Loading ...

Loading ...

Loading ...

WRONG

• i

WRONG

I

FIG. 4

RIGHT

I 10° tO 15°

REMOVING DISC

TURN OFF AND UNPLUG TOOL

Using a cloth or glove to protect your hand, turn the disc assembly

counter-clockwise to remove it from the tool spindle. Hold the spindle

in place by engaging the Lock Pin.

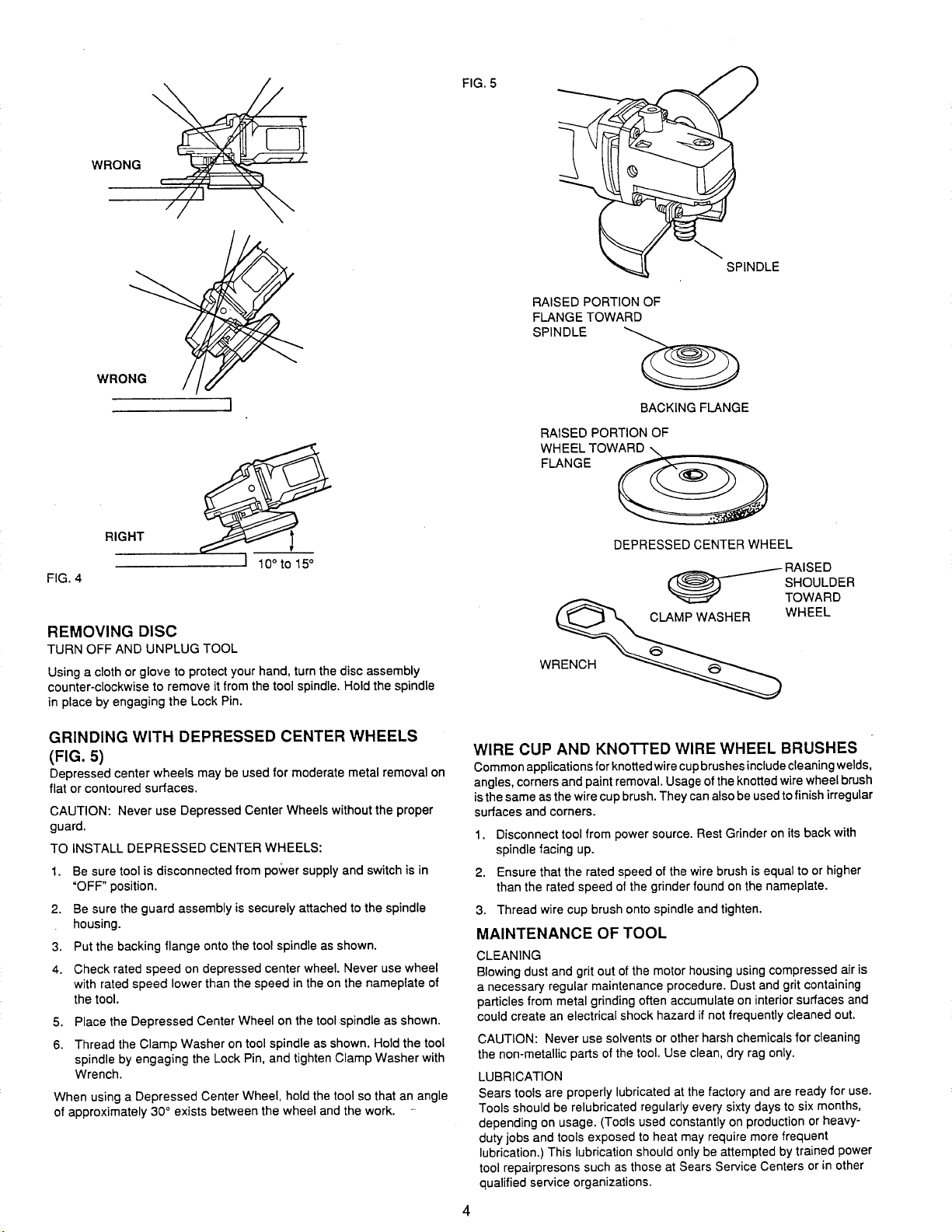

FIG. 5

LE

RAISED PORTION OF

FLANGE TOWARD

SPINDLE

BACKING FLANGE

RAISED PORTION OF

WHEEL TOWARD

FLANGE

DEPRESSED CENTER WHEEL

_--.-RAISED

_ SHOULDER

TOWARD

SHER WHEEL

WRENCH

GRINDING WITH DEPRESSED CENTER WHEELS

(FIG. 5)

Depressed center wheels may be used for moderate metal removal on

flat or contoured surfaces.

CAUTION: Never use Depressed Center Wheels without the proper

guard.

TO INSTALL DEPRESSED CENTER WHEELS:

1. Be sure tool is disconnected from power supply and switch is in

"OFF" position.

2. Be sure the guard assembly is securely attached to the spindle

housing.

3. Put the backing flange onto the tool spindle as shown.

4. Check rated speed on depressed center wheel. Never use wheel

with rated speed lower than the speed in the on the nameplate of

the tool.

5. Place the Depressed Center Wheel on the tool spindle as shown.

6. Thread the Clamp Washer on tool spindle as shown. Hold the tool

spindle by engaging the Lock Pin, and tighten Clamp Washer with

Wrench.

When using a Depressed Center Wheel, hold the tool so that an angle

of approximately 30° exists between the wheel and the work. -

WIRE CUP AND KNOTTED WIRE WHEEL BRUSHES

Commonapplications forknottedwirecupbrushesincludecleaningwelds,

angles,cornersandpaintremoval.Usageoftheknottedwirewheelbrush

isthesameas thewirecupbrush.Theycanalsobeusedtofinish irregular

surfaces andcorners.

1. Disconnect tool from power source. Rest Grinder on its back with

spindle facing up.

2. Ensure that the rated speed of the wire brush is equal to or higher

than the rated speed of the grinder found on the nameplate.

3. Thread wire cup brush onto spindle and tighten.

MAINTENANCE OF TOOL

CLEANING

Blowing dust and grit out of the motor housing using compressed air is

a necessary regular maintenance procedure. Dust and grit containing

particles from metal grinding often accumulate on interior surfaces and

could create an electrical shock hazard if not frequently cleaned out.

CAUTION: Never use solvents or other harsh chemicals for cleaning

the non-metallic parts of the tool. Use clean, dry rag only.

LUBRICATION

Sears tools are properly lubricated at the factory and are ready for use.

Tools should be relubricated regularly every sixty days to six months,

depending on usage. (Tools used constantly on production or heavy-

duty jobs and tools exposed to heat may require more frequent

lubrication.) This lubrication should only be attempted by trained power

tool repairpresons such as those at Sears Service Centers or in other

qualified service organizations.

Loading ...

Loading ...

Loading ...