Loading ...

Loading ...

Loading ...

13

English

to conduct a calibration check using a distance no shorter

than the distance of the applications for which the tool will

to the right to

7

.

and

. Always mark the center of the

Measure the distance between each set of marked lines

). If the measurement is

greater than the values shown below, the laser must be

Allowable Distance Between

Allowable Distance Between

Checking 90º accuracy requires an open floor area at least 33'

x 18' (10m x 5m). Refer to Figure O for the position of the

laser at each step and for the location of the marks made at

each step. Always mark the center of the beam's thickness.

Place the laser on a smooth, flat, stable surface that is level in

to the right to

b

O1).

7. Mark a location

e

along the front vertical beam at least

14' (4m) away from the unit (FigureO2).

8. Rotate the laser 90º so the side vertical beam now passes

through

b

and

e

(FigureO3).

9. Directly above or below

a

, mark

f

along the front

verticalbeam.

10. Measure the distance between

a

and

f

If the

measurement is greater than the values shown

below, the laser must be serviced at an authorized

servicecenter.

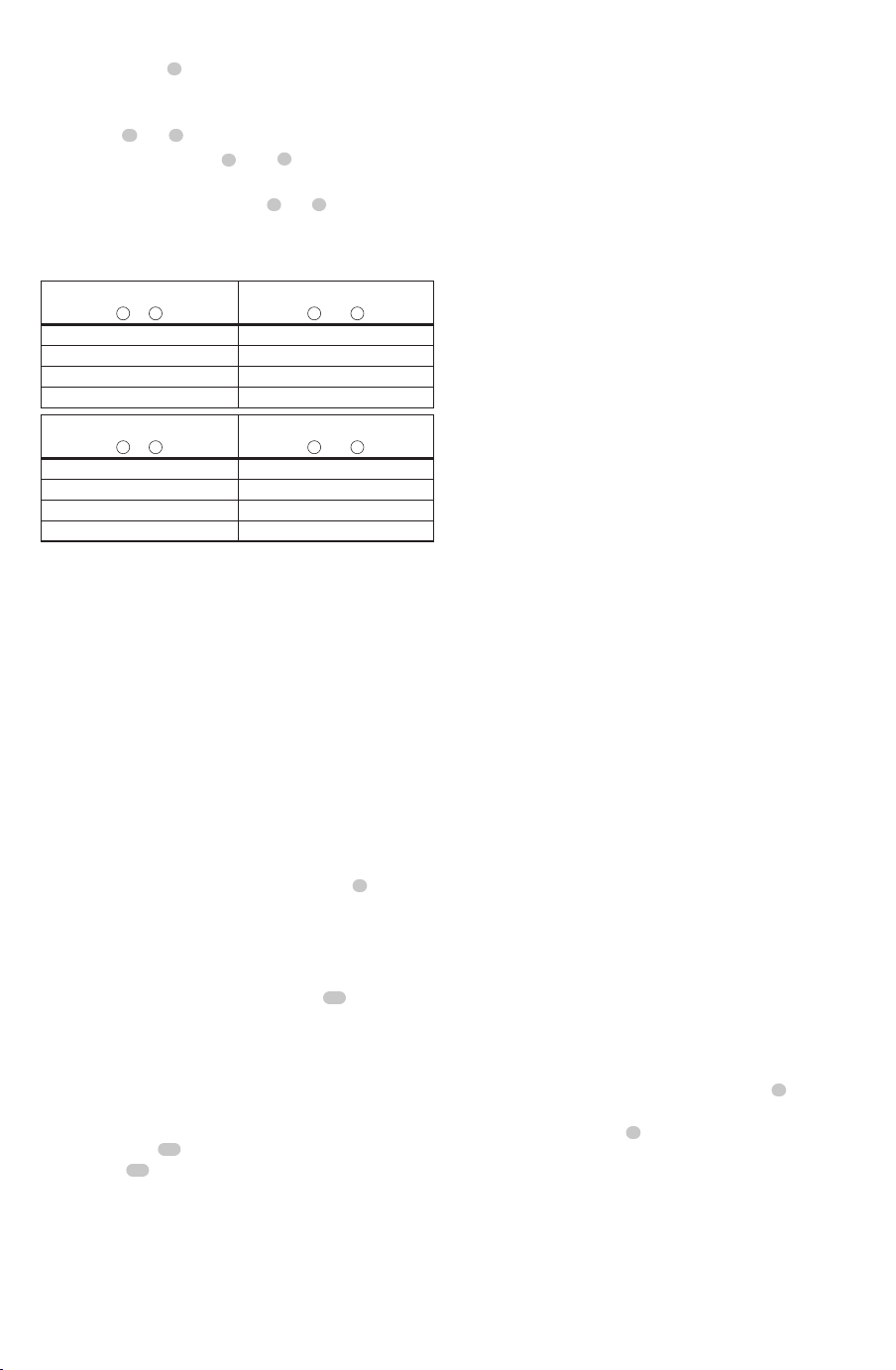

Distance from

a

to

b

Allowable Distance Between

a

and

f

14' 5/32"

