Loading ...

Loading ...

Loading ...

8. Reinstallorificeandin-linefilterintonozzleextension.

DONOTovertightenorificewithallenwrench.

9. Reconnectnozzleextensiontospraygun.

10.Makesuregardenhoseisconnectedtowaterinlet.

Checkthathighpressurehoseisconnectedtospraygun

andpump.Turnonwater.

11.Engagetriggerlockonspraygunandstartengine

followinginstructions"HowtoStartYourPressure

Washer".

12.Testpressurewasherbyoperatingnozzleinhighand

lowpositions.

O-Ring Maintenance

Purchasean O-Ring Repair Kit at your local Searsor by calling

1-808-4-MY-HOME(469-4663) or onlineat www.sears.com.It

is not includedwith the pressurewasher.This kit includes

replacemento-rings, rubberwasherandwaterinlet filter. Referto

the instructionsheetprovidedin the kit to serviceyour unit's

o-rings.

WARHIHG

The high pressure stream of water that this

_ quipment produces can cut through skin and its

underlying tissues, leadingto serious injury and

)ossible amputation.

* NEVERrepairleakingconnectionswith sealantof anykind.

Replaceo-ringor seal.

Pump Oil Maintenance

DONOTattempt any oil maintenanceon this pump. This

model does not require any pump oil maintenance. The pump

is pre-lubricated and sealed from the factory, requiring no

additional lubrication for the life of the pump.

ENGINEMAINTENANCE

WARHJHG

_' Unintentional sparking can result in fire or

_¢ electric shock.

WHENADJUSTINGORMAKINGREPAIRSTO YOUR

PRESSUREWASHER

* Disconnectthe spark plugwire from the sparkplugand place

the wire whereit cannotcontactsparkplug.

WHENTESTINGFORENGINESPARK

* Useapprovedsparkplugtester.

* DONOTcheckfor sparkwith sparkplugremoved.

Oil

OiJRecommendations

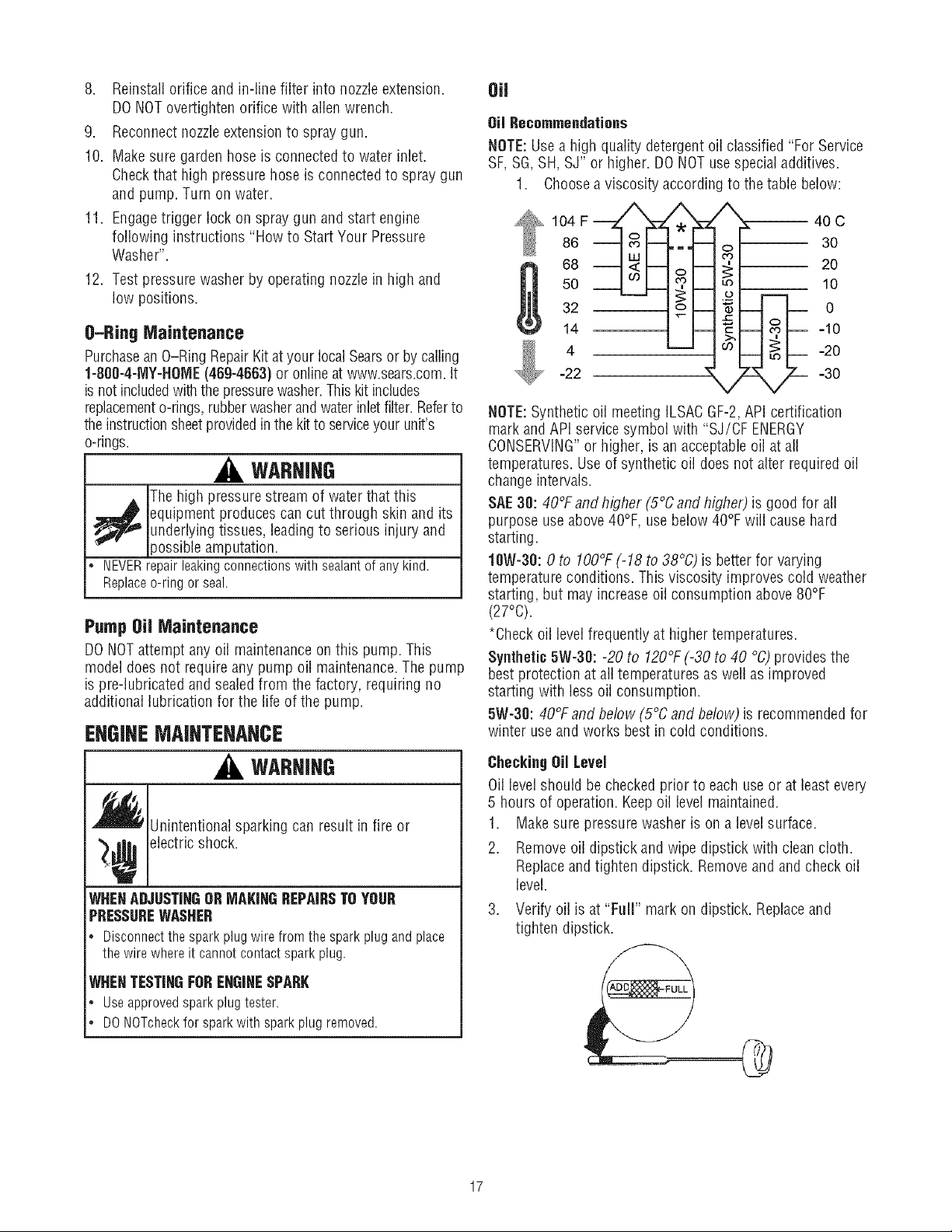

NOTE:Use a high quality detergent oil classified "For Service

SF,SG, SH, SJ" or higher. DO NOTuse special additives.

1. Choosea viscosity according to the table below:

104 F _====_ _&==__ ' &==Z

86 _..--

68

50 o

32

14

4

-22

40 C

o 30

20

10

_ 0

-10

-20

-30

NOTE:Synthetic oil meeting ILSAC GF-2,API certification

mark and API service symbol with "SJ/CF ENERGY

CONSERVING"or higher, is an acceptableoil at all

temperatures. Use of synthetic oil does not alter required oil

change intervals.

SAE30: 40°F and higher (5°C and higher) is good for all

purpose use above 40°F, use below 40°F will causehard

starting.

10W-30:0 to IO0°F (-18 to 38°C) is better for varying

temperature conditions. This viscosity improves cold weather

starting, but may increaseoil consumption above 80°F

(27°C).

*Check oil level frequently at higher temperatures.

Synthetic 5W-30:-20 to 120°F(-30 to 40 °C) provides the

best protection at all temperatures as well as improved

starting with less oil consumption.

5W-30: 40°F and below (5°C and below) is recommended for

winter use and works best in cold conditions.

CheckingOil Level

Oil level should be checked prior to each use or at least every

5 hours of operation. Keepoil level maintained.

1. Makesure pressure washer is on a level surface.

2. Remove oil dipstick and wipe dipstick with clean cloth.

Replaceand tighten dipstick. Removeand and check oil

level.

3. Verify oil is at "Full" mark on dipstick. Replaceand

tighten dipstick.

/p--\

@

17

Loading ...

Loading ...

Loading ...