Loading ...

Loading ...

Loading ...

802259 - B, BA, BHA, BAHA, Quick Start Guide - July 2015 - V2.00

Note: Remove any plugs from the top of the undersink unit connections and Install the

mains water braided hoses to the undersink unit before locating the unit in place..

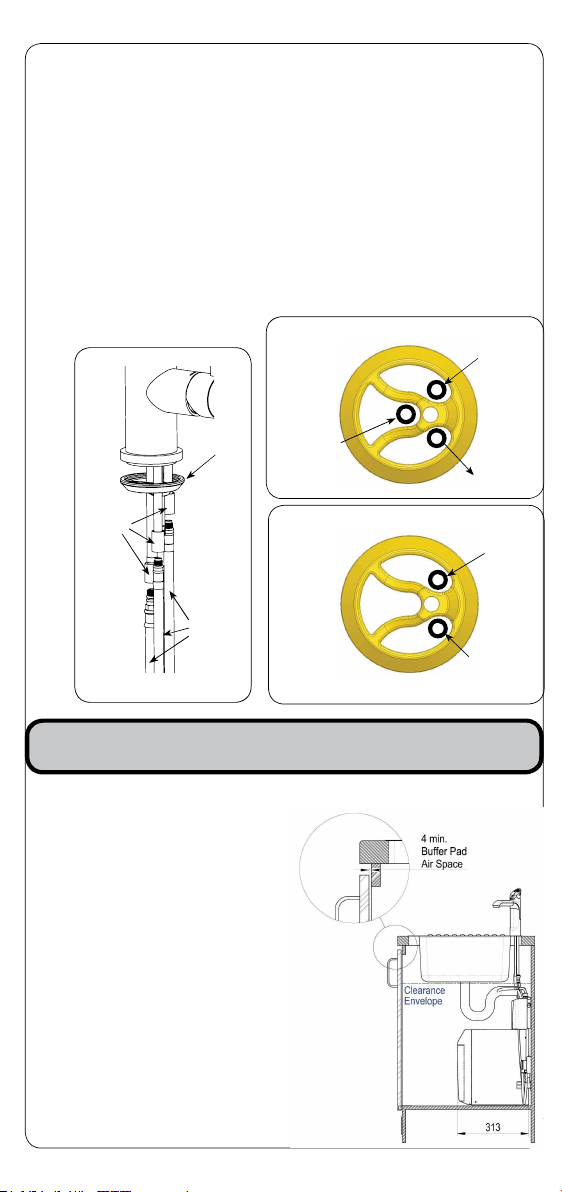

OPEN Position

CLOSED Position

ON

OFF

Stop cock

operation

Have a 10L bucket or similar container (not

supplied) at the ready to hold a quantity of

water that will be ejected while the Filter

Flush Mode is in operation. Open the filter

access door on the front of the HydroTap

and the filter cartridge will be exposed.

Located to the rear RHS of the cartridge is a

flush line, approx 600mm long and the flush

line stop cock. Place the valve end of the

flush line into the 10L bucket or container.

1.

Turn the stop cock ON

2.

Press [Start] button to start filter flush.

3.

Allow at least 10 litres of water to flush

through the filter.

4.

Once the filter flush is finished, Turn the stop

cock OFF then press [Stop] to end filter flush

mode.

Flow Calibration:

1.

Press [Next] and the View screen will

show the Flow calibration mode.

2.

Press the [Start] button and the tank will

first empty then fill. Upon completion the

actual pulse will be displayed. Check this

reading is within the limits

Boiling Calibration:

1.

Press [Next] for the Boiling Calibration

screen.

2.

Press the calibration button and the system

will commence the Boiling calibration

procedure. This will take aprox 5-6 minutes.

3.

Upon completion, a Booster reminder screen

will appear and allow you to return home by

pressing the [Home] button.

4.

Check the Date and Time settings (See

section G of the user guide)

To enable the Booster: (when installed)

• Press the [MENU] button for main menu.