17' 3/16"

20' 7/32"

23' 1/4"

Distance from

a

to

b

Allowable Distance Between

a

and

f

4.0 m 3.5 mm

5.0 m 4.4 mm

6.0 m 5.3 mm

7.0 m 6.2 mm

USING THE LASER

Leveling the Laser

As long as the laser is properly calibrated, the laser is

self-leveling. Each laser is calibrated at the factory to find

level as long as it is positioned on a flat surface within

average ± 4° of level. No manual adjustments arerequired.

If the laser has been tilted so much that it cannot self-level

(>4°), the laser beam will flash.

When the beams flash as noted above THE LASER IS

NOT LEVEL (OR PLUMB) AND SHOULD NOT BE USED FOR

DETERMINING OR MARKING LEVEL ORPLUMB.

Try repositioning the laser on a more levelsurface.

Using the Pivot Bracket (Fig.P, Q, R)

The laser has a magnetic pivot bracket (Figure P,

8

)

permanently attached to theunit.

WARNING: Position the laser and/or wall mount on

astable surface. Serious personal injury or damage to

the laser may result if the laserfalls.

• The bracket has a keyhole slot (Figure Q

10

) so it can be

hung from a nail or screw on any kind ofsurface.

• The bracket has magnets (Figure R) which allow the unit

to be mounted to most upright surfaces made of steel

or iron. Common examples of suitable surfaces include

steel framing studs, steel door frames, and structural

steel beams. Before attaching the pivot bracket against a

stud (Figure R

11

), place the Metal Enhancement Plate

(FigureR

12

) on the opposite side of thestud.

MAINTENANCE

• To maintain the accuracy of your work, check the laser

often to make sure it is properly calibrated. Refer to Field

CalibrationCheck.

• Calibration checks and other maintenance repairs may

be performed by DEWALT service centers.

• When not in use, store the laser in the kit box provided.

Do not store your laser at temperatures below -5˚F

(-20˚C or above 140˚F (60˚C).

• Do not store your laser in the kit box if the laser is wet.

The laser should be dried first with a soft dry cloth prior

tostorage.

• Cleaning exterior plastic parts may be cleaned with a

damp cloth. Although these parts are solvent resistant,

NEVER use solvents. Use a soft, dry cloth to remove

moisture from the tool beforestorage.

TROUBLESHOOTING

The Laser Does Not Turn On

• Fully-charge the battery pack and then reinstall it in the

laserunit.

• If the laser unit is exposed to extremely hot temperatures,

the unit will not turn on. If the laser has been stored in

extremely hot temperatures, allow it to cool. The laser

level will not be damaged by pressing the on/off button

before cooling to its proper operatingtemperature.

The Laser Beams Flash

The lasers are designed to self-level up to an average of

4° in all directions If the laser is tilted so much that the

internal mechanism cannot level itself, the laser beams will

flash indicating that the tilt range has been exceeded. THE

FLASHING BEAMS CREATED BY THE LASER ARE NOT LEVEL OR

PLUMB AND SHOULD NOT BE USED FOR DETERMINING OR

MARKING LEVEL OR PLUMB. Try repositioning the laser on a

more level surface.

If the laser battery pack has a low state of charge, the

beams will flash in a distinctive pattern of 3quick flashes in

1second, followed by constant light output for 4seconds.

This flashing pattern indicates that the battery pack should

be replaced with a fully charged batterypack.

The Laser Beams Will Not Stop Moving

The laser is a precision instrument. Therefore, if it is not

positioned on a stable (and motionless) surface, the laser

will continue to try to find level. If the beam will not stop

moving, try placing the laser on a more stable surface. Also,

try to make sure that the surface is relatively flat, so that the

laser isstable.

ACCESSORIES (FIG. S, T, U)

The laser is packaged with a drop ceiling bracket

9

. The drop

ceiling bracket contains a steel plate and attaches to the

magnetized pivot bracket

8

(Figure S).

The drop ceiling bracket is equipped with both 1/4 - 20and

5/8 - 11female threads on the bottom of the unit).

This thread is to accommodate current or future

DEWALT

accessories. Refer to Figure T and U for examples of

accessories sold seperately. Only use

DEWALT accessories

specified for use with this product. Follow the directions

included with the accessory.

Loading ...

Loading ...

Loading ...