Loading ...

Loading ...

Loading ...

30

INSTALLATION

Check the appliance is electrically safe and gas sound when you have nished.

Connect the range to the gas supply

Shut o the main gas supply valve before disconnecting the

old range and leave it o until the new hookup has been

completed. Don’t forget to relight the pilot on other gas

appliances when you turn the gas back on.

Because hard piping restricts movement of the range, the

use of a CSA International-certied exible metal appliance

connector is recommended unless local codes require a hard-

piped connection.

Never use an old connector when installing a new range.

If the hard piping method is used, you must carefully align

the pipe; the range cannot be moved after the connection is

made.

To prevent gas leaks, put pipe joint compound on, or wrap

pipe thread tape with Teon* around, all male (external) pipe

threads.

A. Install a manual gas line shut-o valve in the gas line in

an easily accessed location outside of the range. Make

sure everyone operating the range knows where and

how to shut o the gas supply to the range.

B. Install a male ½’’ (1.5 cm) are union adapter to the ½’’

(1.5 cm) NPT internal thread elbow at inlet of regulator.

Use a backup wrench on the regulator tting to avoid

damage. When installing the range from the front,

remove the 90° elbow for easier installation.

C. Install male ½’’ (1.5 cm) or ¾’’ (2 cm) are union adapter

to the NPT internal thread of the manual shut-o valve,

taking care to backup the shut-o valve to keep it from

turning.

D. Connect exible metal appliance connector to the

adapter on the range. Position the range to permit

connection at the shut-o valve.

E. When all connections have been made, make sure

all range controls are in the o position and turn on

the main gas supply valve. Use a liquid leak detector

at all joints and connections to check for leaks in the

system. Use a product specically manufactured for

leak detection. Leak testing of the appliance shall

be conducted in accordance to the manufacturer’s

instructions.

DO NOT use a ame to check for gas leaks.

When using test pressures greater than ½ psig (3.5 kPa)

to pressure test the gas supply system of the residence,

disconnect the range and individual shut-o valve from

the gas supply piping. When using test pressures of ½ psig

(3.5 kPa) or less to test the gas supply system, simply

isolate the range from the gas supply system by closing the

individual shut-o valve.

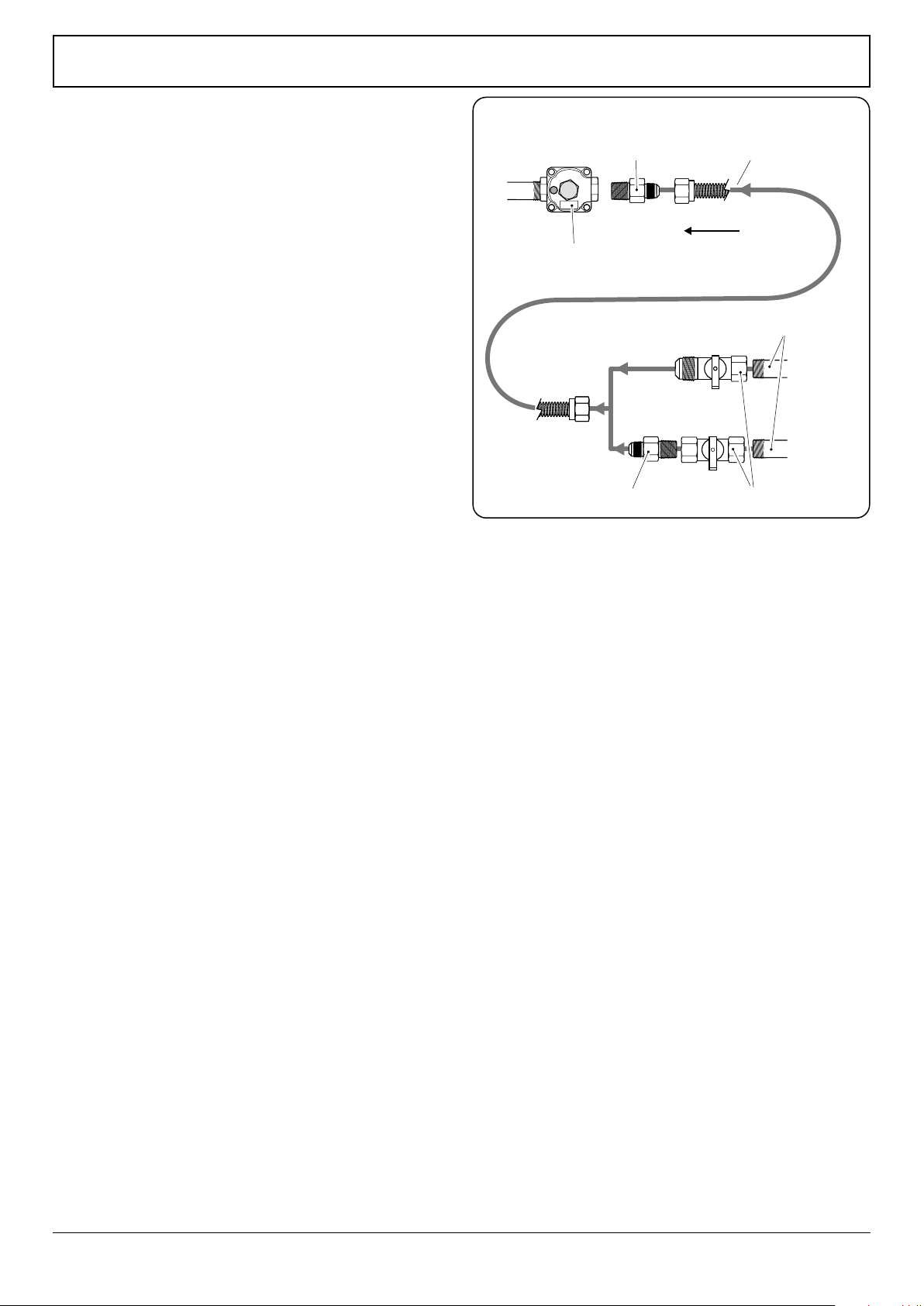

Flexible connector

Installer: Inform the consumer of the location of the gas

shut-o valve (Fig. 10.4).

ArtNo.140-0007 - US Gas connection reversed

½“ or ¾” gas pipe

Flexible connectorAdaptor

Appliance

gas inlet

Pressure regulator

Adaptor Gas shut-o valve

Gas supply

OR

Fig. 10.4

Loading ...

Loading ...

Loading ...