Loading ...

Loading ...

Loading ...

English

■English 7

Refrigerant Piping Work

Seetheinstallationmanualsuppliedwiththeoutdoorunit.

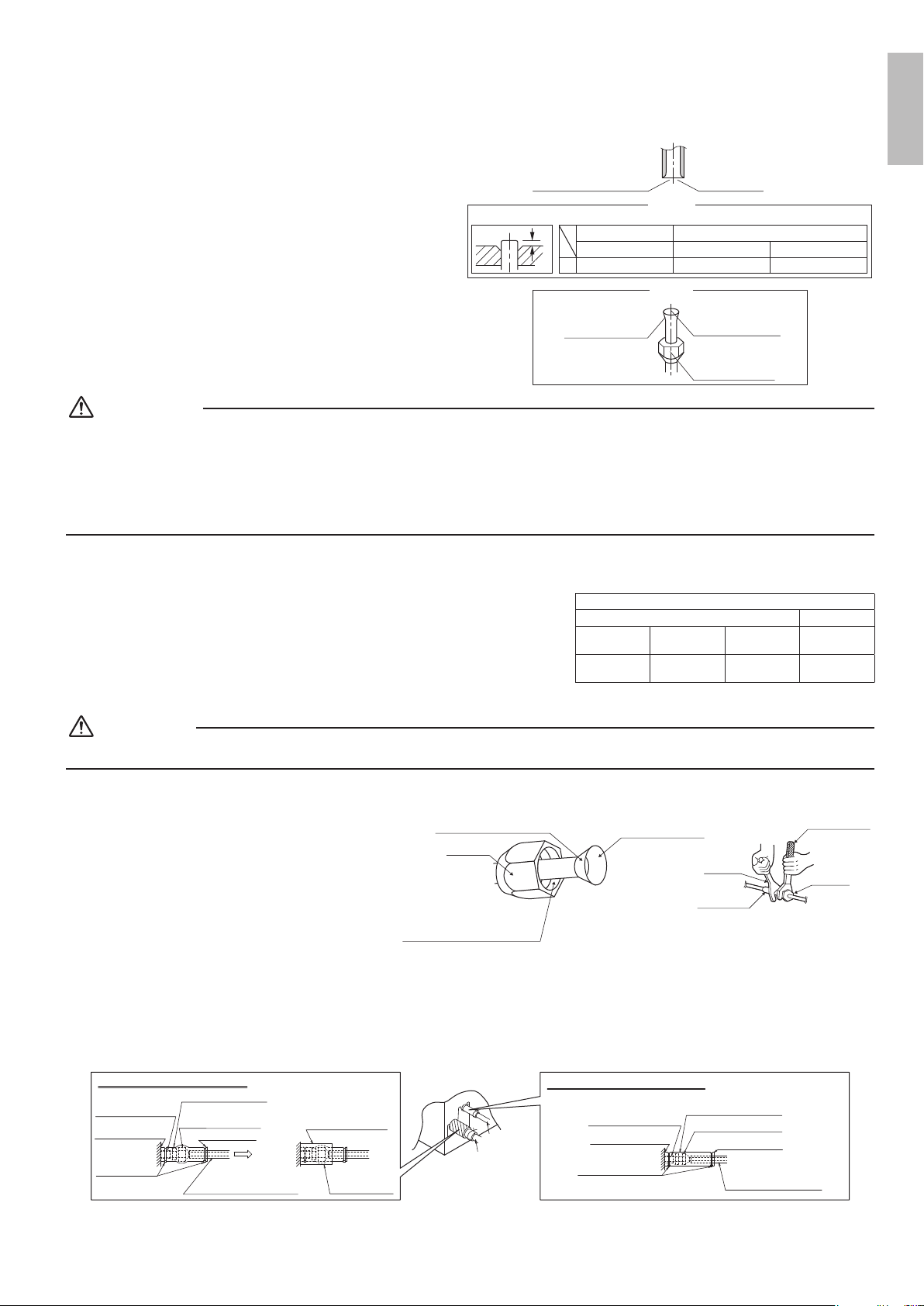

1. Flaring the pipe end

1)Cutthepipeendwithapipecutter.

