Loading ...

Loading ...

Loading ...

5

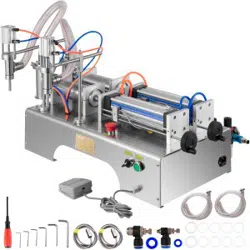

5、The speed of the upper and lower valve switches of the two filling

heads (18) of the double-head liquid filling machine mainly adjusts the two

throttle valves (21) on the thin cylinder (20) on the filling head;

6、The speed of the upper and lower valve opening and closing of the two

slap filling head (18) of the double-head liquid filling machine is not

necessarily the same, which is determined according to the experience of the

field production and operator;

7、The filling accuracy mainly depends on the wear of the cylinder piston

(23) or the silicone O-ring (24) on the piston, as well as the wear of all

the O-rings and all flat seals on it;

8、Minimize the air in the feeding leather tube as much as possible.

5、Point and automatic operation

The jog and automatic selection switch (10) is mainly set for debugging

or measurement. Whenever the new machine is commissioned, or the product is

changed, or the filling volume is changed, or the equipment is cleaned, it

is recommended to use the jog gear to debug. When the commissioning is

completed and the product filling volume is normal, the automatic gear works.

You can switch between jog and automatic without shutting down.

6、Use of emergency stop switch

The safety switch is also called emergency stop switch (25). In normal

work, the safety switch is turned off. When the material is lost due to

improper operation, the safety switch can be pressed to avoid material waste

and keep the workshop clean.

7、Daily maintenance1.

1、In order to keep the fuse tube frame (27) smooth and clean, do not

scrape its surface with sharp or hard sharp tools. If there is any stain,

wipe it with alcohol;

2、The cylinder (26) has been lubricated at the factory. Do not disassemble

the cylinder or add any lubricant.

3、Stainless steel tee (1), material tank (22), filling head (18), O-ring,

seal ring, etc. can be easily removed and washed.

4、When cleaning is needed, turn on the machine and let the machine work

automatically until cleaning. It is best to use hot water for cleaning.

5、If the machine is not used for a long time, the stainless steel tee,

material tank, filling head, 0-ring, sealing ring and other parts in contact

with the material can be removed and cleaned to prevent the material from

drying and corrosion. For future use.

Filling machine

Loading ...

Loading ...

Loading ...