Loading ...

Loading ...

19. OUTDOOR USE EXTENSION CORDS. When tool is used out-

doors, use only extension cords intended for use outdoors and so

marked.

20. STAY ALERT. Watch what you are doing. Use common sense. Do

not operate tool when you are tired.

21. CHECK DAMAGED PARTS. Before further use of the tool, a

guard or other part that is damaged should be carefully checked to

determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorized service

center unless otherwise indicated elsewhere in this instruction

manual. Have defective switches replaced by authorized service

center. Do not use tool if switch does not turn it on and off.

ADDITIONAL SAFETY INSTRUCTIONS FOR GRINDERS

1.

2.

3.

ALWAYS WEAR EYE PROTECTION.

KEEP GUARDS IN PLACE.

Use only grinding wheels having a maximum operating speed at

least highas "No Load RPM" marked on the tool'snameplate.

4. Before using, inspect recommended accessoryfor cracksor

flaws. If such a crack or flaw isevident, discard the accessory.

The accessory should also be inspectedwhenever you think the

tool may have been dropped.

5. When starting the tool (with a new or replacement wheel installed)

hold the tool in a well protected area and let it run for one minute.

If the wheel has an undetected crack or flaw, it should burst in less

than one minute. Never start the tool with a person in line with the

wheel. This includes the operator.

6. In operation, avoid bouncing the wheel or giving it rough treat-

ment. If this occurs, stop the tool and inspect the wheel.

7. ALWAYS USE GUARDS with depressed center wheels or flaring

cup grinding wheels.

8. Clean your tool out periodically.

9. CAUTION: Some wood contains preservatives such as copper

chromium arsenate (CCA) which can be toxic. When sanding

these materials extra care should be taken to avoid inhalation and

minimize skin contact.

SAVE THESE INSTRUCTIONS

SWITCH OPERATION (FIG. 1)

To start the grinder push the Switch Lock-Off Button forward and squeeze

the trigger switch. To turn the tool off, release the switch.

To lock the switch on for continuous operation, depress the trigger switch

and hold while you push in the Lock-On button at the end of the handle

shown in Figure 1. Hold the Lock-On button in as you release the trigger

switch. To turn the tool off from a locked on position, squeeze and release

the trigger switch once.

DO NOT STORE THE TOOL WITH THE SWITCH LOCKED ON... To do

so will cause the tool to start immediately the next time it is plugged in.

Damage or personal injury may result.

LOCK-ON BUTTON

©

©

FIG. 1

\

SWITCH

TRIGGER LOCK-OFF

SWITCH BU]-I'ON

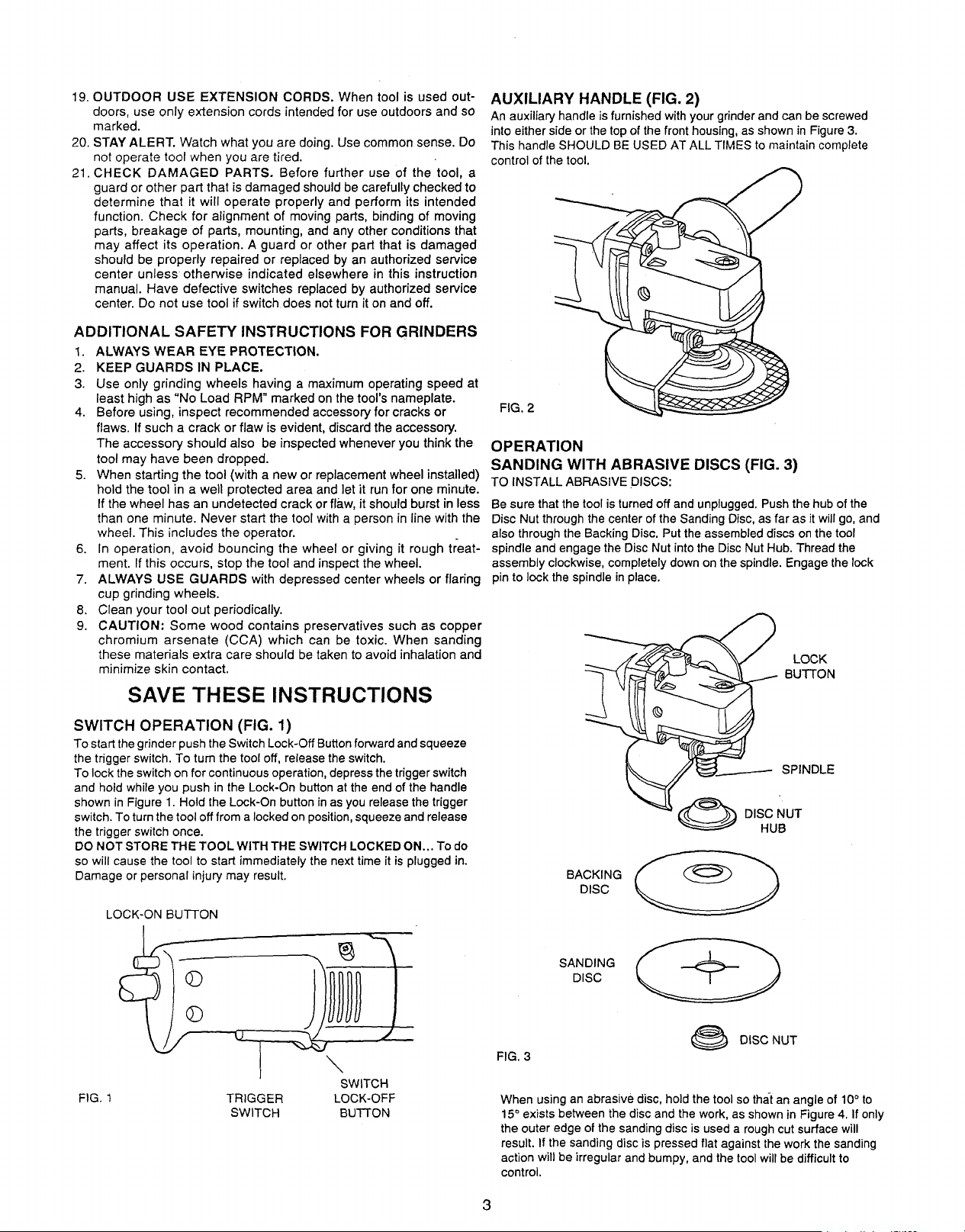

AUXILIARY HANDLE (FIG. 2)

An auxiliary handle is furnished with your grinder and can be screwed

into either side or the top of the front housing, as shown in Figure 3.

This handle SHOULD BE USED AT ALL TIMES to maintain complete

control of the tool.

FIG. 2

OPERATION

SANDING WITH ABRASIVE DISCS (FIG. 3)

TO INSTALL ABRASIVE DISCS:

Be sure that the tool is turned off and unplugged. Push the hub of the

Disc Nut through the center of the Sanding Disc, as far as it will go, and

also through the Backing Disc. Put the assembled discs on the tool

spindle and engage the Disc Nut into the Disc Nut Hub. Thread the

assembly clockwise, completely down on the spindle. Engage the lock

pin to lock the spindle in place.

FIG. 3

BACKING

DISC

SANDING

DISC

(_ DISC NUT

When using an abrasive disc, hold the tool so that an angle of 10° to

15° exists between the disc and the work, as shown in Figure 4. If only

the outer edge of the sanding disc is used a rough cut surface will

result. If the sanding disc is pressed flat against the work the sanding

action will be irregular and bumpy, and the tool will be difficult to

control.

3

Loading ...

Loading ...

Loading ...