Loading ...

Loading ...

Loading ...

j Installation Instructions Split System Condensers J

Installing Refrigerant Lines

Component Matches

Check to see that you have the proper system compo-

nents. APPROVED MATCHED SYSTEM COMPON ENTS

MUST BE USED. Refer to the Sales Specification Sheet

or Split System Summary for match data and orifice

sizes,

The outdoor units are shipped with a refrigerant charge to

match the indoor unit and 15 ft. (4.5m) of refrigerant line. If

shorter or longer lines are used, the charge will have to be

adjusted.

TOTAL LENGTH OF REFRIGERANT LINES MUST NOT

EXCEED 50 ft. WITH A MAXIMUM VERTICAL SEPARA-

TION OF 40 ft. BETWEEN THE OUTDOOR AND IN-

DOOR UNITS.

PLEASE! UNDER NO CIRCUMSTANCES LEAVE THE

LINES OPEN TO THE ATMOSPHERE FOR ANY

PERIOD OF TIME,

Be extra careful with sharp bends. This tubing can "kink"

very easily, and if this occurs, the entire tube length will

have to be replaced. Extra care at this time will eliminate

future service problems.

Suspension And Installation Of

Refrigeration Lines

DO NOT fasten liquid or suction lines in direct contact with

the floor or ceiling joist. Use an insulated or suspension

type of hanger. Keep both lines separate, and insulate the

suction line. Both lines should be insulated in long runs in

an attic or underground in a raceway.

Restrictor Orifice

Some indoor matches use a restrictor orifice in the fitting at

the indoor coil. Some matches may require a different ori-

fice for proper system performance and it must be changed

before the refrigerant lines are connected.

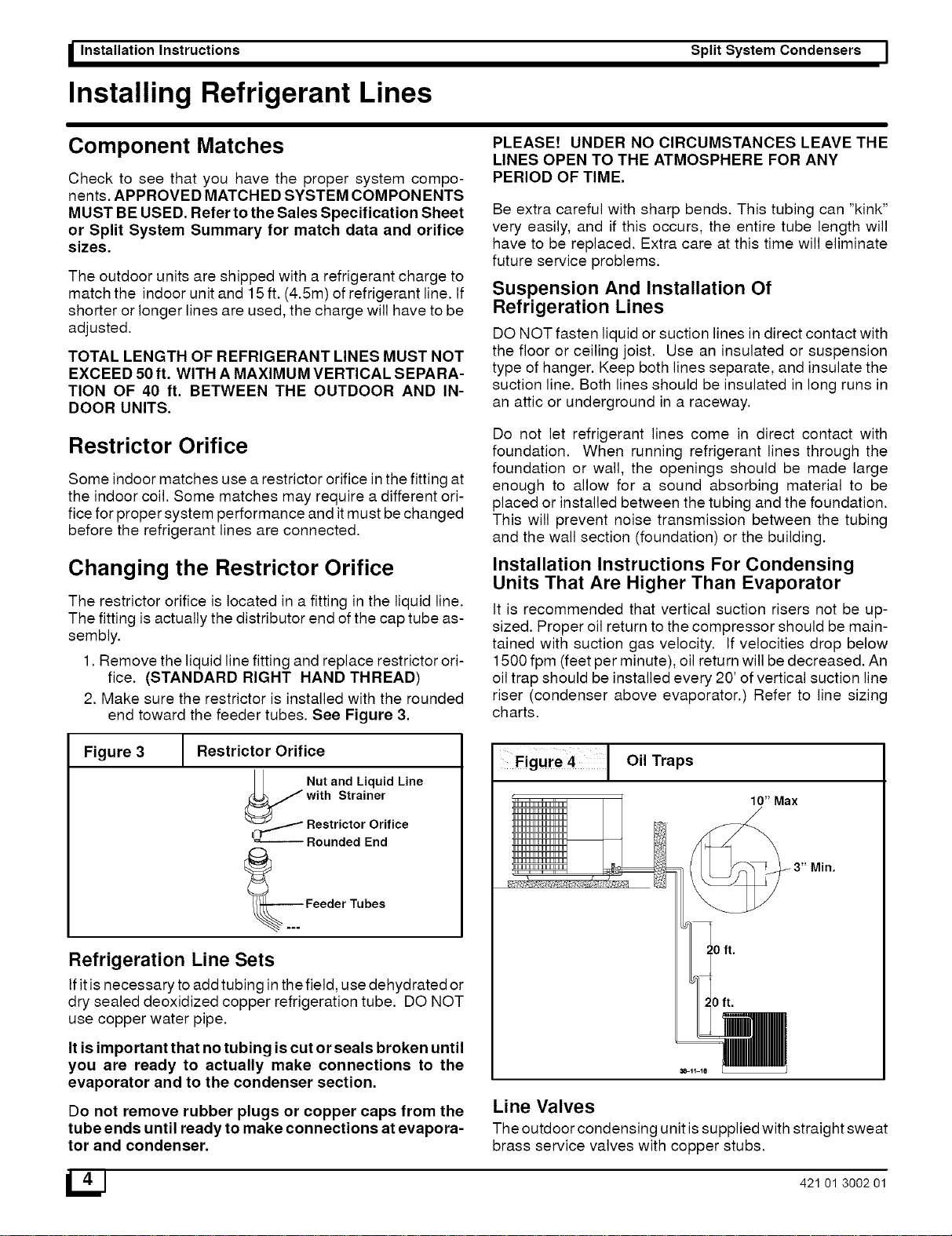

Changing the Restrictor Orifice

The restrictor orifice is located in a fitting in the liquid line.

The fitting is actually the distributor end of the cap tube as-

sembly.

1. Remove the liquid line fitting and replace restrictor ori-

fice. (STANDARD RIGHT HAND THREAD)

2. Make sure the restrictor is installed with the rounded

end toward the feeder tubes. See Figure 3.

Figure 3 J

Restrictor Orifice

Nut and Liquid Line

with Strainer

! RRestr 'dC_drEOd''ce

_Feeder Tubes

Refrigeration Line Sets

Ifit is necessary toadd tubing in the field, use dehydrated or

dry sealed deoxidized copper refrigeration tube. DO NOT

use copper water pipe.

It is important that no tubing iscut or seals broken until

you are ready to actually make connections to the

evaporator and to the condenser section.

Do not remove rubber plugs or copper caps from the

tube ends until ready to make connections at evapora-

tor and condenser.

Do not let refrigerant lines come in direct contact with

foundation. When running refrigerant lines through the

foundation or wall, the openings should be made large

enough to allow for a sound absorbing material to be

placed or installed between the tubing and the foundation.

This will prevent noise transmission between the tubing

and the wall section (foundation) or the building.

Installation Instructions For Condensing

Units That Are Higher Than Evaporator

It is recommended that vertical suction risers not be up-

sized. Proper oil return to the compressor should be main-

tained with suction gas velocity. If velocities drop below

1500 fpm (feet per minute), oil return will be decreased. An

oil trap should be installed every 20' of vertical suction line

riser (condenser above evaporator.) Refer to line sizing

charts.

Figure 4 Oil Traps

10" Max

Min.

_8-11-1e

Line Valves

The outdoor condensing unit issupplied with straight sweat

brass service valves with copper stubs.

_J 421 01 3002 01

Loading ...

Loading ...

Loading ...