Loading ...

Loading ...

Loading ...

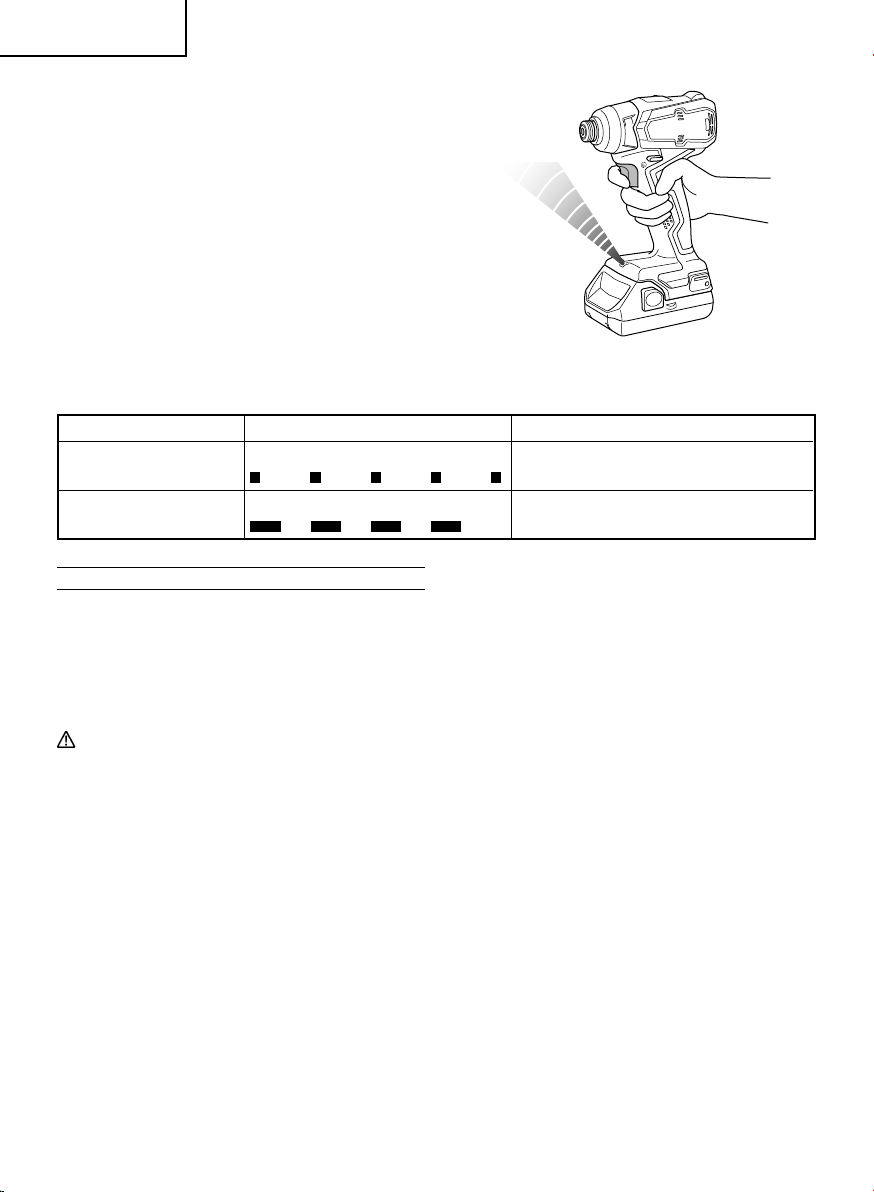

Fig. 12

10. LED light warning signals (Fig. 12)

This product features functions that are designed

to protect the tool itself as well as the battery. While

the switch is pulled, if any of the safeguard functions

activate during operation, the LED light will blink as

described in Table 5. When any of the safeguard

functions are triggered, immediately remove your

fi nger from the switch and follow the instructions

described under corrective action.

4. Work at a tightening torque suitable for the bolt under

impact

The optimum tightening torque for nuts or bolts

diff ers with material and size of the nuts or bolts. An

excessively large tightening torque for a small bolt

may stretch or break the bolt. The tightening torque

increases in proportion to the operation time. Use the

correct operating time for the bolt.

5. Holding the tool

Hold the tool fi rmly with both hands. In this case hold

the tool in line with the screw or bolt.

It is not necessary to push the tool very hard. Hold the

tool with a force just suffi cient to counteract the impact

force.

6. Confi rm the tightening torque

The following factors contribute to a reduction of the

tightening torque. So confi rm the actual tightening

torque needed by screwing up some bolts before the

job with a hand torque wrench. Factors aff ecting the

tightening torque are as follows.

(1) Voltage

When the discharge margin is reached, voltage

decreases and tightening torque is lowered.

(2) Operating time

The tightening torque increases when the operating

time increases. But the tightening torque does not

increase above a certain value even if the tool is

driven for a long time.

OPERATIONAL CAUTIONS

1. Resting the unit after continuous work

After use for continuous bolt-tightening work, rest the

unit for 15 minutes or so when replacing the battery.

The temperature of the motor, switch, etc., will rise

if the work is started again immediately after battery

replacement, eventually resulting in burnout.

CAUTION

Do not touch the metal parts, as it gets very hot

during continuous work.

2. Cautions on use of the speed control switch

This switch has a built-in, electronic circuit which

steplessly varies the rotation speed. Consequently,

when the switch trigger is pulled only slightly (low

speed rotation) and the motor is stopped while

continuously driving in screws, the components of

the electronic circuit parts may overheat and be

damaged.

3. Use a tightening time suitable for the screw

The appropriate torque for a screw diff ers according

to the material and size of the screw, and the material

being screwed etc., so please use a tightening time

suitable for the screw. In particular, if a long tightening

time is used in the case of screws smaller than 5/16"

(M8), there is a danger of the screw breaking, so

please confi rm the tightening time and the tightening

torque beforehand.

Table 5

Safeguard Function LED Light Display Corrective Action

Overburden Protection

On 0.1 second/off 0.5 second

Remove the cause of the overburdening.

Temperature Protection

On 0.3 second/off 0.3 second

Allow the tool and battery to thoroughly cool.

14

English

0000WH18DDXmetabo.indb140000WH18DDXmetabo.indb14 2020/05/2811:33:352020/05/2811:33:35

Loading ...

Loading ...

Loading ...