Loading ...

Loading ...

Loading ...

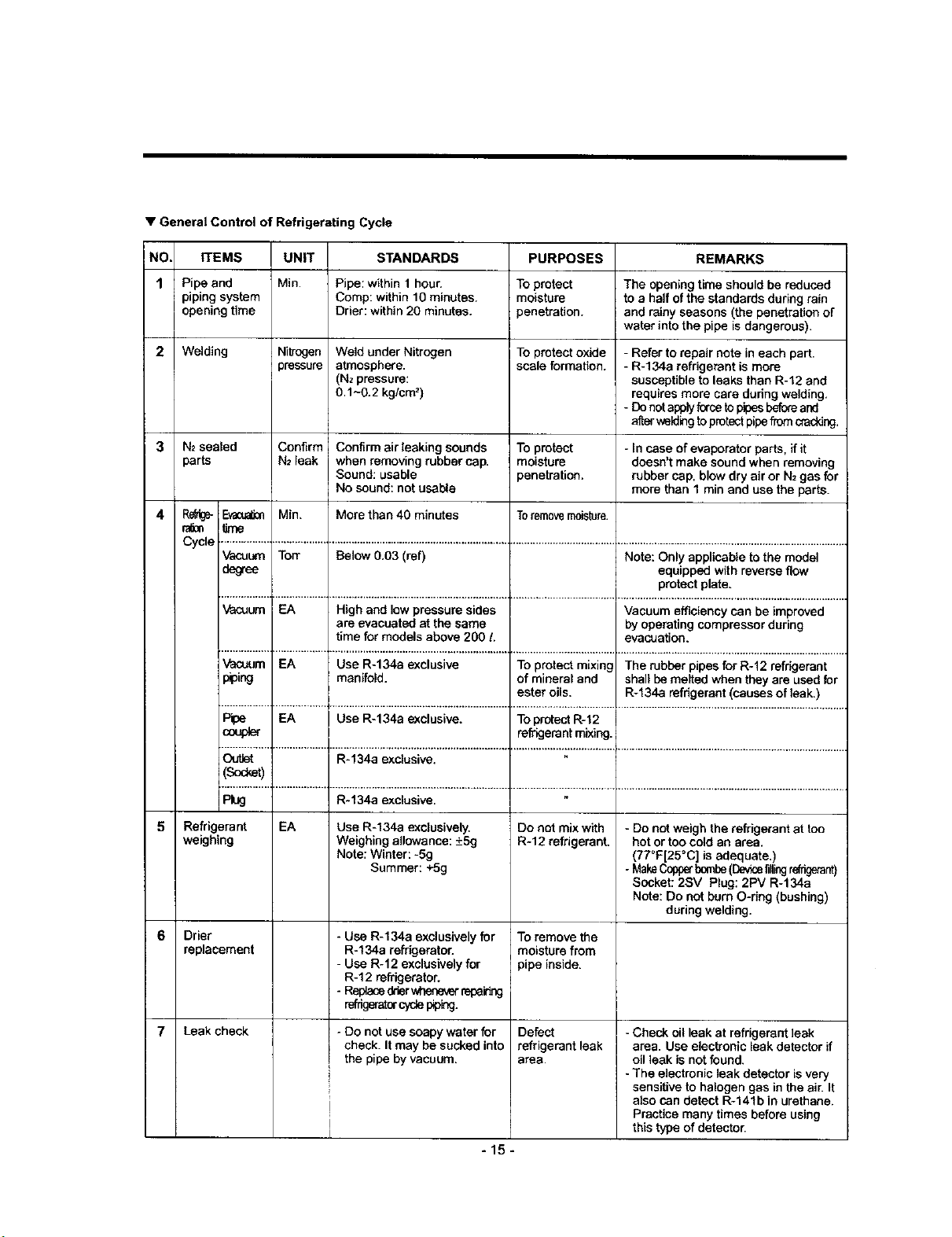

•General Control of Refrigerating Cycle

NO.

1

4

5

6

7

EEMS

Pipe and

piping system

opening time

Welding

N_sealed

parts

RefUge-_

r'a_0n time

UNIT

Min.

STANDARDS

Pipe: within 1hour.

Comp: within 10 minutes.

Drier: within 20 minutes.

Nitrogen Weld under Nitrogen

)ressure atmosphere.

(Nz pressure:

0.1-0.2 kg/cm z)

Confirm Confirm air leaking sounds

N2 leak when removing rubber cap.

Sound: usable

No sound: not usable

Min. More than 40 min_es

PURPOSES

TOprotect

moisture

penetration.

To protect oxide

scale formation.

To pre_ct

moi_ure

penetmtion+

Toremovemoisture.

REMARKS

The opening time should be reduced

to ahalf of the standards during rain

and rainy seasons (the penetration of

water into the pipe is dangerous).

- Refer to repair note in each part.

- R+134a refrigerant is more

susceptible to leaks than R-12 and

requires more care during welding,

- Do not applyferce to pipes beforeand

a_erwelding toprotect pipe from cracking.

- in case of evaporator parts, if it

doesn't make sound when removing

rubber cap, blow dry air or N2gas for

more than 1 rain and use the parts.

Cycle ................._..................._...............................................................÷...................................._................................................................................

Vacul._m Tort Below 0.03 (ref) Note: Only applicable to the model

deg'ee equipped with reverse flow

protect plate.

................. *_.................. 1............................................................... ÷.................................... i ................................................................................

Vacuum =EA High and low pressure sides Vacuum efficiency can be improved

are evacuated at the saree by operating compressor during

time for models above 200 Levacuation.

Vacuum EA Use R-134a exclusive To protect mixing The rubber pipes for R-12 refrkJerant

p_oing manifold, of mineral and shall be melted when they are used for

ester oils. R-134a refrigerant (causes of leak.)

................. _ ................. 1............................................................... +.................................... +..............................................................................

Pipe EA Use R-134a exclusive. To protect R-12

coupler refrigerant mixing.

................. i................... 1............................................................... ÷.................................... _................................................................................

Ou*Jet R-134a exclusive.

(Sod_et)

Plug R*134a exclusive.

Refrigerant

weighing

Drier

replacement

Leak check

EA Use R-134a exclusively.

Weighing allowance: +5g

Note: Winter: -5g

Summer: +5g

-Use R-134a exclusively for

R-134a refdgeratoc

- Usa R-12 exclusivelyfor

R-12 refrigerator.

-Replacedrierwheneverrepaiing

refrigeratorcyclepiping.

-Do not use soapy water for

i check. It may be sucked into

the pipe by vacuum.

I

Donot mix with

R+I2refrigerant,

Toremove the

moisture from

pipeinside,

Defect

refrigerant leak

area.

-Donot weigh the refrigerant at too

hot or too cold an area.

(77°F[25=C] Js adequate.)

- MakeCopperbombe(Devicefillingrefrigerant)

Socket: 2SV Plug: 2PV R-134a

Note: Do not bum O-dng (bushing)

during welding.

-Check oil leak at refrigerant leak

Iarea. Use electronic leak detector if

oil leak is not found.

-The electronic leak detector isvery

sensitive to halogen gas in the air. It

also sen detect R-141b in urethane.

Practice many times before using

this type of detector.

I-15-

Loading ...

Loading ...

Loading ...