Loading ...

Loading ...

Loading ...

14

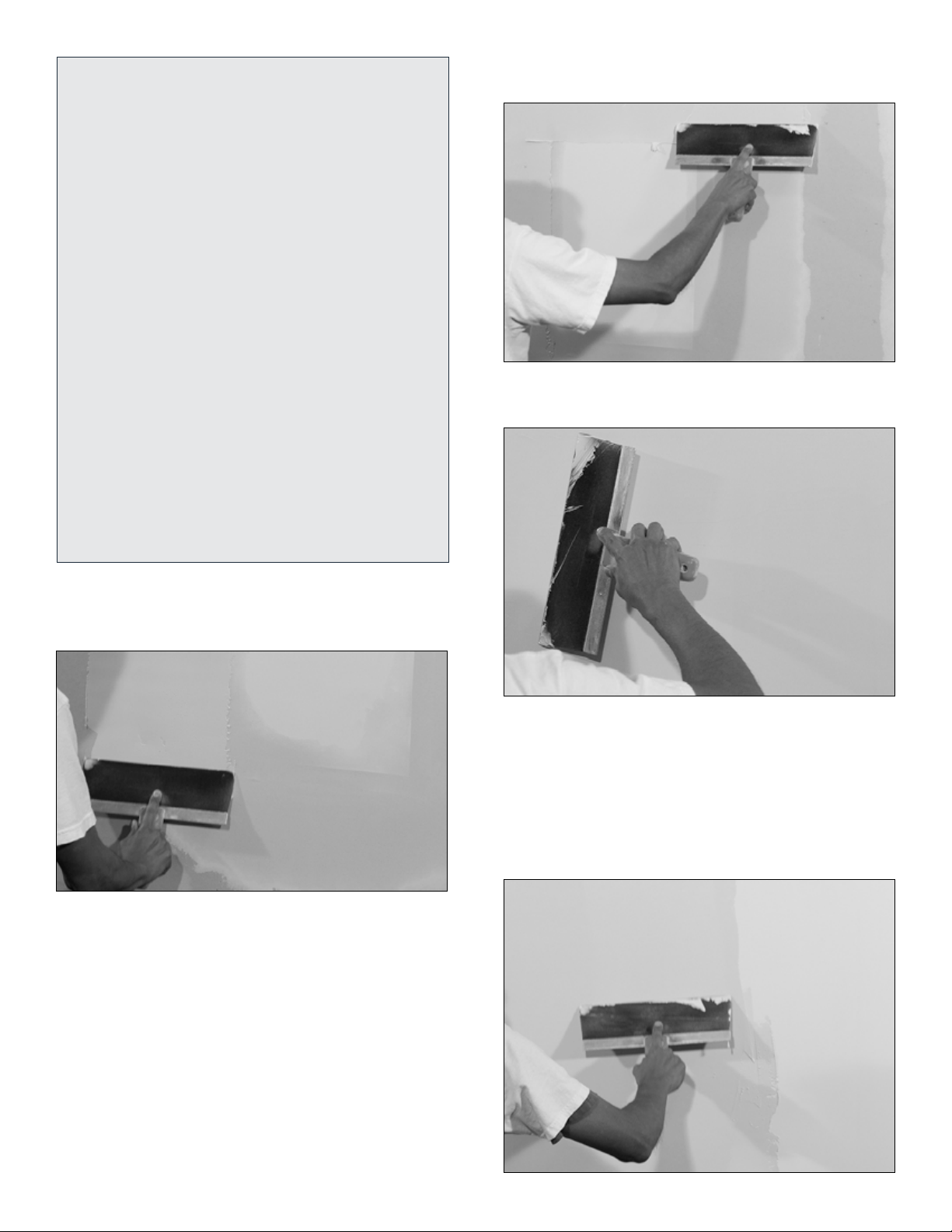

10. Apply a second coat of topping compound covering

the entire surface of the speaker and all adjoining

surfaces.

11. Compound buildup on the active surface of the

speaker should not exceed 3mm (1/8”).

12. Detail the compound to minimize tool marks.

13. Allow each layer to fully cure. This can take 12–24

hours.

14. Build more coats as necessary to achieve desired

finish. Each successive coat should be thinner than

the last. The final coat should be a very light skim

coat application.

FINISH THICKNESS GUIDELINES

Sound quality and installation durability will be

adversely eected if finish materials are applied too

thick.

TOTAL FINISH THICKNESS FOR OPTIMAL

PERFORMANCE: 1.0mm to 1.5mm (3/64” to 1/16”)

MAXIMUM TOTAL FINISH THICKNESS: 3mm (1/8”)

Validate finish thickness using the Sonance DG-1

depth gauge (SKU 93491).

Do not use hard-setting or sti materials over the

surface of invisible speakers, such as fast-setting

drywall mud (“hot mud”), genuine Venetian plaster,

stucco, metal panels, tile, etc. Use only flexible

materials to finish invisible speakers.

When using flexible sheet materials such as

wallpaper or veneer, ensure that the total thickness

of any drywall compound, adhesives, and the

finishing substrate itself does not exceed 3mm

(1/8”). For wood veneer finishes, use only 20mil

(0.5mm) veneer with paper backing.

Loading ...

Loading ...

Loading ...