Loading ...

Loading ...

Loading ...

4

- All Other Markets:

NOTE:

(*) Measure burner operating pressure at manifold test point with two burners operating at the 'High

Flame' setting.

NAT, LPG & Butane Only - Operating pressure is ex-factory set and is not to be adjusted, apart from

when converting between gases, if required. (Refer to ‘Gas Conversion’ section for further details).

(**) TOWN GAS Only - Burner operating pressure is to be adjusted using the adjustable gas regulator

supplied.

Refer to the ‘Gas Conversion and Specifications’ section in this manual for further details.

Cabinet Models;

Gas supply connection point is located at rear of appliance, approximately 130mm from right hand side and

655mm from floor. It is reached from beneath the appliance. (Refer to ‘Dimensions’ drawings).

Benchtop Models;

Gas supply connection point is located at rear of appliance, approximately 130mm from right hand side and

60mm from floor. It is reached from beneath the appliance. (Refer to ‘Dimensions’ drawings).

Connection is ¾" BSP male thread (for all models).

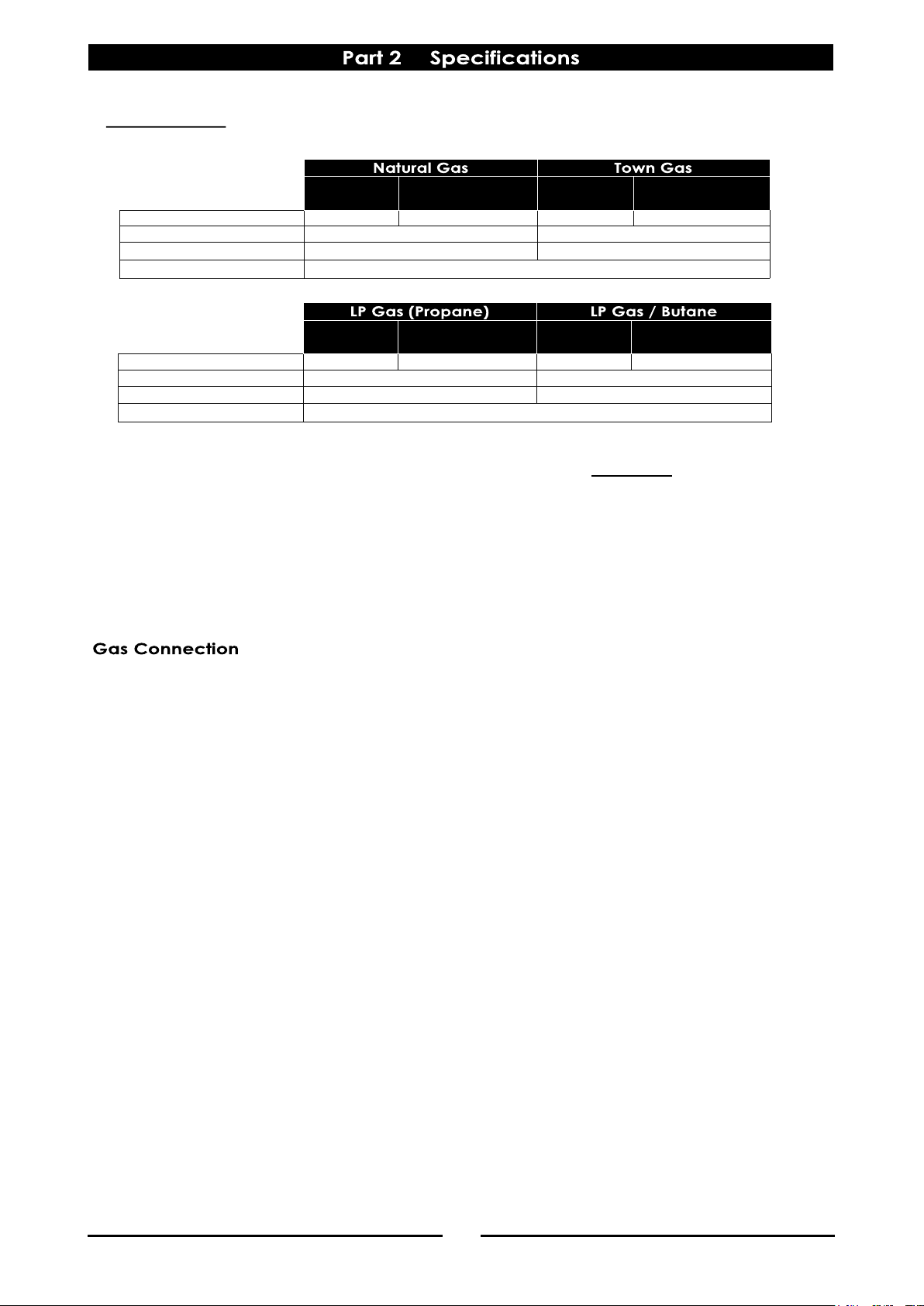

Open Burner

(each)

Griddle

(each 300mm section)

Open Burner

(each)

Griddle

(each 300mm section)

Input Rate (N.H.G.C.)

22 MJ/hr 20 MJ/hr 22 MJ/hr 20 MJ/hr

Supply Pressure

2.75 - 4.50 kPa 2.75 - 4.50 kPa

Burner Operating Pressure (*)

2.6 kPa 2.6 kPa

Gas Connection

¾” BSP Male

Open Burner

(each)

Griddle

(each 300mm section)

Open Burner

(each)

Griddle

(each 300mm section)

Input Rate (N.H.G.C.)

22 MJ/hr 20 MJ/hr 22 MJ/hr 20 MJ/hr

Supply Pressure

1.13 - 3.40 kPa 0.75 - 1.50 kPa

Burner Operating Pressure (*)

1.0 kPa 0.63 kPa

Gas Connection

¾” BSP Male

Loading ...

Loading ...

Loading ...