Loading ...

Loading ...

Loading ...

English 10

• After the vacuum drying is finished, charge the additional refrigerant

in its liquid state through the liquid stop valve service port.

Taking into account following instructions:

1.

Check that gas and liquid stop valves are closed.

2.

Charge the specified amount of refrigerant.

• If the outdoor unit is not in operation and the total amount cannot be

charged, follow the procedures for additional refrigerant charge

shown below.

• Make sure to use installation tools you exclusively use on R410A

installations to withstand the pressure and to prevent foreign materi-

als from mixing into the system.

• Procedures for charging additional refrigerant.

See the “Cautions on service” label on the back of the front panel for the

settings for operation after replenishing refrigerant.

1. Open the gas line stop valve (leaving the liquid line stop valve, valve

A in the diagram above, close) and perform the operation to add the

refrigerant.

2. Once the appropriate amount of refrigerant is in, press the confirma-

tion button (BS3) on the outdoor unit PC board (A1P), and stop oper-

ation.

3. Open the stop valves quickly (both liquid and gas line valves).

(This must be done quickly to avoid the possibility that the pipe might

burst.)

•

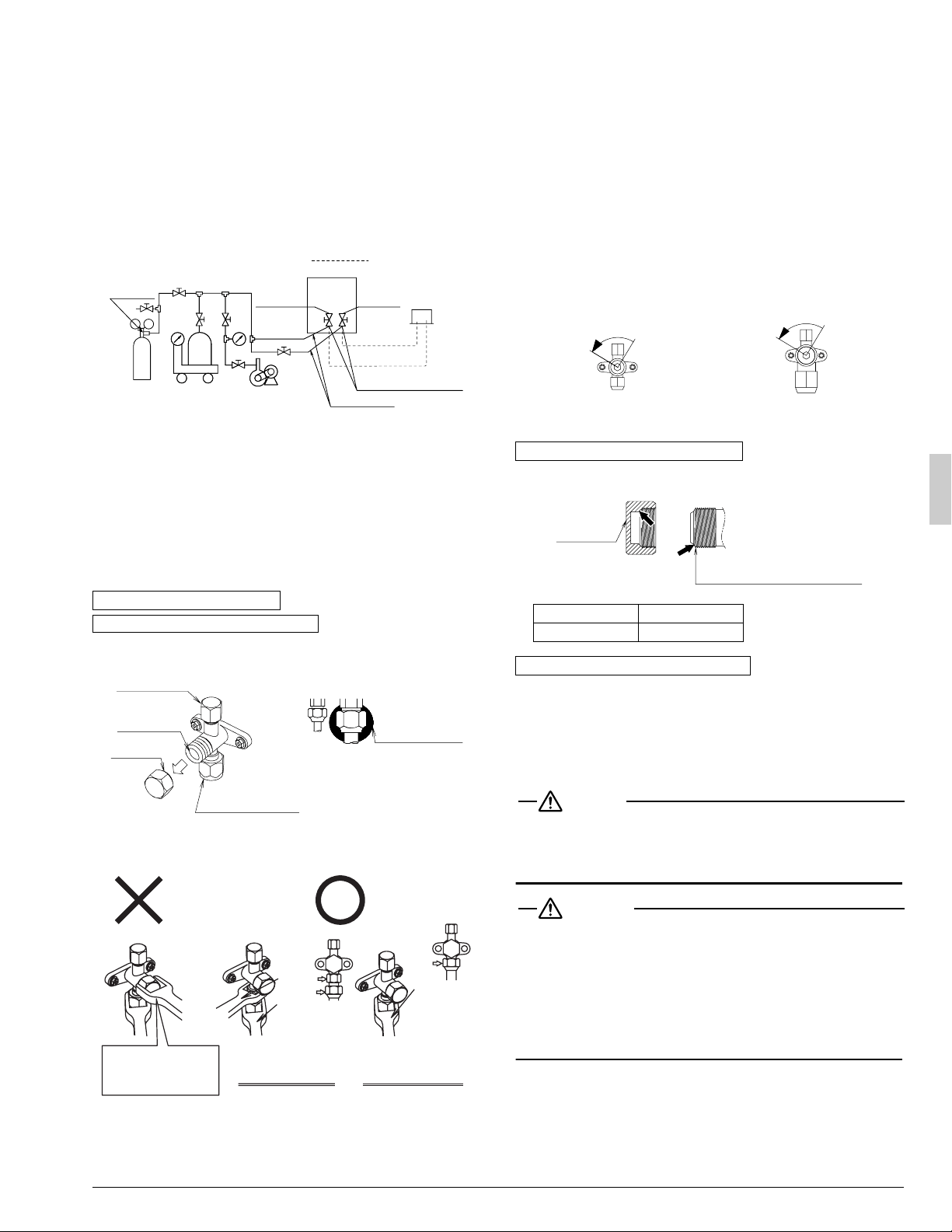

The figure below shows the name of each part required in handling the

stop valve

. At the time of shipment, the

stop valve

is closed.

•

If only a torque wrench is used to loosen or tighten the flare nut, the

side plate may be distorted. Make sure to fix the

stop valve

with a

spanner, then loosen or tighten the flare nut with a torque wrench.

• When it is expected that the operating pressure will be low (for exam-

ple, when cooling will be performed while the outside air temperature

is low), seal sufficiently the flare nut in the stop valve on the gas line

with silicon sealant to prevent freezing.

[Stop valve operation method]

Prepare hexagon wrenches (whose size is 4 mm and 6 mm).

How to open the stop valve

1. Insert a hexagon wrench into the valve stem, and turn the valve

stem counterclockwise.

2. When the valve stem cannot be turned any more, stop turning.

Now, the valve is open.

