Loading ...

Loading ...

Loading ...

2

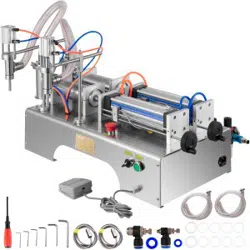

1.3 Performance: The semi-automatic piston filling machine produced by

our company is based on the company's filling machine series, introducing

foreign advanced filling machine technology, and carried out a series of

transformations and innovations. Its structure is simpler and more reasonable.

Higher accuracy, easier cleaning, and easier operation. The contact areas with

the material are made of 304 stainless steel, which meets the requirements of

GMP. The sealing parts are made of PTFE and silicone materials. They have

corrosion resistance, aging resistance, high temperature resistance, and

sealing. Good and other advantages, ideal for filling equipment in food,

pharmaceutical, chemical, daily chemical, oil, pesticide and other industries。

2 、 C a u t i o n s an d fa c t o r s a f f e c t e d b y wo r k

Safety Precautions:This series of filling machine is only suitable for

filling liquid, low concentration paste can not be used for other purposes.

To ensure safe production, please read the following precautions carefully:

1. Use a power supply and air source that conforms to the requirements of

this machine (see the technical parameters of the machine in this book for

details). The stability of the air source must be maintained under continuous

working conditions.

2. Before disassembling, washing or repairing this machine, please be sure

to turn off the air source and power supply first.

3. The rear half of the machine (near the control buttons) and the lower part

of the machine frame are equipped with electrical control components. Under

no circumstances should the body be washed directly with water, otherwise there

will be danger of electric shock and damage to the electrical control

components.

4. After the power switch is turned off, there is still voltage in some

circuits in the electrical control of this machine. When repairing the control

circuit, please be sure to unplug the power cord.

5. Do not keep your eyes close to the filling head during work, pay attention

to personal safety.

6. Do not put your hand on the central axis of the cylinder during the work

process, pay attention to pinching your hands.

7. Before using materials for filling, it is best to clean the machine with

detergent first, and then clean it with clean water, so as to avoid oil stains

or foreign materials and materials mixing, which will lead to waste of materials

and damage to the machine.

Cover the hopper of the paste filling machine when it is not working to prevent

dust or other debris from entering the hopper, resulting in wasted materials

and damage to the machine.

Affected by the following factors at work

1.The factors that affect the filling accuracy are: the stability of the

compressed air, the uniformity of the material, the filling speed, etc.

Filling machine

Loading ...

Loading ...

Loading ...