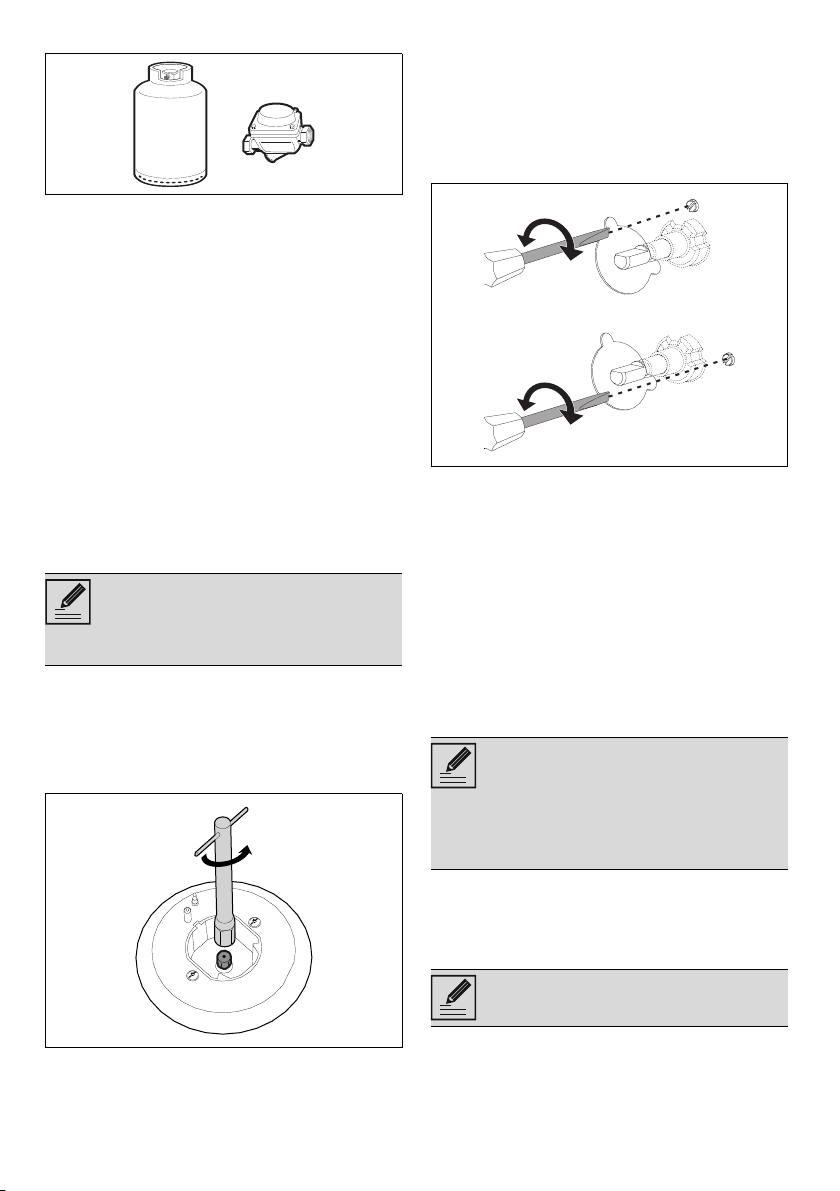

Replacing nozzles

1. Remove the pan supports, burner caps and

flame-spreader crowns to access the burner

cups.

2. Replace the nozzles using a 7-mm wrench

according to the type of gas to be used (see

the “Burner and nozzle characteristics

table”).

3. Replace the burners in their respective

housings.

Adjusting the minimum setting for natural gas

Light the burner and turn it to the minimum

position. Extract the gas cock knob and turn the

adjustment screw next to the gas cock spindle

(depending on the model) until the correct

minimum flame is achieved.

Refit the knob and verify that the burner flame is

stable. Turn the knob rapidly from the maximum

to the minimum setting: The flame should not go

out. Repeat the operation on all gas cocks.

Adjusting the minimum setting for LPG

Tighten the screw located at the side of the cock

spindle clockwise all the way.

Lubricating the gas cocks

Over time the gas cocks may become difficult to

turn and get blocked. Clean them internally and

replace the lubrication grease.

The maximum height of the highest point

of the pan support with respect to the

surface that supports the appliance is 12

mm.

Following adjustment to a gas other

than the one originally set in the factory,

replace the gas setting label on the

appliance with the one corresponding

to the new gas. The label is inserted

inside the nozzle pack (where present).

Lubrication of the gas cocks should be

performed by a specialised technician.

Loading ...

Loading ...

Loading ...