• Press the [Install] button.

• Press the [Booster] button.

• In the next screen, press YES to enable the

Booster.

• Turn the Booster ON

• Water must be run through the Booster for

a min of 30 seconds, before the heater will

activate.

• Dispense boiling water for 30 seconds and

check the Booster outlet hose is warm when

the boiling water tank is replenishing.

Note: Failing to make the correct selection for the

“Booster”, will affect product performance.

Filter Flush:

STEP 5 -

Commissioning

Before Commissioning:

• Turn ON the water and check for any leaks.

• Turn the power ON at the GPO and at the side of the undersink unit

• If fitted, ensure the Booster is turned OFF. (The Booster is enabled after

commissioning)

• Familiarise yourself with the operation of the Tap, in preparation for use (See User

Guide)

• Follow the Installation instructions below (and review Section C of the User Guide).

• After commissioning, the system may be customised by selecting further options in

Section G - Settings, within the User Guide.

STEP 3 -

Booster Heater

STEP 4 -

HydroTap Unit

STEP 2 -

Ventilation

Note: For alternative solutions, refer to section 2 of the main instructions

STEP 5 -

Commissioning

mount base

Horizontally

Note: All

silicon tubes

must be cut

to size. They

must have a

constant fall

back to the

unit.

RED

C

L

EA

R

BLUE

BRAIDED

POWER

CORD

USB

MAINS

IN

MIXER

OUT

MIXER

IN

BOILING

OUT

BYPASS

IN

VENT

BYPASS

OUT

AMBIENT

OUT

Vented braided hose positions

BLUE to

Mixer IN

WHITE

Mains IN

RED from

Mixer OUT

Mains braided hose positions

HOT IN

from HWS

Underside view

BLUE

Mains IN

RED

• Fit the seal ring to the base of the tap and apply a light smear of silicone sealant to

ensure a watertight seal

• Mount the tap on top of the cut out hole after passing the usb cable and tubes through

the 50mm hole

• Thread the cable and silicon tubes through the circular clamp block (Check the tube

colour matches with the coloured dots on the clamp block). (See below)

• Clamp the assembly in position using the threaded nut and clamp block

• Working from inside the cupboard, attach the braided hoses to the tube extensions

(ensure the seals on the end of the hoses are lubricated). Check the correct position

for Hot and Cold connections by matching the colours on the braided hoses with the

coloured markings on the copper extension tubes. (See below)

• Test for leaks after all the connections have been secured.

CLAMP

BLOCK

Braided

hoses

Extension

tubes

Typical Vented assembly

Note: Mains hose length is 750mm and the Plug and Cord length is 1800mm

Position the under sink unit close to the outlet tap, within reach of the hose and cord

lengths supplied.

Ensure their is at least an unobstructed 50mm air gap on both sides of the undersink unit.

Note: The tube lengths are matched to the pumps performance and therefore CANNOT

be lengthened.

BA160 and BA240 connections shown. For other configurations, see the main

installation instructions

Note 1: water connection:

Blue marking - water in;

Red marking - water out.

The tubes and hoses cannot be

lengthened.

Note 2: Position the booster

according to the flexible hose

and cable lengths supplied.

Keep the Booster as close as

possible to the undersink unit

inlet/ outlet fittings.

Note 3: Ensure the Booster

heater is mounted in an

upright position (as shown) with

a horizontal base.

Note 4: For mounting details,

refer to section 3 of the main

instructions

It is important to adjust both cupboard door

hinges and attach rubber door buffers to

the doors to create a 4 mm air-gap between

the doors and the cupboard. This is the

minimum ventilation requirement for low

usage installations.

For high use applications, where the

cupboard space temperature is near 35°C,

or higher, a vent kit must be fitted. (Contact

your local service centre for availability).

Proper air circulation must be provided

for all models. The system will operate

correctly only if the recommended air

gaps are achieved during installation.

Loading ...

Loading ...