How to close the stop valve

1. Insert a hexagon wrench into the valve stem, and turn the valve

stem clockwise.

2. When the valve stem cannot be turned any more, stop turning.

Now, the valve is closed.

• The valve is sealed in the arrow area. Take care not to damage the

arrow area.

•

After handling the valve, make sure to tighten the valve cap securely.

• Use charge hose equipped with push in the work.

• After the work, make sure to tighten the valve cap securely.

Tightening torque.....8.5~10.3 ft·lbf

7. ELECTRIC WIRING WORK

DANGER

•

Do not ground units to water pipes, telephone wires or lightning rods

because incomplete grounding could cause a severe shock hazard

resulting in severe injury or death, and to gas pipes because a gas leak

could result in an explosion which could lead to severe injury or death.

WARNING

• Disconnect all power to unit to avoid possible electric shock

during installation.

• Use only specified wire and connect wires to terminals tightly. Be

careful that wires do not place external stress on terminals. Keep

wires in neat order so as to not to obstruct other equipment. Incom-

plete connections could result in overheating, and in worse cases,

electric shock or fire.

For the details, refer to “7-3 Power supply wiring connection pro-

cedure”.

Stop valve operation method

Cautions on handling the stop valve

Nitrogen

Dotted lines

represent

field piping

Cylinder

Stop valve service port

Vacuum pump

Weighing

scale

Charge hose

R410A

Pressure

reducing

valve

Outdoor unit

Indoor unit

Liquid line

Gas line

(Siphon system)

Valve A

Valve cap

Service port

Field piping

connection part

Valve stem

Silicon sealant

(Take care not to generate cavity.)

Stop valve of two

hangs structure

Stop valve of one

hang structure

Torque

wrench

Torque

wrench

Spanner

Spanner prohibition

to valve cap and

body part

Cautions on handling the valve cap

Liquid line Gas line

10.0~12.2 ft·lbf 16.6~20.3 ft·lbf

Cautions on handling the service port

<Liquid line>

<Gas line>

Opening direction

Opening direction

Valve cap

Stop valve

(valve cap attachment area)

01_EN_3PN07193-7L.fm Page 10 Thursday, February 16, 2012 8:22 PM

Loading ...

Loading ...

Loading ...