Loading ...

Loading ...

Loading ...

36 - INSTALLATION 91477A884/B

The nozzles not provided are available at Authorised Service Centres.

Electrical connection

General information

Check the mains characteristics against the data

indicated on the plate.

The identification plate bearing the technical

data, serial number and brand name is visibly

positioned on the appliance.

Do not remove this plate for any reason.

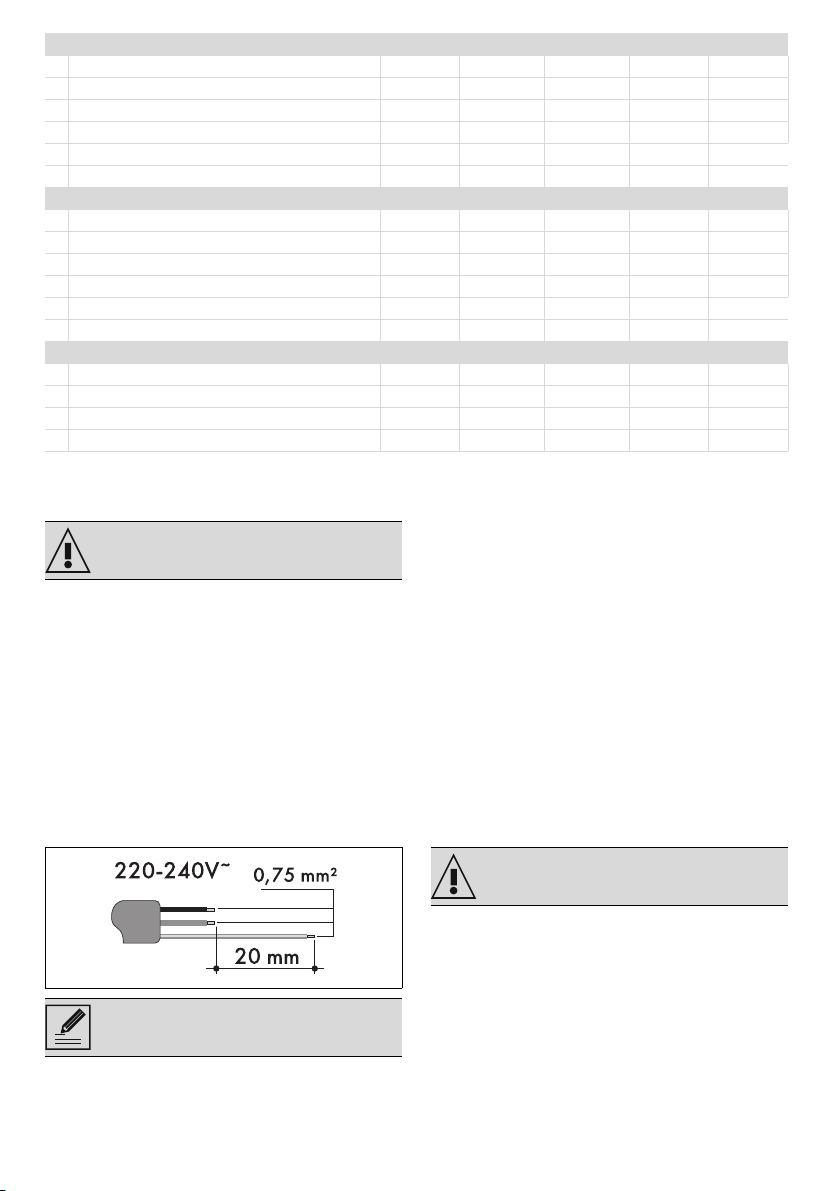

The appliance must be connected to ground

using a wire that is at least 20 mm longer than

the other wires.

The appliance can work in the following modes:

• 220-240 V 1N~

Fixed connection

Fit the power line with an all-pole circuit breaker

with a contact separation distance sufficient to

provide complete disconnection in category III

overvoltage conditions, pursuant to installation

regulations.

For the Australian/New Zealand market:

The circuit breaker incorporated in the fixed

connection must comply with AS/NZS 3000.

Connection with plug and socket

Make sure that the plug and socket are of the

same type.

Avoid using adapters, gang sockets or shunts as

these could cause overheating and a risk of

burns.

Section cut from the countertop

Safety instructions for positioning and

installation

• Installation can be carried out on various

materials such as masonry, metal, solid

wood or plastic laminated wood as long as

they are heat resistant (>90°C).

• Veneers, adhesives or plastic coatings on

adjacent furniture should be temperature-

resistant (>90°C), otherwise they might

warp over time.

• If the piece of furniture does not have the

required recess opening, either it will have

to be cut or masonry work carried out by a

5 LPG G30/31 - 30/37 mbar AUX SR RR R UR2

Rated heating capacity (kW) 1.00 1.70 2.60 2.90 4.00

Nozzle diameter (1/100 mm) 50 65 81 85 98

Pre-chamber (printed on nozzle) - - - - (S4)

Reduced flow rate (W) 400 500 800 800 1600

Rated flow rate G30 (g/h) 73 124 189 211 291

Rated flow rate G31 (g/h) 71 121 186 207 286

6 LPG G30/31 - 37 mbar AUX SR RR R UR2

Rated heating capacity (kW) 1.10 1.80 2.60 3.00 4.00

Nozzle diameter (1/100 mm) 50 65 75 81 92

Pre-chamber (printed on nozzle) - - - - (S4)

Reduced flow rate (W) 450 550 900 900 1800

Rated flow rate G30 (g/h) 80 131 189 218 291

Rated flow rate G31 (g/h) 79 129 186 214 286

7 Town gas G110 – 8 mbar AUX SR RR R UR2

Rated heating capacity (kW) 1.00 1.70 2.60 2.90 3.60

Nozzle diameter (1/100 mm) 145 185 240 260 340

Pre-chamber (printed on nozzle) /8 /2 /3 /3 0190

Reduced flow rate (W) 400 500 800 800 1400

See General safety instructions.

The values indicated refer to the cross-

section of the internal conductor.

See General safety instructions.

Loading ...

Loading ...