Loading ...

Loading ...

Loading ...

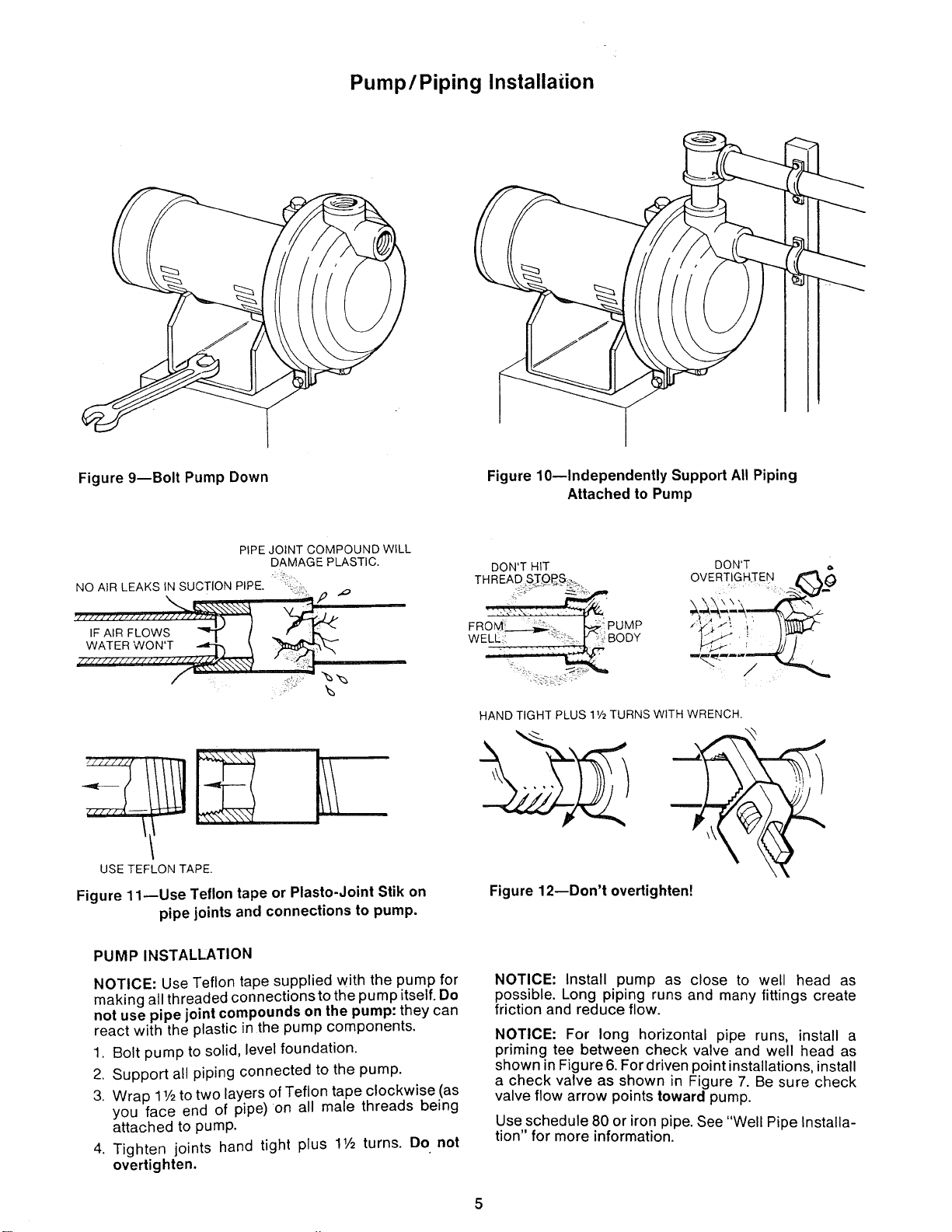

Pump/Piping Installation

Figure 9--Bolt Pump Down

Figure 10--Independently Support All Piping

Attached to Pump

PIPE JOINT COMPOUND WILL

DAMAGE PLASTIC.

NO AIR LEAKS IN SUCTION PIPE. "_.'(: ,

'W--)

WATER WON'T _ \ _ _"

/l!ll!//l///(l!!!//!/I/P / * -,'{[

USE TEFLON TAPE.

Figure 11--Use Teflon tape or Plasto-Joint Stik on

pipe joints and connections to pump.

DON'T HIT

THREAD STO_S _

W BODY

DON'T

OVERT!GHZEN _,_

HAND TIGHT PLUS 11/2TURNS WITH WRENCH.

Figure 12--Don't overtighten!

PUMP INSTALLATION

NOTICE: Use Teflon tape supplied with the pump for

making all threaded connections to the pump itself. Do

not use pipe joint compounds on the pump: they can

react with the plastic in the pump components,

1. Bolt pump to solid, level foundation.

2. Support all piping connected to the pump.

3. Wrap 11/2to two layers of Teflon tape clockwise (as

you face end of pipe)on all male threads being

attached to pump.

4. Tighten joints hand tight plus 1Vz turns. Do not

overtighten.

NOTICE: Install pump as close to well head as

possible. Long piping runs and many fittings create

friction and reduce flow.

NOTICE: For long horizontal pipe runs, install a

priming tee between check valve and well head as

shown in Figure 6. For driven point installations, install

a check valve as shown in Figure 7. Be sure check

valve flow arrow points toward pump.

Use schedule 80 or iron pipe. See "Well Pipe Installa-

tion" for more information.

Loading ...

Loading ...

Loading ...