Loading ...

Loading ...

Loading ...

ENGLISH

10

• Breathing exhaust fumes will cause serious

injury or death! Engine exhaust contains carbon

monoxide, an odorless and deadlygas.

• Operate pressure washer in a well-ventilated

area. Avoid enclosed areas such as garages,

basements,etc.

• Never operate unit in or near a location occupied

by humans oranimals.

WARNING: Risk of fire, asphyxiation and burning.

Never fill fuel tank when engine is running or hot. Do

not smoke when filling fueltank.

• Never fill fuel tank completely. Fill tank to

1/2" (12.7 mm) below bottom of filler neck to

provide space for fuel expansion. Wipe any fuel

spillage from engine and equipment before

startingengine.

• DO NOT let hoses come in contact with very hot

engine muffler during or immediately after use

of your pressure washer. Damage to hoses from

contact with hot engine surfaces will NOT be

covered bywarranty.

NOTICE: NEVER pull water supply hose to move

pressure washer. This could damage hose and/or

pumpinlet.

• DO NOT use hot water, use cold wateronly.

• Never turn water supply off while pressure washer

engine is running or damage to pump willresult.

• DO NOT stop spraying water for more than two

minutes at a time. Pump operates in bypass mode

when spray gun trigger is not pressed. When the

temperature inside the pump rises too high the

thermal relief valve (

20

, Fig.J) will open and

release a gush of water in an effort to lower the

temperature inside the pump. The thermal relief

valve will then close. If pump is left in bypass mode

for more than two minutes internal components

of the pump can bedamaged.

Fig. J

20

Start-up Procedure (Fig. A, K–Q)

1. In a well-ventilated outdoor area, add fresh, high-

quality, unleaded gasoline with a pump octane rating of

86 or higher. Do not overfill. Wipe up spilled fuel before

starting the engine. Refer to engine instruction manual

for correctprocedure.

IMPORTANT: Ethanol Shield™ (sold separately) is a fuel

stabilizer that helps eliminate and prevent ethanol

related problems in power equipment. Follow the

instructions on the container and add to thegasoline.

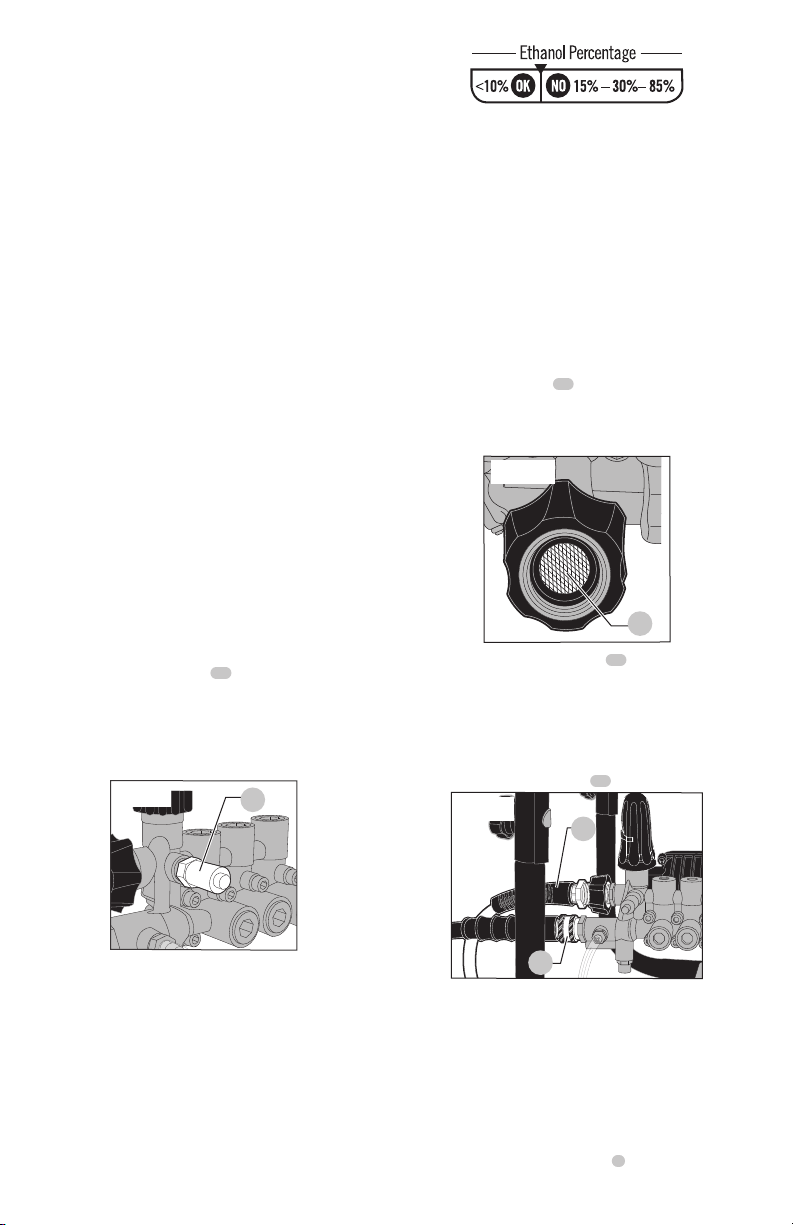

NOTICE: Use of fuels with greater than 10% ethanol

are not approved for use in this product per EPA

regulations and will damage the unit and void

thewarranty.

2. Check engine oil level. Refer to the engine instruction

manual for correctprocedure.

3. Check pump oil level. The oil level should come to the

dot in the middle of the sight glass. Refer to the Pump

paragraph underMaintenance.

4. Connect the water hose to the water source. Turn the

water source on to remove all air from the hose. When

a steady stream of water is present, turn the water

sourceoff.

5. Verify the filter screen

21

is in water inlet of pump. The

convex side facesout.

NOTICE: Failure to use an inlet screen filter may cause

damage to pump components and voidwarranty.

Fig. K

21

6. Connect the cold water source

22

to pump inlet.

NOTE: Water source must provide a minimum of 5

gallons per minute at 20 psi (138 kPa).

WARNING: To reduce the possibility of contamination

always protect against backflow when connected to a

potable watersystem.

7. Connect high pressure hose

16

to pumpoutlet.

Fig. L

22

16

8. If applying a chemical or cleaning solution, refer to

Chemicals and CleaningSolvents.

9. Turn the water sourceon.

NOTICE: Risk of property damage. Failure to do so

could cause damage to thepump.

10. Remove all air from the pump and high pressure hose

by depressing trigger until a steady stream of water

ispresent.

11. Turn the engine ON/OFF switch

8

to the ONposition.

Loading ...

Loading ...

Loading ...