Loading ...

Loading ...

Loading ...

Motor

Shat{

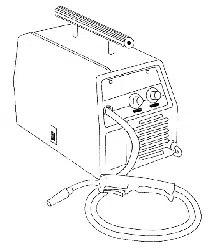

Figure 5. Drive Assembly &

Neoprene Drive Roller

6. Tighten the setscrew, while holding

the drive roller inplace

7o Remove the screws that retain the

inlet guide tube. Replace the

plastic inlet guide tube with the

supplied brass inlet guide tube

Secure screws.

Note:

The tapered side of the brass

inlet guide tube should be as

close to the rollers as possible

without touching,

It is not necessary to reinstall

the plastic inlet guide tube when

switching back to the standard

drive roller. However, if you

experience some binding,

readjust the brass inlet guide

tube slightly away from the

drive roller.

INSTALL THE WELDING

WIRE

WARNING

Electric shock can kill! Always turn

the POWER switch OFF and unplug the

power cord from the ac power source

before installing wire.,

Be very careful when removing the

welding nozzle. The contact tip on this

welder is electrically hot as long as

POWER is turned ON, Make certain

POWER is turned OFF,

t. Remove the nozzle and contact tip

from the end of the gun assembly..

2. Make sure the proper groove on

the drive roller is in place for the

wire being installed, if the proper

groove is not in place, change the

drive roller as described above,

3 Unwrap the spool of wire then find

the leading end of the wire (it goes

through a hole in the outer edge of

time spool and is bent over the

spool edge to prevent the wire from

unspooling) BUT DO NOT

UNHOOK IT YET,

4 Place the spool on the spindle in

such a manner that when the wire

comes off the spool, it will look like

the top illustration in Figure 6. The

welding wire should always come

off the top of the spool into the drive

mechanism.

Figure 6, Right and Wrong Way To

Feed Wire From Spool

5 tf you are installing a fourqnch

spool of wire, install the drive brake

hardware on the top of the spool of

wire according to Figure 7Ao If you

are installing an eight-inch spool,

install the spindle adapter and

drive brake hardware as shown in

Figure 7B. The purpose of the drive

brake is to cause the spool of wire

to stop turning at nearly the same

moment that wire feeding stops.

6 Once the drive brake hardware is

installed, set the spool tension°

With one hand, turn the wire spool

and continue turning it while

adjusting the tension on the spool.

With your free hand, tighten (turn

clockwise) the wing nut that holds

time spool in place Stop tightening

when drag is felt on the wire spool

that you are turning, then stop hand

turning the wire spool.

13

Loading ...

Loading ...

Loading ...