2)Removeburrswiththecutsurfacefacing

downwardsothatthechipsdonotenterthepipe.

3)Putthearenutonthepipe.

4)Flarethepipe.

5)Checkthatthearingisproperlymade.

A

A

(Cut exactly at right angles.) Remove burrs

Flare’s inner surface

must be flaw-free.

The pipe end must

be evenly flared in a

perfect circle.

Make sure that the

flare nut is fitted.

Check

0-0.02in (0-0.5mm)

0.04-0.06in (1.0-1.5mm) 0.06-0.08in (1.5-2.0mm)

Set exactly at the position shown below.

Clutch-type

Flare tool for R410A

Clutch-type (Rigid-type)

Wing-nut type (Imperial-type)

Conventional flare tool

Flaring

Die

WARNING

•Donotusemineraloilonaredpart.

•Preventmineraloilfromgettingintothesystemasthiswouldreducethelifetimeoftheunits.

•Neverusepipingwhichhasbeenusedforpreviousinstallations.Onlyusepartswhicharedeliveredwiththeunit.

•NeverinstalladriertothisR410Aunitinordertoguaranteeitslifetime.

•Thedryingmaterialmaydissolveanddamagethesystem.

Incompletearingmaycauserefrigerantgasleakage.

2. Refrigerant piping

1)Topreventgasleakage,applyrefrigerationmachineoiltotheinner

surfaceoftheare.(UserefrigerationoilforR410A)

2)Alignthecentersofbotharesandtightenthearenuts3or4turns

byhand.Thentightenthemfullywiththetorquewrenches.

•Usetorquewrencheswhentighteningthearenutstoprevent

damagetothearenutsandescapinggas.

Flarenuttighteningtorque

Gasside Liquidside

3/8inch

(9.5mm)

1/2inch

(12.7mm)

5/8inch

(15.9mm)

1/4inch

(6.4mm)

24.1-29.4ft•lbf

(32.7-39.9N•m)

36.5-44.5ft•lbf

(49.5-60.3N•m)

45.6-55.6ft•lbf

(61.8-75.4N•m)

10.4-12.7ft•lbf

(14.2-17.2N•m)

CAUTION

•Overtightening may damage the are and cause leaks.

3) After the work is nished, make sure to

check that there is no gas leak.

Torque wrench

Piping union

Flare nut

Spanner

Do not apply refrigeration

oil to the outer surface.

Flare nut

Apply refrigeration

oil to the inner

surface of the flare.

Do not apply refrigeration oil to

the flare nut to avoid tightening

with excessive torque.

4) After checking for gas leaks, be sure to insulate the pipe connections.

•Insulateusingtheinsulationforttingincludedwiththeliquidandgaspipes.Besides,makesuretheinsulationfortting

ontheliquidandgaspipinghasitsseamsfacingup.

(Tightenbothedgeswithclamp.)

•Forthegaspiping,wrapthemediumsealingpadovertheinsulationfortting(arenutpart).

Gas pipe

Liquid pipe

Piping insulation

material (main unit)

Attach to base

Flare nut connection

Turn seams up

Insulation for fitting

(accessory)

Clamp

Piping insulation material

(Field supplied)

Gas Piping Insulation Procedure

(accessory)

Main unit

Clamp (accessory)

Flare nut connection

Turn seams up

Piping insulation material

(Field supplied)

Piping insulation

material (main unit)

Attach to base

Main unit

Insulation for fitting

(accessory)

Liquid Piping Insulation Procedure

Small sealing pad

Measure the length of the gas

pipe as you will have to cover

it with the sealing tape.

(accessory)

Wrap the sealing

tape around the

gas pipe.

Main unit

01_EN_3P297301-4D.indd 7 5/8/2017 5:10:23 PM

Loading ...

Loading ...

Loading ...